A Six-Stage Formation Process of High Stability High Voltage Anode Foil

A high-stability, anode foil technology, applied in the field of electrode foil, can solve the problems of inability to improve the hydration resistance and stability of the anode foil, the limited effect of the hydration resistance of the anode foil, flash fire on the surface of the anode foil, etc., to achieve high capacity, The effect of increasing the upper limit of voltage and high bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

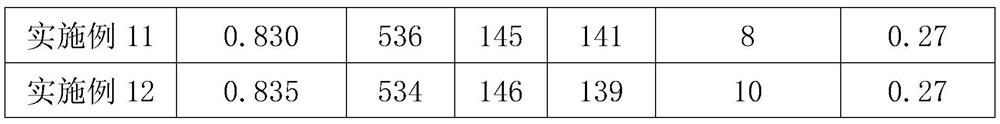

Examples

Embodiment 1

[0100] (1) Primary feed: the conductive silver roller supplies power to the primary and secondary forming feeds.

[0101] (2) Boiling in high temperature water: soak the foil in water above 95°C for 11 minutes.

[0102] (3) Primary chemical synthesis: use a forming solution containing 2.0g / L ammonium dihydrogen phosphate, 1.0g / L citric acid, 1.0g / L triammonium citrate and 0.05g / L sodium hypophosphite for primary chemical synthesis , current density 80mA / cm 2 , the voltage is 150V, the formation time is 5min30s, and the processing temperature is 90°C.

[0103] (4) Secondary chemical formation: use a forming solution containing 1.0g / L ammonium dihydrogen phosphate, 0.6g / L citric acid, 0.5g / L triammonium citrate and 0.05g / L sodium hypophosphite for secondary chemical formation , current density 80mA / cm 2 , the voltage is 300V, the formation time is 5min30s, and the processing temperature is 90°C.

[0104] (5) Tertiary chemical conversion: use a forming solution containing 0.2...

Embodiment 2

[0107] The method of formation is the same as in Example 1, the difference is that the third stage forming liquid:

[0108] Tertiary chemical conversion: use a forming solution containing 0.2g / L citric acid and 0.7g / L ammonium dihydrogen phosphate to perform tertiary chemical conversion with a current density of 80mA / cm 2 , voltage 450V, formation time 8min10s, processing temperature 90°C.

[0109] Under the voltage of 450V, under the above-mentioned anodizing conditions, the third-stage forming liquid is clear and transparent, there is no flash fire on the surface of the anode foil, and the edge corrosion of the anode foil is relatively light.

Embodiment 3

[0111] The method of formation is the same as in Example 1, the difference is that the third stage forming liquid:

[0112] Tertiary chemical conversion: use a forming solution containing 0.2g / L citric acid and 0.6g / L ammonium dihydrogen phosphate to perform tertiary chemical conversion with a current density of 80mA / cm 2 , voltage 450V, formation time 8min10s, processing temperature 90°C.

[0113] Under the voltage of 450V, under the above-mentioned anodizing conditions, the third-stage forming liquid is clear and transparent, there is no flash fire on the surface of the anode foil, and the edge of the anode foil is severely corroded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com