A kind of granulation method of microbial fertilizer

A technology of microbial fertilizer and granulation, which is applied in microbial treatment, biological organic part treatment, fertilization device, etc., can solve the problems of affecting fertilizer fertility, poor continuity, and bacterial death, so as to reduce the invasion and protection of bacteria. The effect of bacterial erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A method for granulating microbial fertilizer, comprising the following steps;

[0035] Step S1: uniformly mix livestock and poultry manure and crushed straw according to a mass ratio of 1:1 to obtain an organic matter mixture, add water to the organic matter mixture and mix evenly to obtain a culture medium with a water content of 30% to 50%;

[0036] Step S2: after the culture material is obtained in S1, after the medium is cooled, the bacterial population is put into the medium, and the bacterial population includes nitrifying bacteria, yeast, photosynthetic bacteria, rhizobia, phosphorus bacteria, potassium bacteria and spores. After fully mixing, place it in a reactor at 20-30°C for fermentation and cultivation;

[0037] Step S3: Transfer the mixed solution obtained in S1 to a fermentation reactor, stir thoroughly, and ferment at 27-33°C for 5-15 days to obtain a fermented product;

[0038] Step S4: filter the fermented product to obtain a dehydrated fermented pro...

Embodiment approach

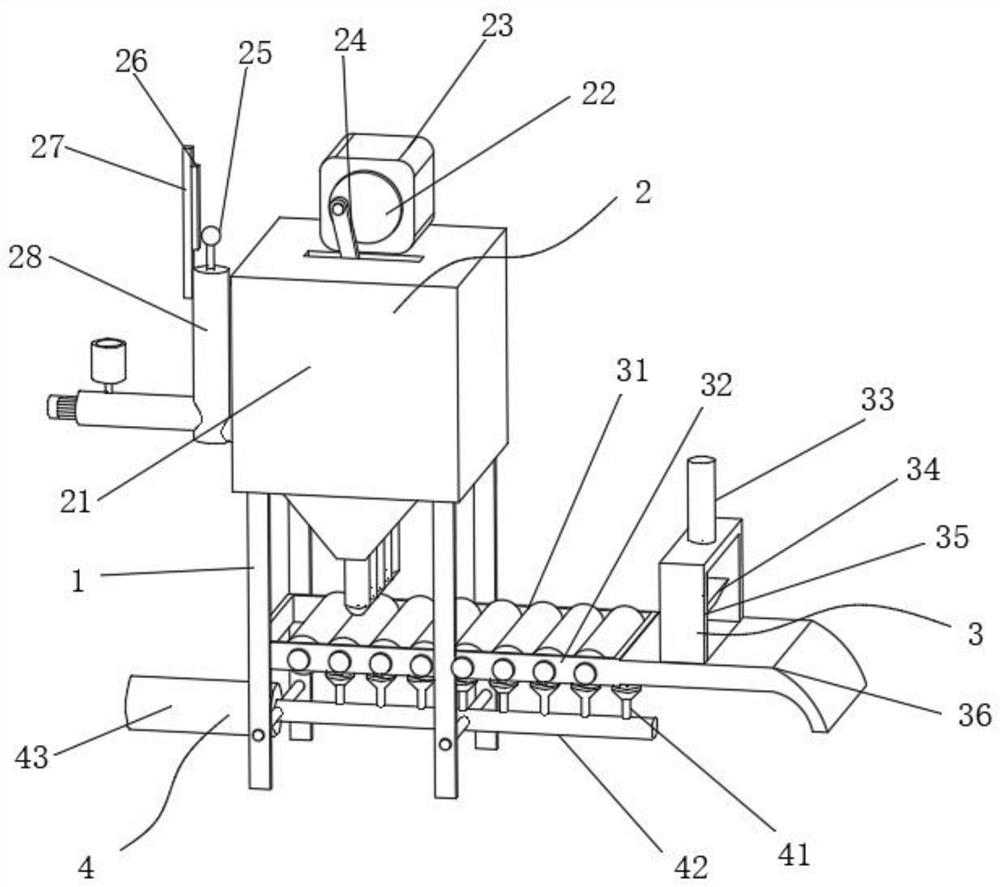

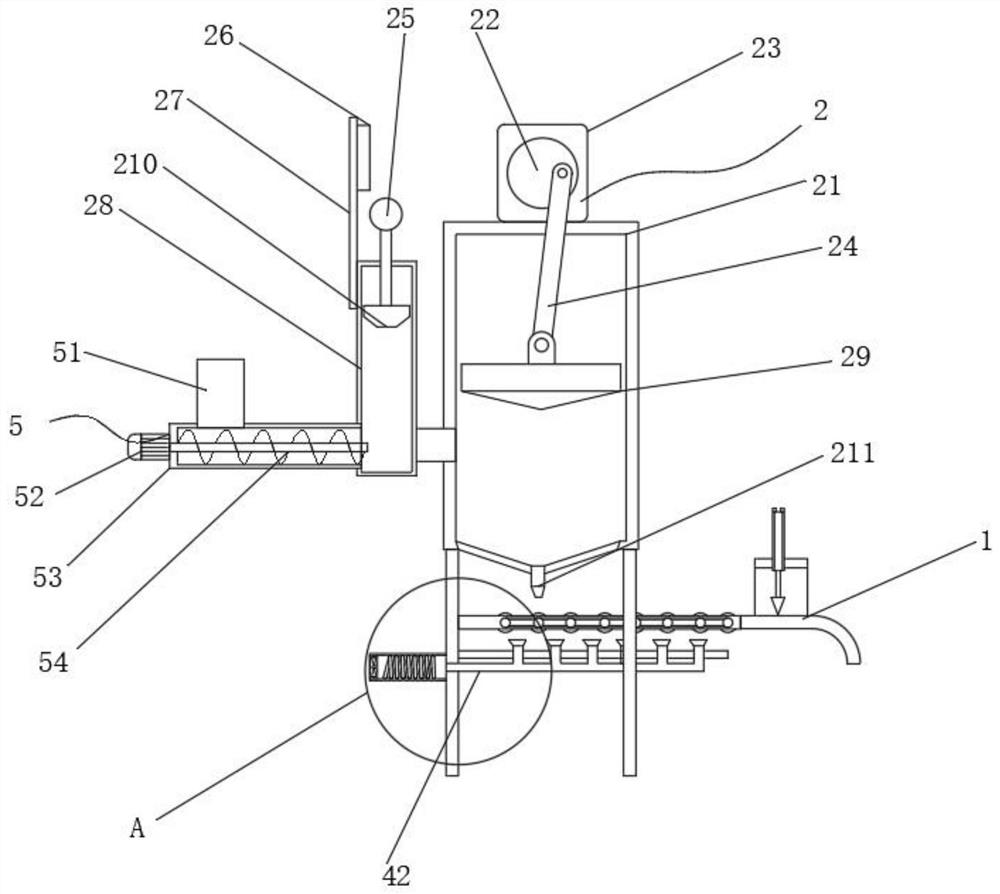

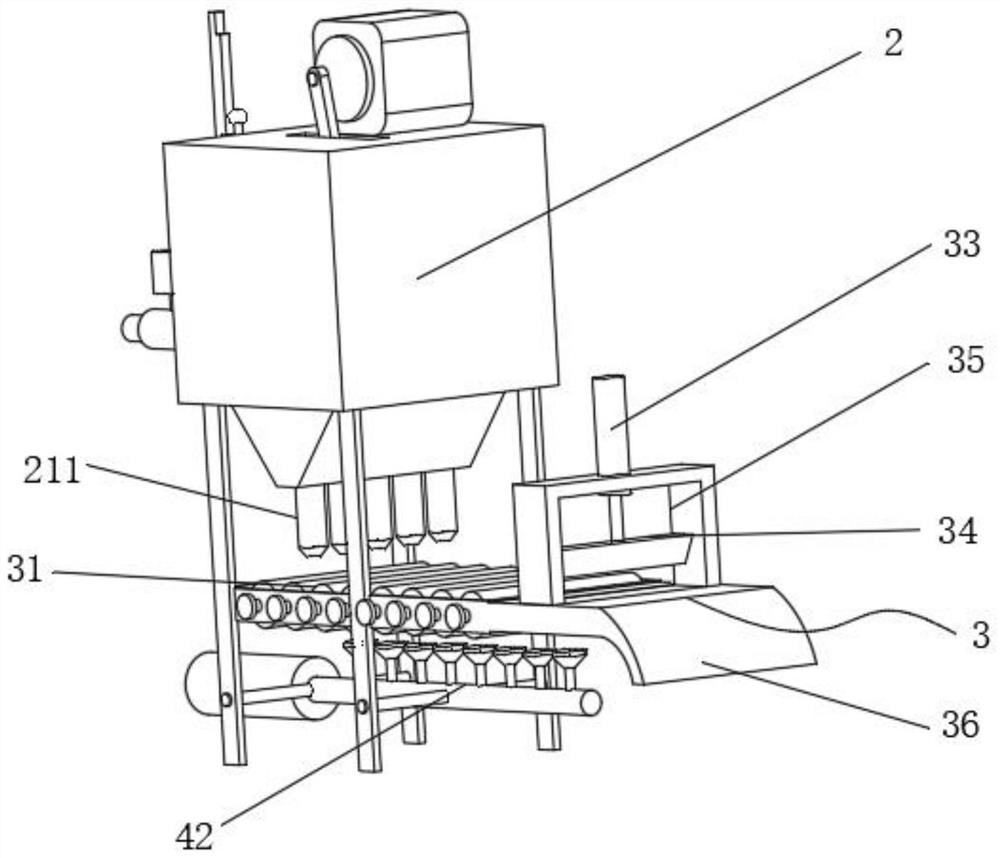

[0047] As a kind of embodiment of the present invention, dividing assembly 3 comprises conveying roller 31, roller frame 32, cutting cylinder 33, cutting knife 34, cutting frame 35 and deflector 36, and roller frame 32 is erected on the supporting frame 1, and roller frame The interior of 32 is equipped with a plurality of conveying rollers 31 side by side, deflector 36 is welded on one side of conveying roller 31, and the top of deflector 36 is equipped with cutting frame 35, and cutting cylinder 33 is installed on cutting frame 35, and cutting cylinder The bottom end of the action bar of 33 is equipped with cutting knife 34.

[0048] As an embodiment of the present invention, the drying structure 4 includes an air nozzle 41, an air duct 42, an air intake pipe 43, an ultraviolet lamp tube 44, and an air intake fan 45. The air duct 42 is erected on the bottom of the support frame 1, and the air intake duct 43 is fixed. Connected to the end of the air guide pipe 42, an air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com