Photonic crystal sensing material for SEB ultra-sensitive detection, preparation method thereof and method for ultra-sensitive detection of SEB

A technology of photonic crystals and sensing materials, which is applied in the direction of material analysis, analysis materials, and measuring devices through optical means, can solve the problems of complicated operation procedures, long time required for the detection process, and inability to meet fast and convenient detection, etc., to achieve Convenient operation, improved biocompatibility, and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

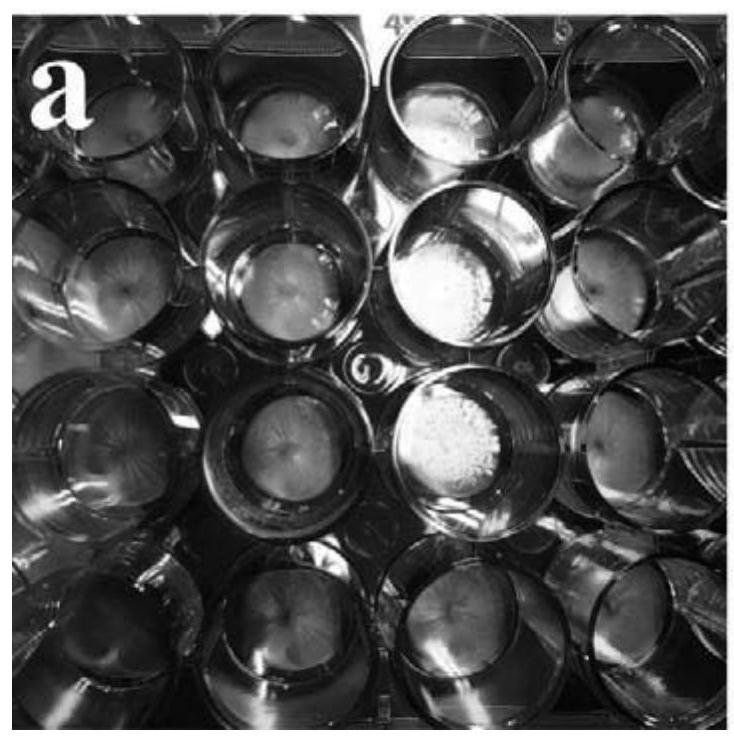

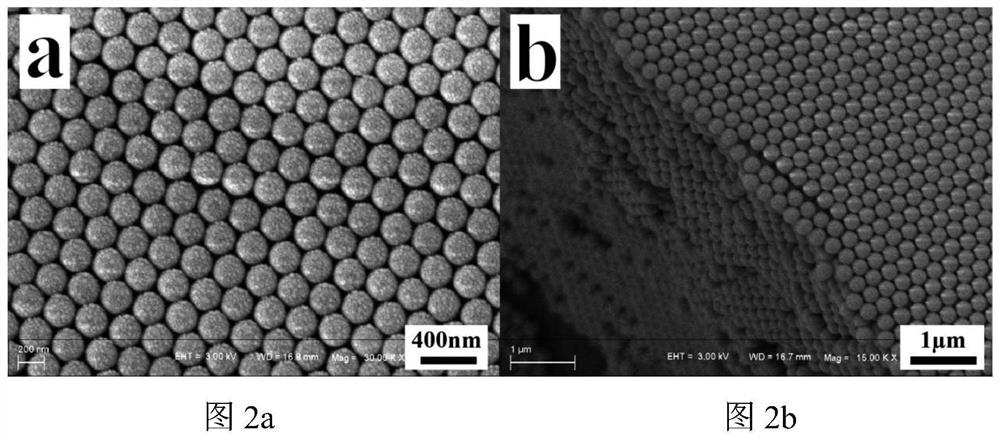

[0035] Preparation of Photonic Crystal Sensing Materials

[0036] (1) Add 150 mL of absolute ethanol and 9 mL of ammonia water to the washed dry flask and mix, then add 7.2 mL of tetraethyl orthosilicate (TEOS), stir vigorously at 30°C, and react at 600 rpm for 9 hours; After the end, the remaining ammonia water and dehydrated alcohol are removed by centrifugal method (rotating speed 4000rpm), then redispersed in dehydrated alcohol, and the particle size is separated by centrifugal sieving (800rpm to get supernatant, 1500rpm to get precipitation), and finally the obtained The colloidal particles (silicon spheres) were dispersed in 10 mL of absolute ethanol and stored;

[0037] (2) Take 1 mL of the synthesized silicon ball and dilute it to 10 mL with absolute ethanol, place it in a 50 mL flask, add 200 μL of 3-aminopropyltriethoxysilane (APTES) and sonicate for 5 min, then fill with nitrogen and remove oxygen 30min, and finally mechanically stirred for 6 hours at 70°C. After t...

Embodiment 2

[0042] Check the drawing of the working curve

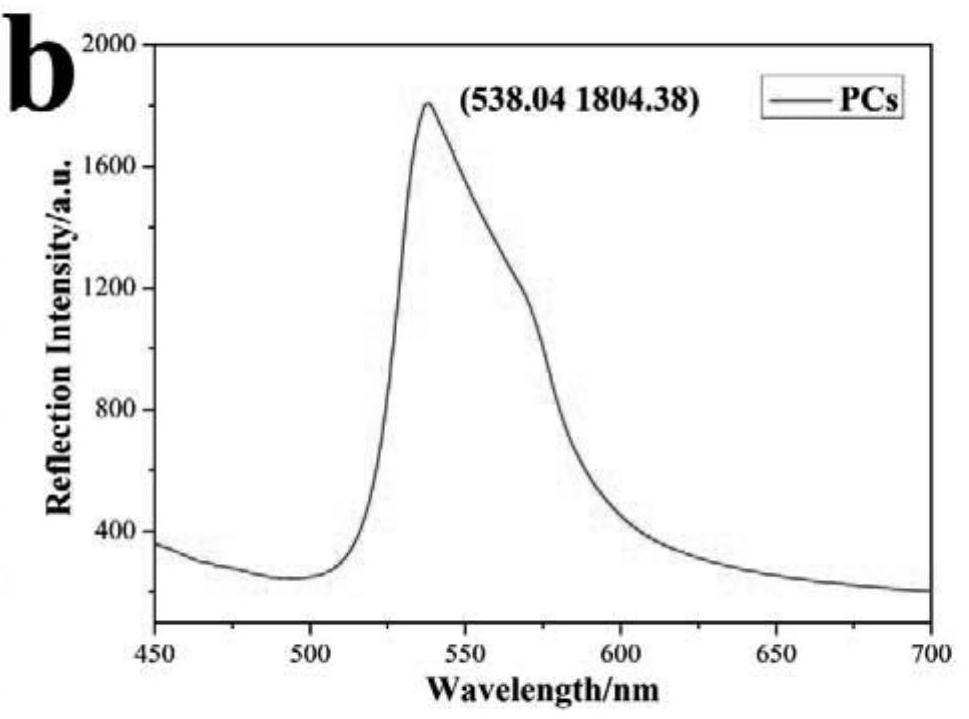

[0043] (1) Soak the photonic crystal sensing material in PBS buffer (pH is 7.4), fix the probe of the optical fiber spectrometer vertically above the photonic crystal and immerse it under the liquid surface, and obtain the reflection spectrum of the photonic crystal;

[0044] (2) After the system is stabilized, SEB with different concentrations is added in sequence, so that the SEB concentration of the system becomes 0.01 fg / mL ~ 1 μg / mL, and the stabilized reflection peaks are recorded respectively;

[0045] (3) Taking the logarithm of SEB concentration as the abscissa, and the variation of the reflection peak intensity as the ordinate, establish a working curve. like Figures 3a-3c shown, Figure 3a The response of the Aptamer-PC sensing material to SEB is shown; Figure 3b The relationship between the logarithm of SEB concentration and the change in reflection peak intensity is shown; Figure 3c A standard curve for detect...

Embodiment 3

[0047] (1) Milk sample, centrifuged at 8000rpm for 15 minutes to remove fat, and then diluted 500 times with PBS buffer;

[0048] (2) Add different concentrations of SEB standards to the above-mentioned treated samples respectively, to make them spiked samples of different concentrations (0.1pg / mL, 1pg / mL and 100pg / mL);

[0049] (3) The above-mentioned spiked samples are sequentially added to the sensing system, and after stabilization, the intensity change of the reflection peak is recorded, and the spiked recovery rate is calculated. The results are shown in Table 1 below:

[0050] Table 1 Detection results of SEB in milk samples

[0051]

[0052] Note: N.D.* means SEB not detected.

[0053] It can be seen from the results in Table 1 that the recovery rate of standard addition of the milk sample is 100.63% to 114.98%, indicating that the method of the present invention has better accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com