A kind of preparation method of nonthion phosphorus oil-soluble organic molybdenum additive

A technology of non-thion phosphorus oil and organic molybdenum, which is applied in the field of preparation of non-thion phosphorus oil-soluble organic molybdenum additives, can solve problems such as cumbersome process, and achieve the effects of simplifying the reaction path, reducing reaction loss, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

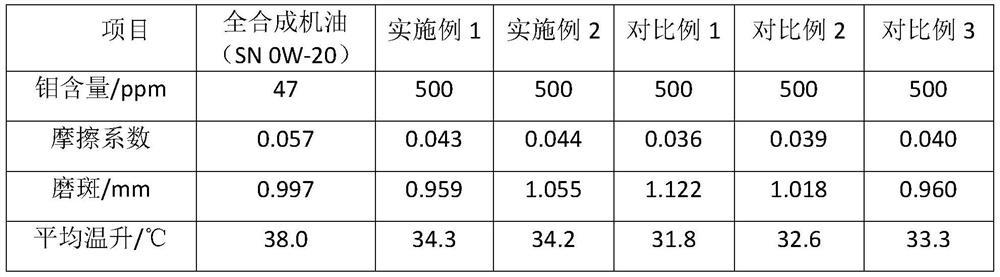

Embodiment 1

[0029] (1) One-step preparation of soybean oil amide

[0030] Add 47.5g of soybean oil to a 250mL three-necked flask with a condenser and a thermometer, heat the three-necked flask to about 110°C to 120°C in an oil bath, add 15g of hydroxyethylethylenediamine dropwise to the reaction system, and Continue mechanical stirring for 3h. Turn off the heating after the reaction, and collect it for later use after the temperature drops to room temperature to obtain soybean oil amide.

[0031] (2) One-step preparation of non-sulfur phosphorus oil-soluble organic molybdenum additives from soybean oil amides

[0032] Add the soybean oil amide obtained in step 1 into a 250 mL three-necked flask, add 10 mL of petroleum ether, start heating and stirring, and control the heating temperature at 100°C to 110°C. Without stopping stirring, 46 g of 18 wt.% ammonium molybdate aqueous solution was added dropwise to the reaction system using a constant pressure titration funnel, and refluxed at 10...

Embodiment 2

[0034] (1) One-step preparation of soybean oil amide

[0035] Add 47.5g of soybean oil to a 250mL three-necked flask with a condenser and a thermometer, heat the three-necked flask to about 110-120°C in an oil bath, add 15g of hydroxyethylethylenediamine dropwise to the reaction system and continue at this temperature Stir mechanically for 3h. Turn off the heating after the reaction, and collect it for later use after the temperature drops to room temperature to obtain soybean oil amide.

[0036] (2) One-step preparation of non-sulfur phosphorus oil-soluble organic molybdenum additives from soybean oil amides

[0037] Add the soybean oil amide obtained in step 1 into a 250mL three-neck flask, add 10mL of petroleum ether, start heating and stirring, and control the heating temperature at 100-110°C. Without stopping stirring, 34 g of 18 wt.% ammonium molybdate aqueous solution was added dropwise to the reaction system using a constant pressure titration funnel, and refluxed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com