Production system, preparation method and components of toothpaste-grade sodium monofluorophosphate

A sodium monofluorophosphate, production system technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as unsterilized sodium monofluorophosphate, harmful waste gas, harmful impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

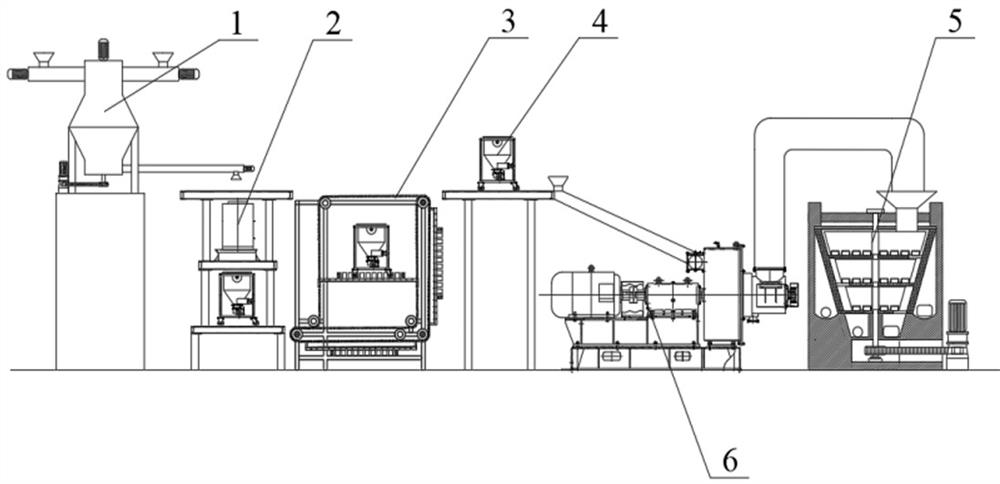

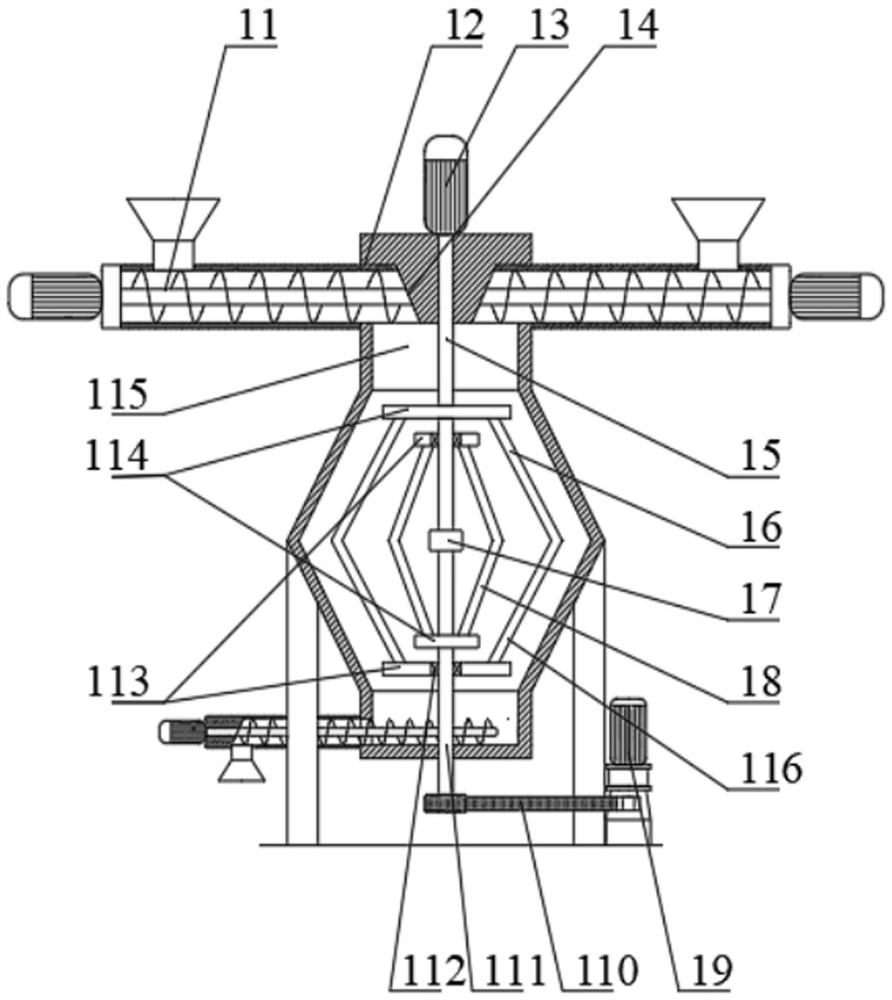

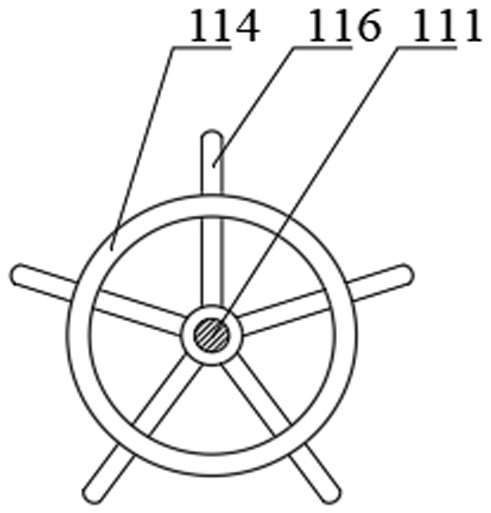

[0085] A production system for sodium monofluorophosphate, the production system includes a raw material mixing and deployment device 1, a melting reaction furnace 2, a cooler, a pulverizer, a particle size control device 5, a packaging machine, and a transfer bin 4 for transferring materials on a production line and the transfer bin hoist 3, wherein the feed end of the raw material mixing and dispensing device is used to put sodium hexametaphosphate, sodium fluoride and phosphorus pentoxide in different parts by weight and fully mix the three, and the outlet of the raw material mixing and distributing device T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com