Solid electrolyte, lithium metal negative electrode and preparation method thereof

A technology of solid electrolytes and electrolytes, applied in solid electrolytes, composite electrolytes, non-aqueous electrolytes, etc., can solve problems such as complex operations, achieve the effects of increasing diffusion speed, excellent electrochemical performance, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a solid electrolyte, comprising the following steps:

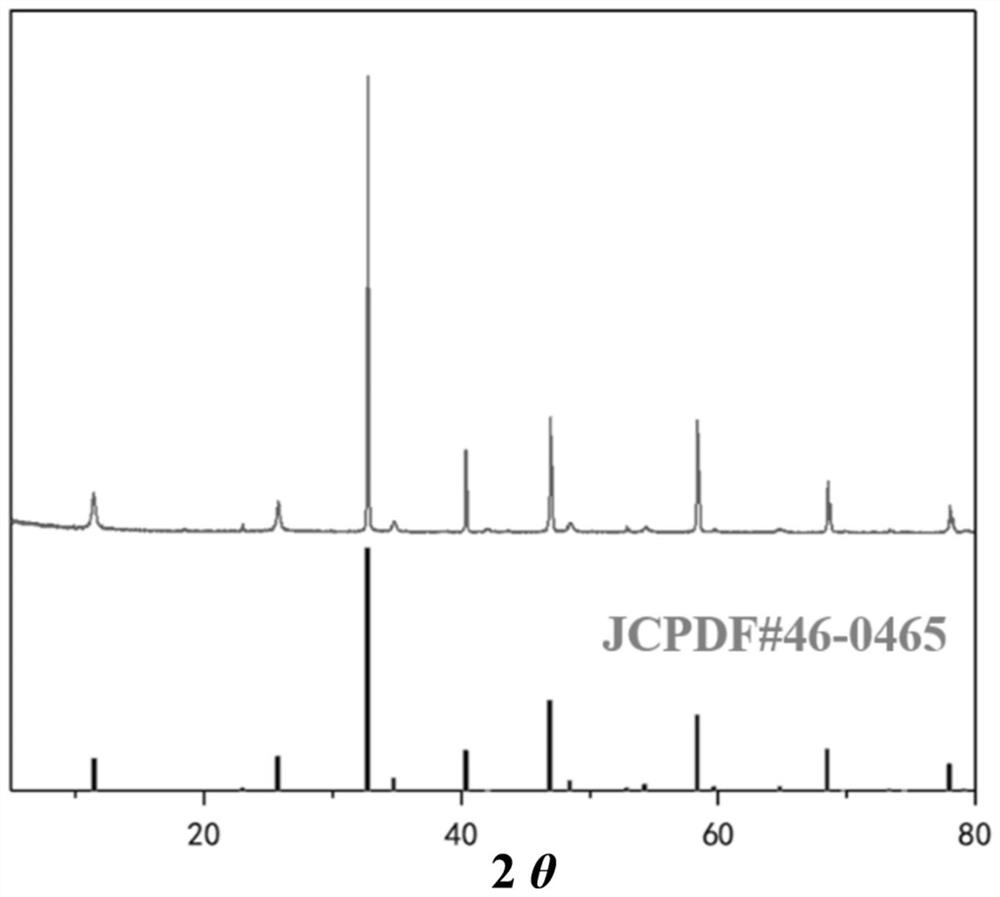

[0037] S1. Preparation of lithium lanthanum titanyl oxide: according to a predetermined ratio, prepare the first reaction system of lithium nitrate, lanthanum nitrate, tetrabutyl titanate and citric acid, and conduct hydrothermal treatment on the first reaction system at 160-200°C Reaction for 8-16 hours; after the hydrothermal reaction is completed, the first reaction product produced by the reaction is dried and pyrolyzed, and then calcined at 800-1000°C for 1-4 hours to prepare lithium lanthanum titanium oxide particles;

[0038] S2, preparation of solid electrolyte: prepare a second reaction system of 2,4-toluene diisocyanate and polypropylene oxide according to a predetermined ratio, and place the lithium lanthanum titanyl oxide particles prepared in step S1 in the second reaction system , stirring at a temperature of 50-80°C for 3-8 hours to react; then pour the se...

Embodiment 1

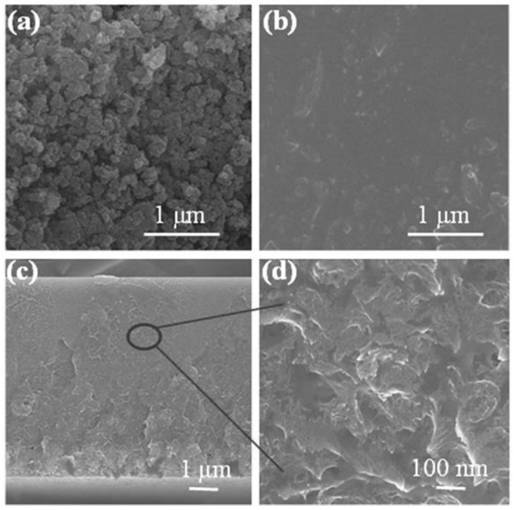

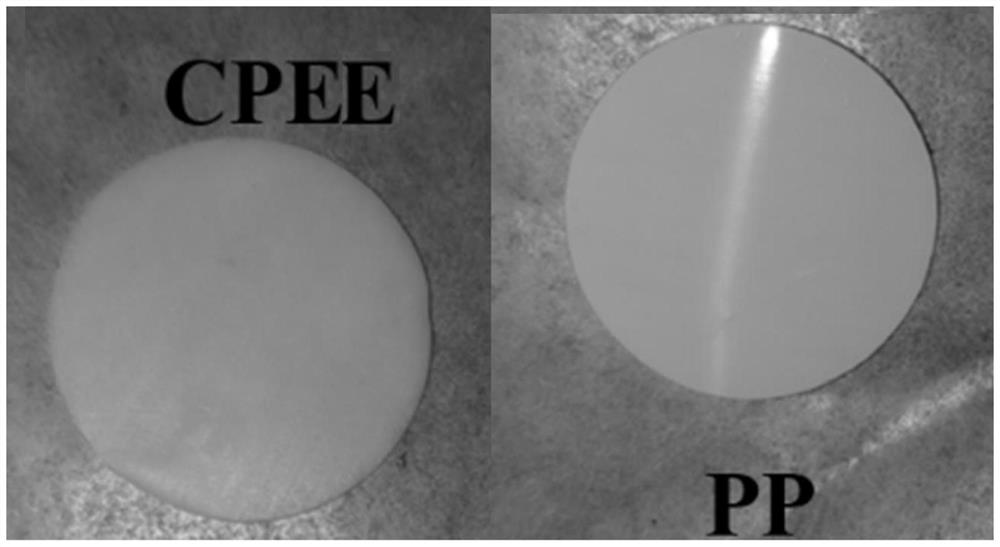

[0053] The preparation of solid LLTO / LPU composite polymer electrolyte (CPPE) comprises the following steps:

[0054] S1, Synthesis of lithium lanthanum titanyl oxide (LLTO) particles:

[0055] 1) Dissolve lithium nitrate, lanthanum nitrate, tetrabutyl titanate and citric acid in absolute ethanol at a molar ratio of 0.33:0.557:1.00:0.887 to obtain lithium nitrate solution, lanthanum nitrate solution, and tetrabutyl titanate Solution and citric acid solution; Wherein, citric acid is used as complexing agent;

[0056] 2) Mix the lithium nitrate solution, the tetrabutyl titanate solution and the citric acid solution evenly to obtain a first mixed solution; then add the lanthanum nitrate solution dropwise under mechanical stirring at 80°C;

[0057] 3) After the lanthanum nitrate solution is added dropwise, stir for 30 minutes to obtain a white suspension and prepare the first reaction system;

[0058] 4) Pour the first reaction system into a 200mL reactor at 180°C, and perform a...

Embodiment 2-3

[0104] The difference from Example 1 is that the mass ratio of lithium lanthanum titanyl oxide particles (LLTO) to linear polyurethane (LPU) is set differently, and the others are the same as in Example 1, and will not be repeated here.

[0105] Table 1 is process parameter setting and its performance parameter in embodiment 1-3

[0106] Example LLTO to LPU mass ratio Ionic conductivity Example 1 1:10 5.0×10 -4 S cm -1

[0107] Combined with Table 1 for analysis: the effect of the mass ratio of lithium lanthanum titanium oxide particles (LLTO) to linear polyurethane (LPU) on the electrochemical performance of solid electrolyte CPPE is: when the mass ratio of LLTO to LPU is set to 1:10, the prepared The solid electrolyte has the highest ionic conductivity and has excellent electrochemical performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com