High-temperature-resistant flame-retardant nylon and preparation method thereof

A flame-retardant nylon and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant flame-retardant nylon and its preparation, can solve problems such as thermal oxygen aging, and achieve the effects of good low warpage, good ductility, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of high temperature flame retardant nylon:

[0031] Specifically, 80 parts of nylon 66, 3 parts of propane trimethylol triacrylate, 4 parts of aluminum stearate, 4 parts of barium stearate, 6 parts of red phosphorus flame retardant, and 5 parts of EVA particles are mixed and put into the twin-screw. Extruder, set host temperature: 250-270°C, host speed: 300-400rpm, feed rate: 600-800rpm, extrude and granulate, put the finished pellets into an oven (100°C) and bake for 3 hours.

[0032] (2) The above-mentioned dried particles were irradiated with cobalt source gamma rays (150kgy), and then dried in an oven at 50°C.

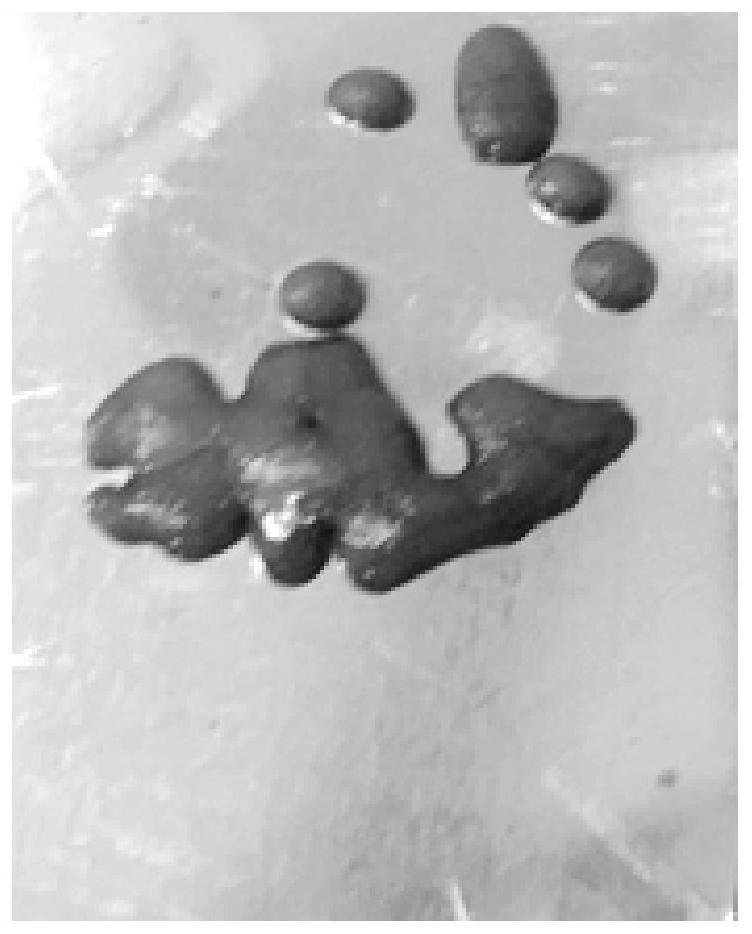

[0033] (3) Put the irradiated high-temperature-resistant flame-retardant nylon, unirradiated nylon particles and untreated nylon particles into the muffle furnace (280°C) at the same time, observe and compare the temperature resistance conditions, and the results show that At figure 1 .

Embodiment 2

[0035] (1) Preparation of high temperature flame retardant nylon:

[0036] Specifically, 90 parts of nylon 6, 5 parts of propane trimethylol triacrylate, 6 parts of barium stearate, 2 parts of nano-zirconium phosphate, 10 parts of red phosphorus flame retardant, and 6 parts of EVA particles were mixed and put into twin-screw extrusion. Out of the machine, set the host temperature: 250-270°C, the host speed: 300-400rpm, the feeding rate: 600-800rpm, extrude and granulate, put the granules into the oven (100°C) and bake for 3 hours.

[0037] (2) The above-mentioned dried particles were irradiated with cobalt source gamma rays (150kgy), and then dried in an oven at 50°C.

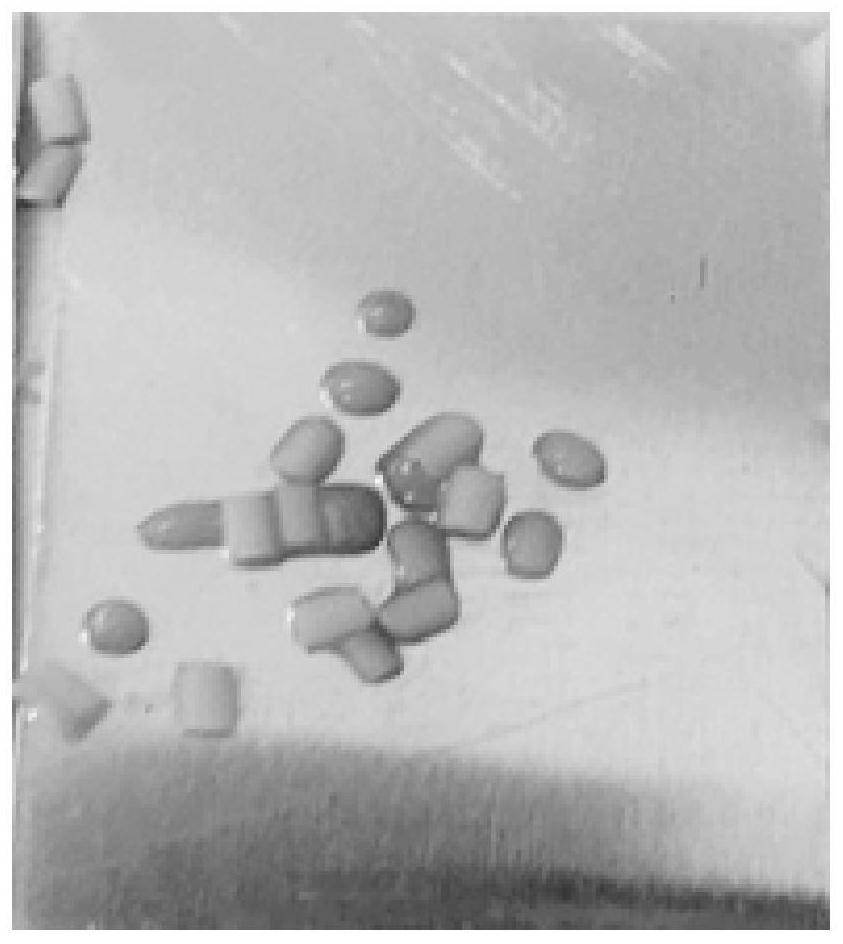

[0038] (3) The above-mentioned irradiated cross-linked nylon particles, unirradiated nylon particles and untreated nylon particles were tested for melt index and injection molded into 0.7mm flame retardant samples. The flame retardant performance was tested by UL94 flame retardant standard. Properties are show...

Embodiment 3

[0040] (1) Preparation of high temperature flame retardant nylon:

[0041] Specifically, 90 parts of nylon 6, 5 parts of trimethylolpropane trimethacrylate, 4 parts of zinc calcium stabilizer, 4 parts of hydrotalcite, 10 parts of red phosphorus flame retardant, and 6 parts of EVA particles are mixed and put into Twin-screw extruder, set the host temperature: 250-270°C, host speed: 300-400rpm, feed rate: 600-800rpm, extrude and granulate, put the prepared pellets into the oven (100°C) and bake for 3 hours .

[0042] (2) The above-mentioned dried particles were irradiated with cobalt source gamma rays (150kgy), and then dried in an oven at 50°C.

[0043] (3) Inject the above-mentioned irradiated cross-linked nylon particles and unirradiated nylon particles into a 0.7mm flame retardant sample, and use the UL94 flame retardant standard to test the flame retardant properties. The flame retardant properties are shown in Table 1. The melt index Data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com