High-nitrogen biochar composite material as well as preparation method and application thereof

A composite material, biochar technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, carbon compounds, etc., can solve problems such as low energy density, reduce system reaction temperature and increase nitrogen content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

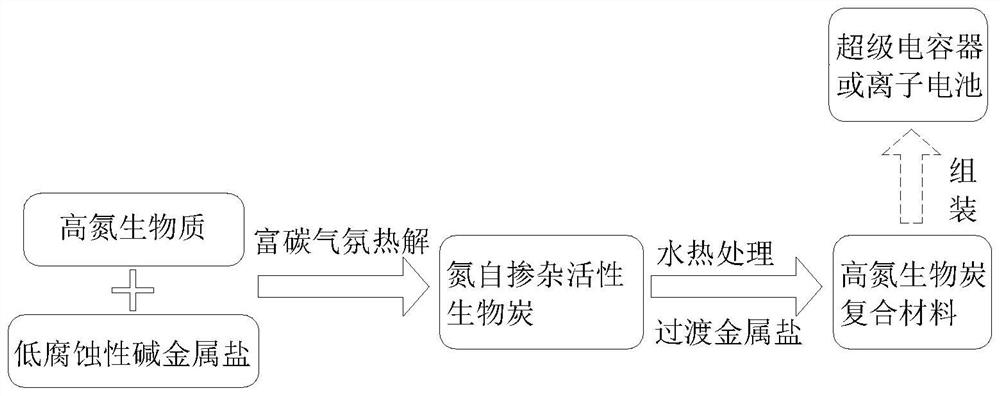

Method used

Image

Examples

Embodiment 1

[0044] Utilize high-nitrogen biochar composites to prepare supercapacitor electrodes, comprising the following steps:

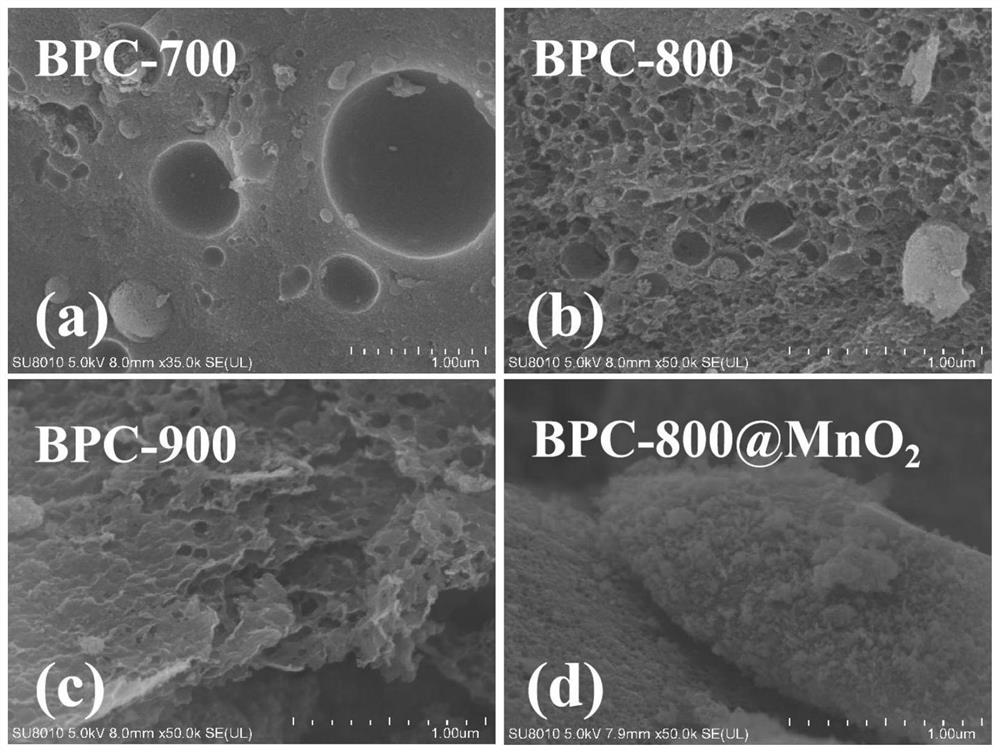

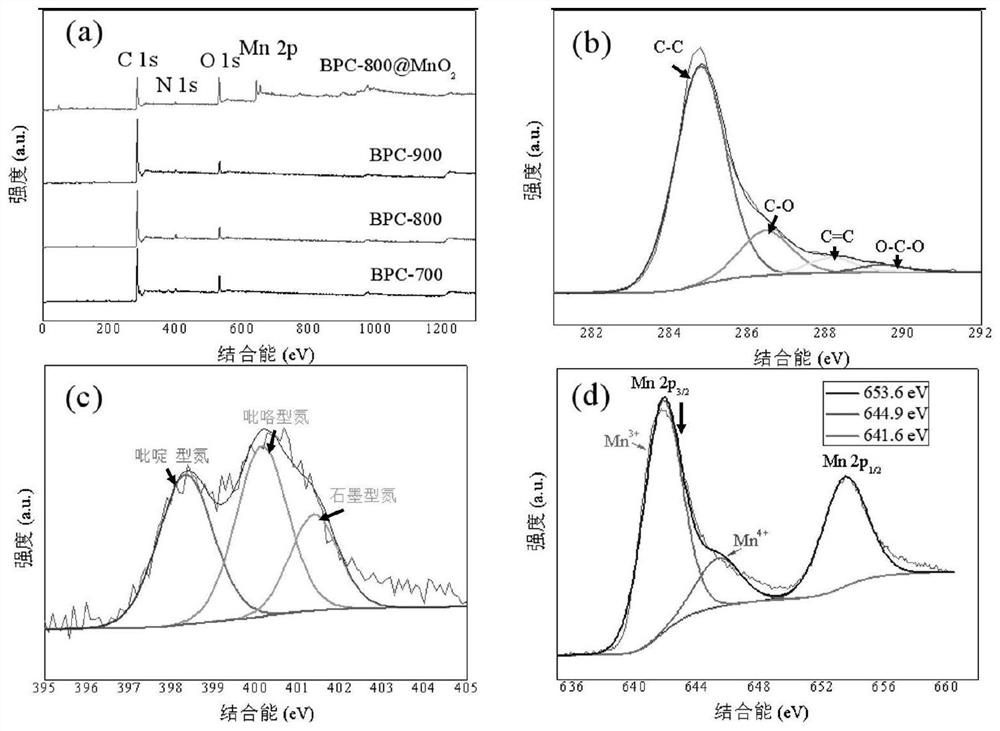

[0045] Step 1: Weigh a certain quality of bean cake dregs raw material, mix with 2 M hydrochloric acid, heat to 60°C, carry out magnetic stirring and repeated pickling for 8 h, filter, then rinse with distilled water until the filtrate is neutral, and obtain solid phase washed bean cake dregs . After drying, take 5 g solid-phase washed bean cake dregs samples and place them in a tube furnace, and put 20% volume fraction CO 2 The gas was premixed with Ar gas as a carrier gas and passed into the tube furnace. After stabilization, the tube furnace was heated from room temperature to 800 °C for 2 h. After the sample was naturally cooled, it was taken out to prepare nitrogen self-doped active bean cake. Slag carbon, recorded as BPC-800-20%;

[0046] Step 2: Mix nitrogen self-doping active bean cake residue carbon BPC-800-20%, acetylene black and polytetrafluoroe...

Embodiment 2

[0050] A certain quality of bean cake dregs was weighed, mixed with 2 M hydrochloric acid, heated to 60°C for repeated pickling with magnetic stirring, filtered, and then rinsed with distilled water until the filtrate was neutral to obtain solid-phase washed bean cake dregs. Take 5g sample of solid-phase washed bean cake dregs and place it in a tube furnace, and put 100% volume fraction CO 2 The gas was used as the carrier gas and passed into the tube furnace. After stabilization, the tube furnace was heated from room temperature to 800 °C for 2 h. After the sample was naturally cooled, it was taken out to obtain activated bean cake residue carbon, which was designated as BPC-800;

[0051]Mix active bean cake residue carbon BPC-800, acetylene black and polytetrafluoroethylene at a mass ratio of 8:1:1, add an appropriate amount of isopropanol and grind to make an electrode film, and dry the electrode film in a vacuum oven at 80°C for 8 h, then cut a certain 1 cm × 1 cm diaphrag...

Embodiment 3

[0058] A certain quality of bean cake dregs was weighed, mixed with 2 M hydrochloric acid, heated to 60°C for repeated pickling with magnetic stirring, filtered, and then rinsed with distilled water until the filtrate was neutral to obtain solid-phase washed bean cake dregs. Weigh 0.025g of potassium carbonate and dissolve it in deionized water, add 5g of dried solid-phase washed bean cake dregs, and keep magnetic stirring at 70°C until the two are fully mixed. The mixture was placed in a tube furnace with 100% volume fraction of CO 2 The gas was used as carrier gas and passed into the tube furnace. After stabilization, the tube furnace was heated from room temperature to 700 °C for 0.5 h. After the sample was naturally cooled, it was taken out to prepare chain-type activated bean cake residue charcoal, and its specific surface area was measured. 678 m 2 / g, the nitrogen content is 5.2 wt.%.

[0059] From the above test results, it can be seen that in CO 2 A small amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com