Hollow iron-nickel nitride catalyst, preparation method and all-water electrolysis application thereof

A technology of nitrides and catalysts, applied in the field of hollow iron-nickel nitride catalysts and preparations, can solve the problems of reducing the utilization rate of catalyst materials, catalytic activity, affecting the full exposure of active sites, and easy agglomeration of nanostructures, which is beneficial to batch preparation , low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

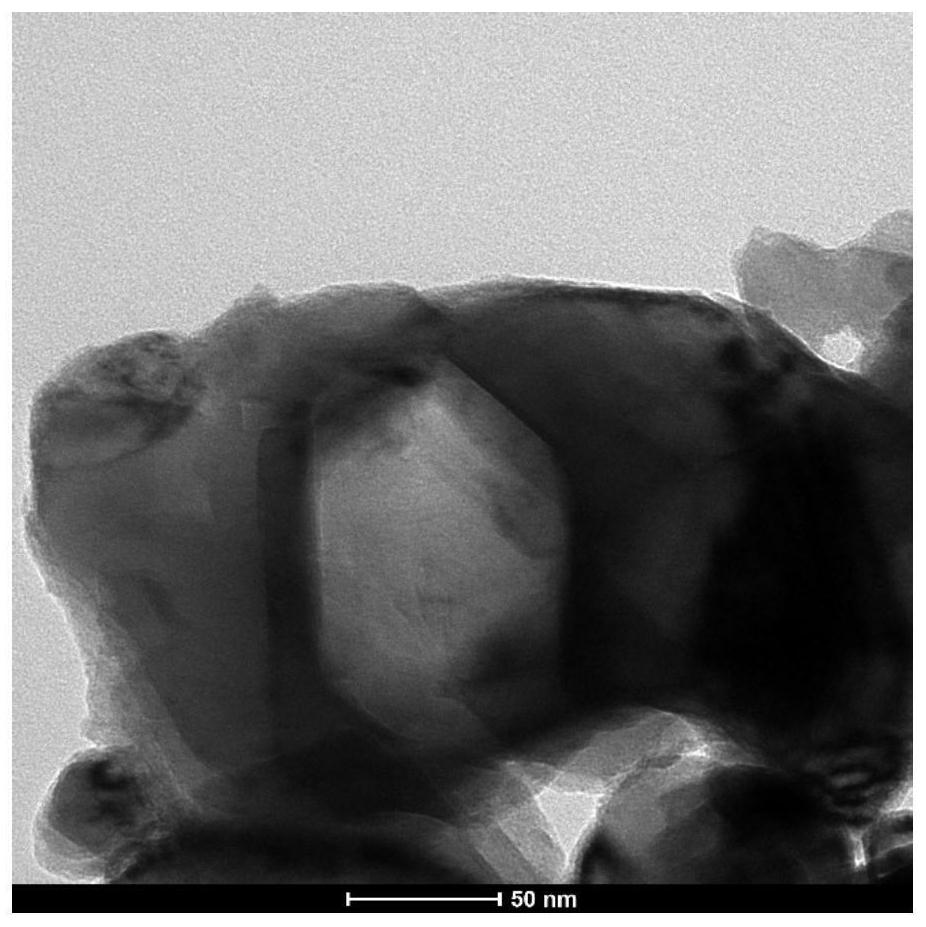

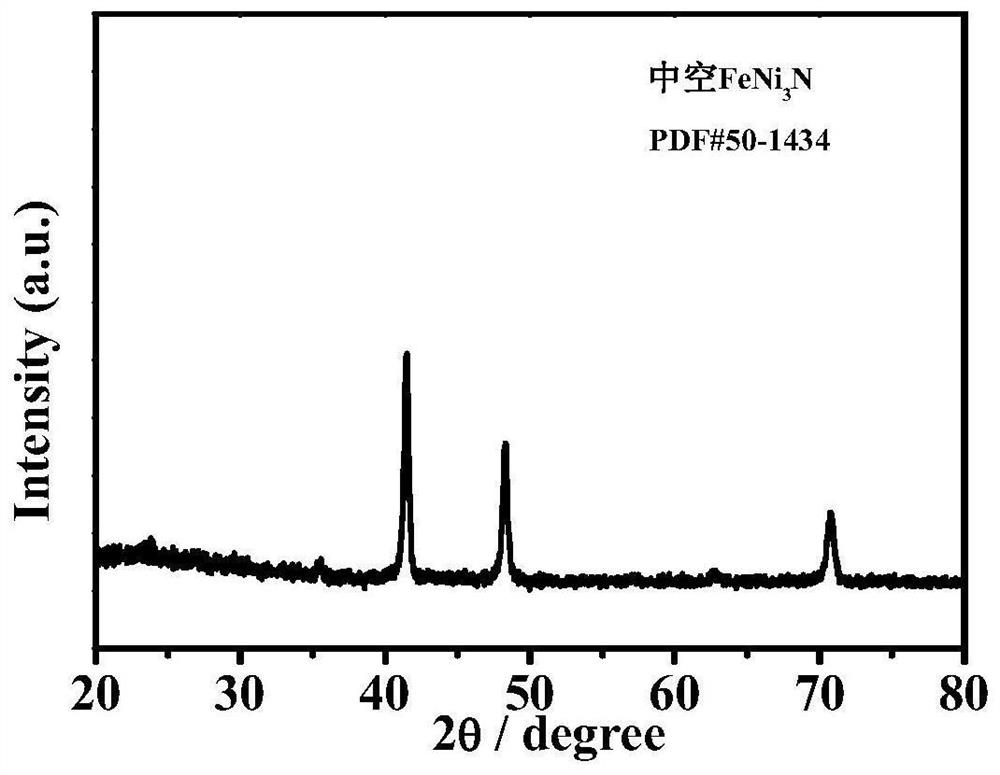

[0031]Preparation of hollow iron-nickel nitride catalyst: select granular 100-300 nm iron-nickel alloy nanoparticles, in which the atomic ratio of iron and nickel is 1:3, place them in an air atmosphere, heat to 400°C, and hold for 2 hours. Hollow iron-nickel alloy nanoparticles are obtained, and the hollow iron-nickel alloy nanoparticles are further placed in an ammonia atmosphere and kept at 500°C for 3 hours to obtain hollow iron-nickel nitride nanoparticles (FeNi3N) Catalyst. For its morphological structure and crystal structure, seefigure 1 withfigure 2 .

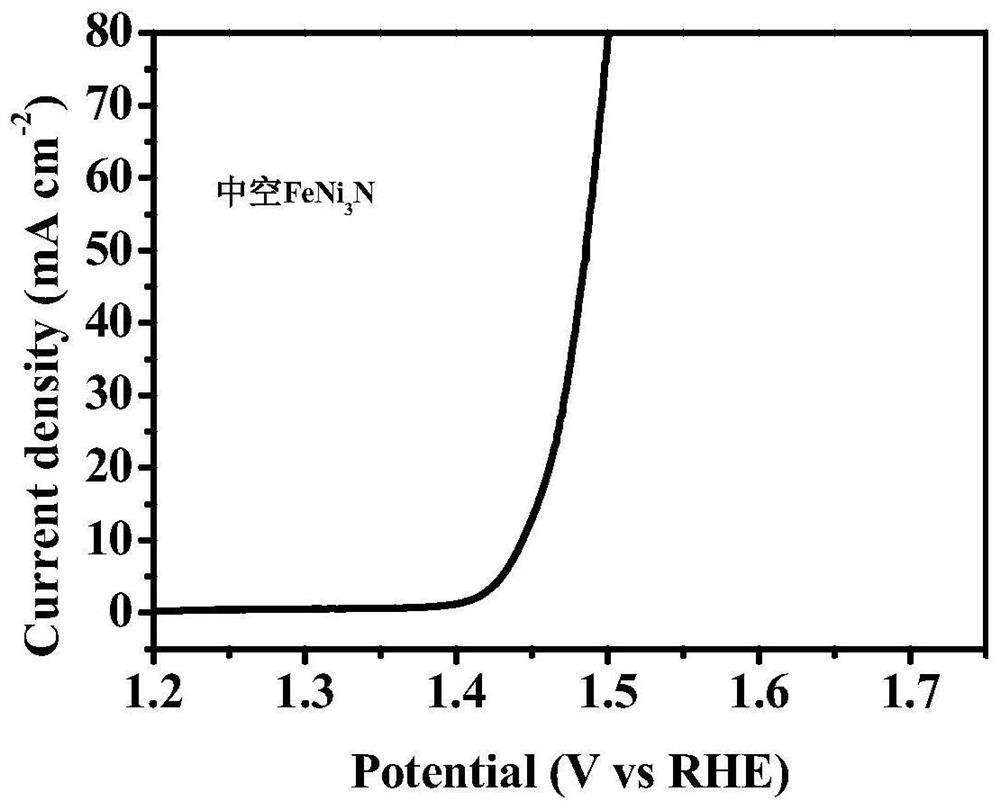

[0032]The hollow iron-nickel nitride nanoparticles obtained in Example 1 (FeNi3N) The catalyst is used in the hydroelectric analysis of oxygen and hydrogen evolution reactions. The specific process is: take 5 mg of catalyst and disperse in 1 ml of ethanol and 50 μl of Nafion solution to make a well-dispersed catalyst ink, and drop it on the surface of the glassy carbon electrode Add 5 μl of catalyst ink and use it for hydroelec...

Embodiment 2

[0034]Preparation of hollow iron-nickel nitride nanoparticles: select granular 100-300 nm iron-nickel alloy nanoparticles, in which the atomic ratio of iron and nickel is 1:3, place them in an air atmosphere, heat to 450°C, and hold for 2 hours , To obtain hollow iron-nickel alloy nanoparticles. Furthermore, the hollow iron-nickel alloy nanoparticles were placed in an ammonia atmosphere and kept at 450°C for 3 hours to obtain hollow iron-nickel nitride nanoparticles (FeNi3N) Catalyst.

Embodiment 3

[0036]Preparation of hollow iron-nickel nitride nanoparticles: select granular 100-300 nm iron-nickel alloy nanoparticles, in which the atomic ratio of iron and nickel is 1:3, place them in an air atmosphere, heat to 400°C, and hold for 2 hours , To obtain hollow iron-nickel alloy nanoparticles. Furthermore, the hollow iron-nickel alloy nanoparticles were placed in an ammonia atmosphere and kept at 400°C for 3 hours to obtain hollow iron-nickel nitride nanoparticles (FeNi3N) Catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com