Preparation method of composite fiber membrane for improving loading stability of silver nanoparticles

A composite fiber membrane and silver nanoparticle technology, applied in the field of materials, can solve the problems of high silver particle agglomeration and shedding rate, which limit the application of silver nanocomposites, and achieve controllable shape, high axial strength, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

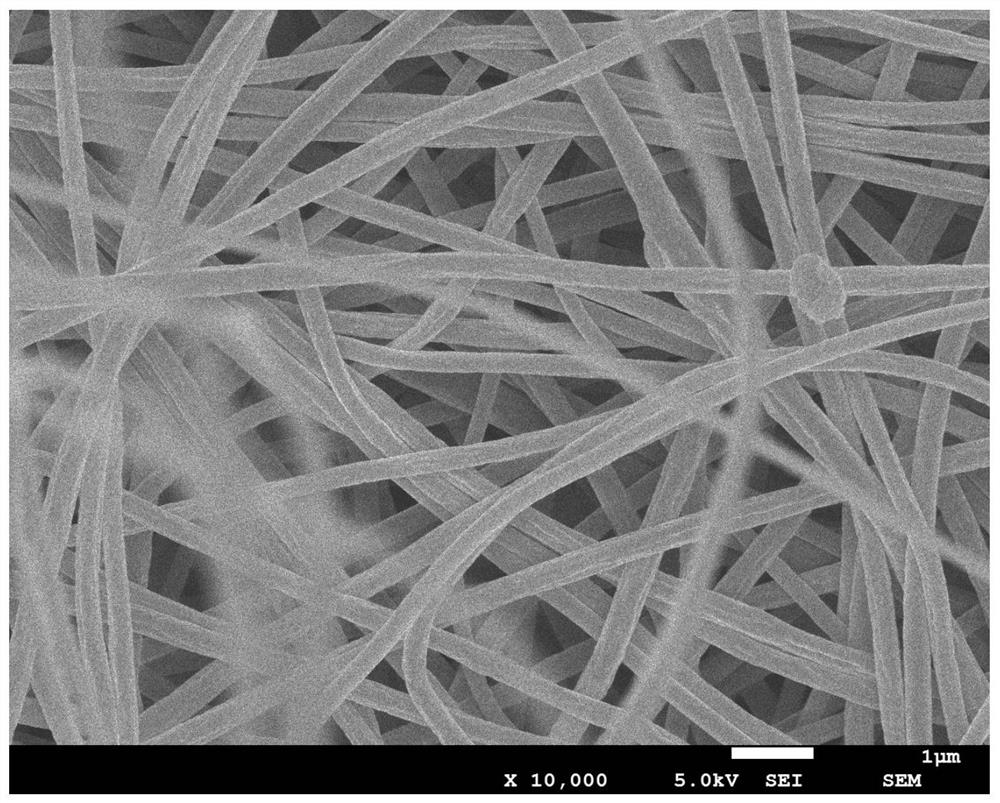

[0034] Embodiment 1: as figure 1 , 4 As shown in -6, the present invention provides a technical solution, the preparation of mercapto-functionalized graphene oxide: add 0.1gPAN in 10mlDMF, magnetically stir for 30min until PAN dissolves, ultrasonically disperse 0.02g graphene oxide, and the ultrasonic time is 30min;

[0035] Add 0.0224g of cysteamine hydrochloride to dissolve it ultrasonically, add 0.0012g of DMAP, and finally add 0.0398g of DCC after dissolving, and carry out esterification reaction at room temperature for 4 hours with low-speed magnetic stirring;

[0036] According to the above-mentioned technical scheme, DMF is in anhydrous state, and is stirred by a glass rod during ultrasonic dispersion, and is operated under an ice bath state.

[0037] According to the above technical solution, the DMAP ratio is nCH / nDMAP=2:1, and the DCC ratio is nCH / nDCC=1:6.18.

[0038] After the reaction is completed, the liquid is suction-filtered, and the filtrate is washed with ...

Embodiment 2

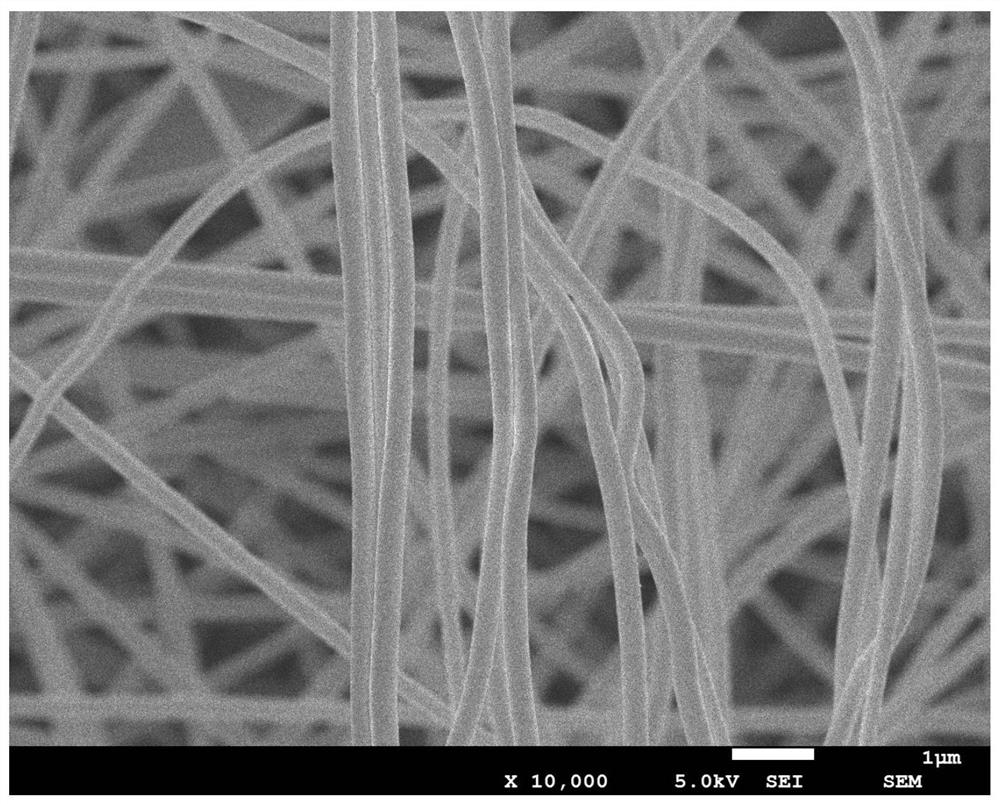

[0045] Embodiment 2: as figure 2 As shown, the preparation of AgNPs@PAN by in situ reduction method: First, disperse 0.1g PVP in 10gDMF with magnetic stirring, add 0.02gAgNO3, put the mixed solution in an oil bath at 60°C for 6h, and then pour it into the obtained orange solution Add 1g of PAN (10wt%) and magnetically stir for 24 hours at room temperature to obtain a uniform and stable precursor solution;

[0046] The electrospinning parameters are controlled as follows: the injector push speed is maintained at 0.48ml / h, the distance from the needle to the collector is 20cm, the voltage is 21kv, the inner diameter of the stainless steel needle is 0.6mm, the ambient temperature and relative humidity are 25±2°C and 40± 5%, dried in a vacuum oven at 60°C for 6h.

[0047] The AgNPs@PAN nanofiber membrane prepared by in situ reduction method was characterized as follows: figure 2 .

[0048] The above 20*20mm2 membrane material was subjected to a stability test at different pH,...

Embodiment 3

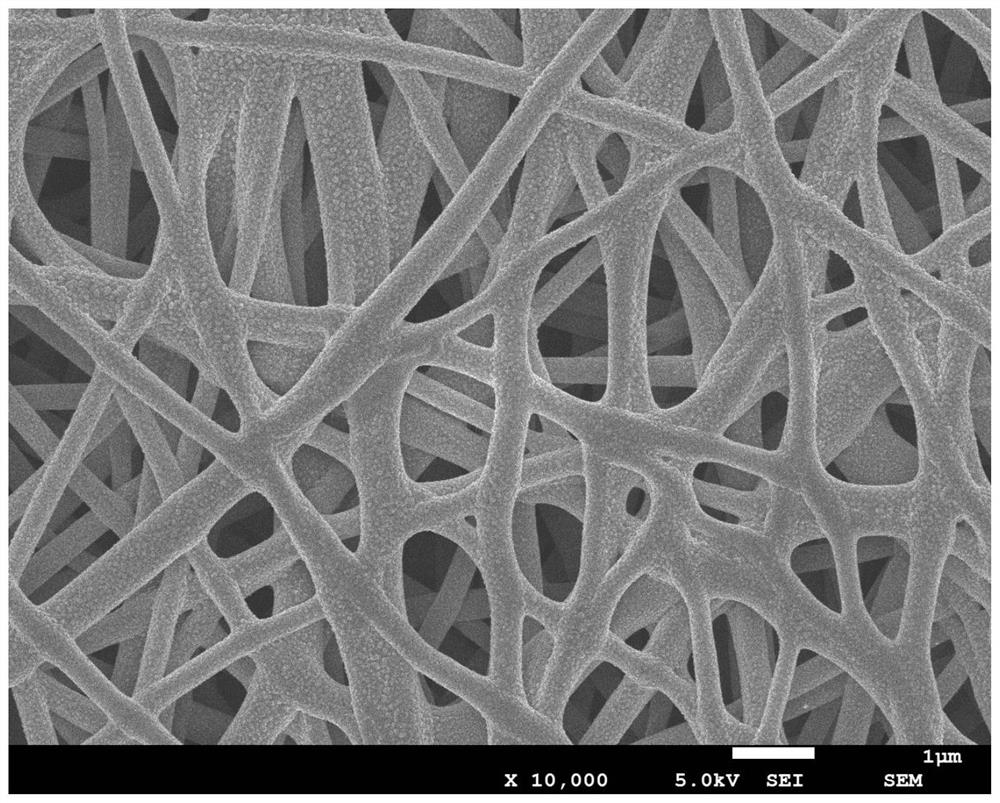

[0050]Example 3: Preparation of AgNPs@PAN by ultraviolet reduction method: disperse 1gPAN in 10gDMF, stir magnetically for 24h, and obtain a homogeneous PAN solution with a concentration of 10wt%;

[0051] The electrospinning parameters are controlled as follows: the injector push speed is maintained at 0.72ml / h, the distance from the needle to the collector is 18cm, the voltage is 21kv, the inner diameter of the stainless steel needle is 0.67mm, and the ambient temperature and relative humidity are 25±2°C and 40± 5%.

[0052] After spinning, cut the membrane into 20*20mm2, soak it in AgNO3 (2wt%) solution for 24 hours, take it out, wash it with ultrapure water for 2-3 times, and dry it in a freeze dryer for 24 hours. After drying, take out the film, spread it on a sterile black plastic bag, and restore it by UV sterilizing lamp irradiation. Finally, the membrane was washed 2-3 times, and dried in a vacuum oven at 60° C. for 6 hours.

[0053] The AgNPs@PAN nanofiber membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com