Printing method for improving color fastness to light of natural dye cotinus coggygria pigment

A technology of cotinus pigment and natural dye, applied in the field of plant dyeing, can solve the problems of poor color fastness to light, poor printing and dyeing effect, poor dyeing rate, etc., achieve good compatibility, improve color fastness, and reduce light fading degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

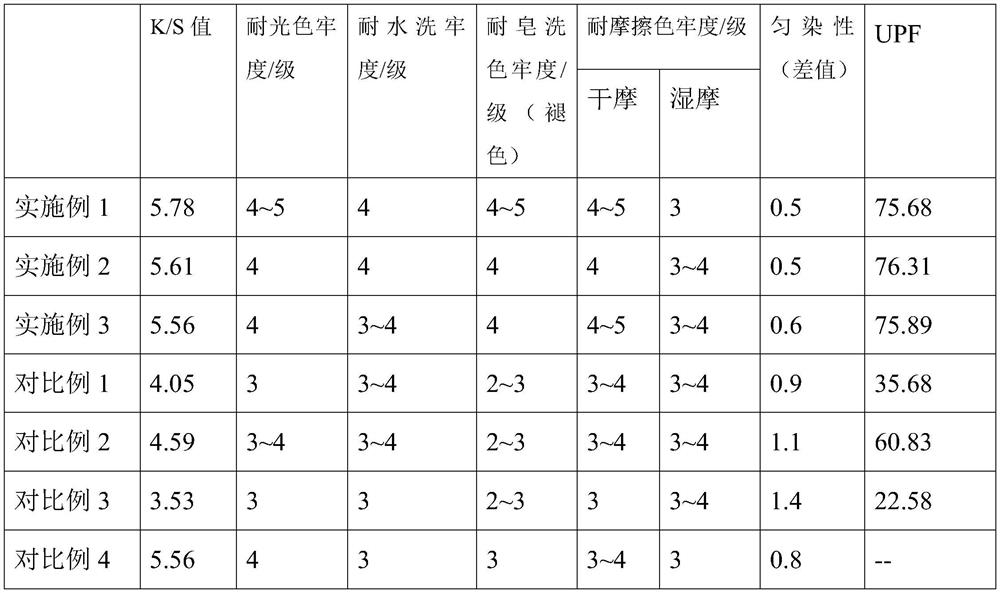

Examples

Embodiment 1

[0031] (1) Extraction of sumac pigment: After washing and drying red leaf sumac (leaves that turn red in autumn, from late October to early November), add water to soak for 2 hours at a mass ratio of 1:10, decoct for 90 minutes, filter, and collect The filtrate, adding the filter residue into water and decocting twice, combined the filtrate, concentrated it to 35% of the original volume by rotary evaporation, dried it in a vacuum oven to obtain the sumac pigment, and ground it into a 70-mesh powder.

[0032] (2) In parts by weight, take by weighing 55 parts of sumac pigments, 4 parts of nano titanium dioxide sol (mass concentration 20%), 3 parts of dopamine hydrochloride, 180 parts of water; add nano titanium dioxide sol successively under the dark environment And dopamine hydrochloride, sumac pigment, after stirring and mixing, adjust pH 6.5 with Tris-HCl buffer solution (0.05mol / L, pH 6.5), obtain sumac pigment dye mixture, keep away from light for subsequent use;

[0033] (...

Embodiment 2

[0038] (1) Extraction of sumac pigment: After washing and drying the red leaf sumac, put it in water at a mass ratio of 1:13, soak for 1 hour, decoct for 60 minutes, filter, collect the filtrate, add the filter residue into water and repeat decocting for 3 times, combine the filtrate, and rotate Concentrate by evaporation to 30% of the original volume, dry in a vacuum oven to obtain the sumac pigment, and grind it into a 60-mesh powder.

[0039] (2) In parts by weight, take by weighing 60 parts of sumac pigment, 3 parts of nano titanium dioxide sol (mass concentration 20%), 5 parts of dopamine hydrochloride, 200 parts of water; add nano titanium dioxide sol successively under the dark environment And dopamine hydrochloride, sumac pigment, after stirring and mixing, adjust pH 6.5 with Tris-HCl buffer solution (0.05mol / L, pH 6.5), obtain sumac pigment dye mixture, keep away from light for subsequent use;

[0040] (3) In parts by mass: 20 parts of bentonite, 7 parts of guar gum, ...

Embodiment 3

[0045] (1) Extraction of sumac pigment: After washing and drying the red leaf sumac, put it in water at a mass ratio of 1:15, soak it for 2 hours, decoct it for 90 minutes, filter it, collect the filtrate, add the filter residue into water and repeat decocting for 3 times, then combine the filtrate, rotate Concentrate by evaporation to 40% of the original volume, dry in a vacuum oven to obtain the sumac pigment, and grind it into an 80-mesh powder.

[0046] (2) In parts by weight, take by weighing 60 parts of sumac pigments, 5 parts of nano titanium dioxide sol (mass concentration 20%), 5 parts of dopamine hydrochloride, 200 parts of water; (mass concentration 20%), dopamine hydrochloride, and sumac pigment are added sequentially, after stirring and mixing, adjust pH 6.5 with Tris-HCl buffer solution (0.05mol / L, pH 6.5) to obtain the sumac pigment dye mixture, and keep away from light for subsequent use ;

[0047] (3) In parts by mass: 20 parts of bentonite, 20 parts of guar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com