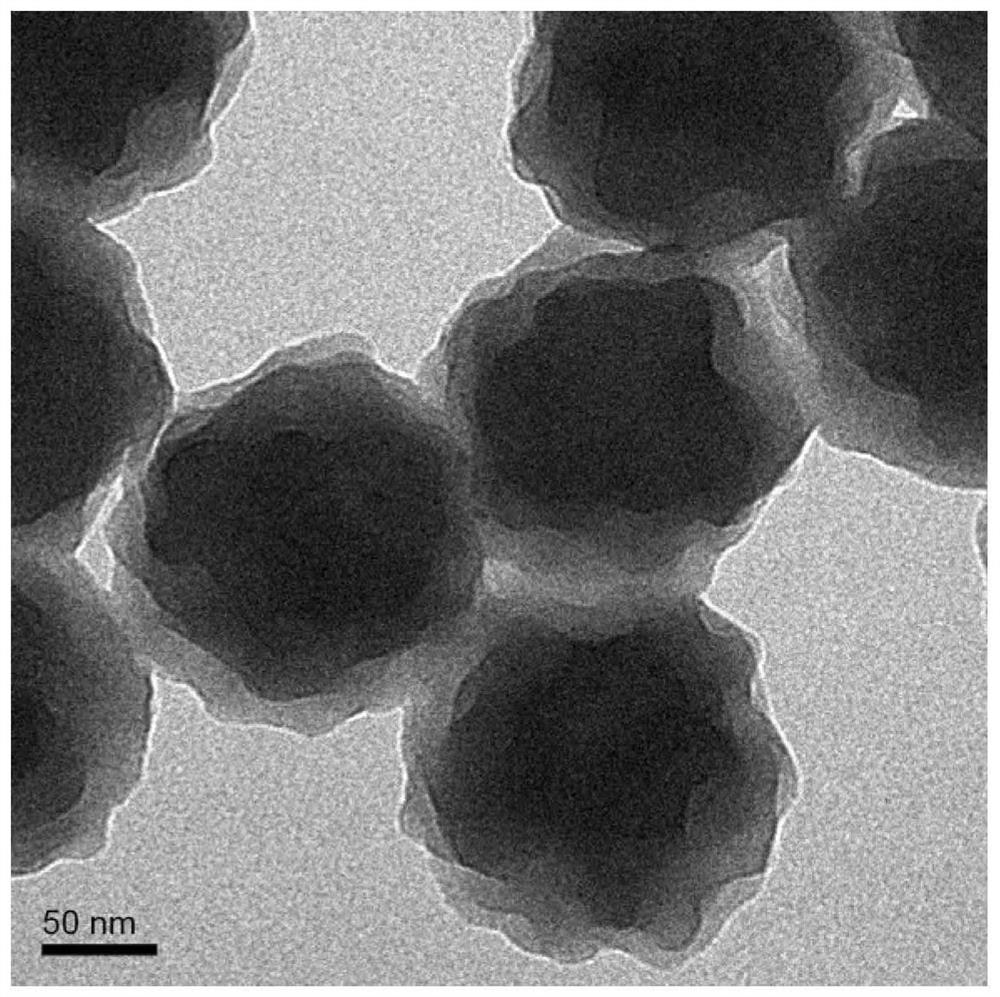

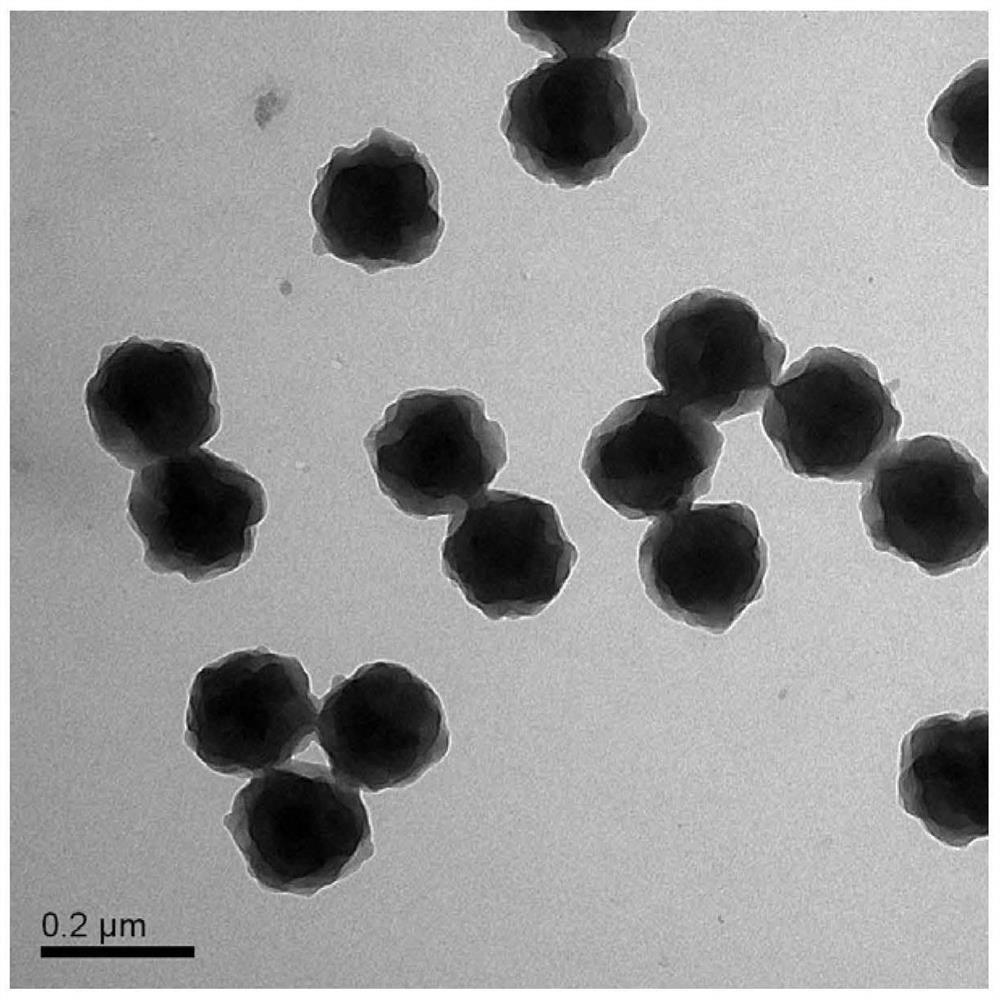

Preparation method and application of antireflection coating liquid containing raspberry-shaped hierarchical structure latex particles

An anti-reflection coating and hierarchical structure technology, applied in textiles and papermaking, can solve the problems of obvious anti-reflection effect, heat-resistant textile finishing, reducing the reflectivity of substrates, etc., and achieve easy large-scale industrial production and finishing processes. Simple and easy to implement, the effect of reaction conditions is not harsh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Weigh 0.03g of γ-methacryloxypropyltrimethoxysilane and add it to 84.76g of water. After mixing evenly with mechanical stirring, add 10g of methyl methacrylate and 1g of divinylbenzene, mechanically After stirring evenly, put it into a water bath, turn on N 2 After 15 minutes, the temperature was raised to 70°C and kept for 3 hours; after that, 0.08g of potassium persulfate was dissolved in 5g of water and added to the reaction mixture. After 8 hours of reaction, a latex product 1 with a "raspberry-like" hierarchical structure was obtained. The solid content is 11%.

[0050] (2) Weigh 1g of sodium dodecylbenzene sulfonate and add it to 83.94g of water. After mechanical stirring and mixing, add 10g of butyl acrylate to the solution. After mechanical stirring, put it into a water bath to pass N 2 15min, after heating up to 70°C, dissolve 0.06g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 2.5h, raise the temperatu...

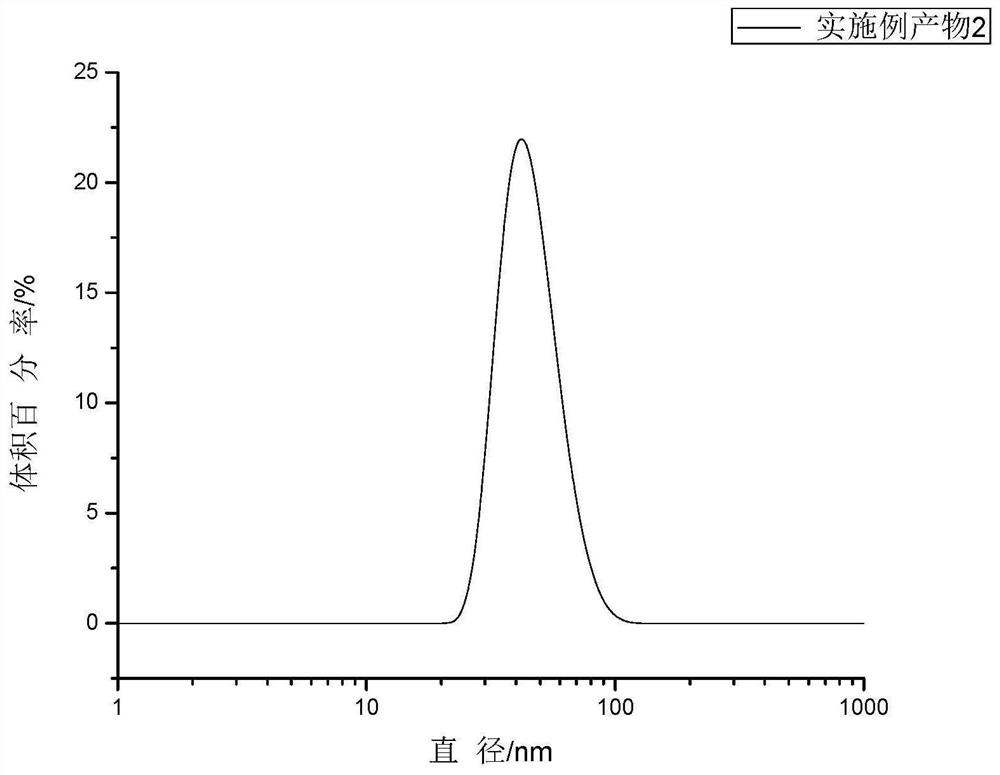

Embodiment 2

[0055] (1) Weigh 0.7g of vinyltriethoxysilane and add it to 74.78g of water. After mechanically stirring and mixing uniformly, add 7.5g of styrene and 0.13g of allyl methacrylate to the solution. After mechanically stirring uniformly, Put into the water bath and pass N 2 After 15 minutes, the temperature was raised to 85° C., and after 3 hours of reaction, 0.06 g of potassium persulfate was dissolved in 5 g of water and added to the above reaction mixture, and the reaction was continued for 8 hours to obtain a latex product 3 with a “raspberry-like” hierarchical structure. The solid content is 10%.

[0056] (2) Weigh 2g of sodium lauryl sulfate and add it to 72.94g of water. After mechanical stirring and mixing, add 20g of isooctyl acrylate to the solution. After mechanical stirring, put it into a water bath to pass N 2 15min, after heating up to 75°C, dissolve 0.06g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 2.5h, rais...

Embodiment 3

[0058] (1) Weigh 0.06g of sodium lauryl sulfate and 0.14g of isooctylphenyl glycoside and add them to 69.88g of water. After mechanically stirring and mixing evenly, add 1.3g of vinyl tri(methoxy)ethyl alcohol to the solution successively. Oxysilane, 8g of isobornyl acrylate and 0.7g of ethylene glycol dimethacrylate, after mechanical stirring, put into a water bath and pass N 2 15min, heat up to 80°C, and keep warm for 2.5h; then dissolve 0.08g of potassium persulfate in 5g of water and add it to the above reaction mixture, and continue the reaction for 9h to obtain a latex product with a "raspberry-like" hierarchical structure 5 , with a solid content of 12.5%.

[0059] (2) Weigh 0.2g of sodium lauryl sulfate and add it to 69.72g of water. After mechanical stirring and mixing, add 25g of butyl acrylate to the solution. After mechanical stirring, put it into a water bath to pass N 2 15min, after heating up to 80°C, dissolve 0.08g of ammonium persulfate in 5g of water and add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com