Perovskite thin film and preparation method and application thereof

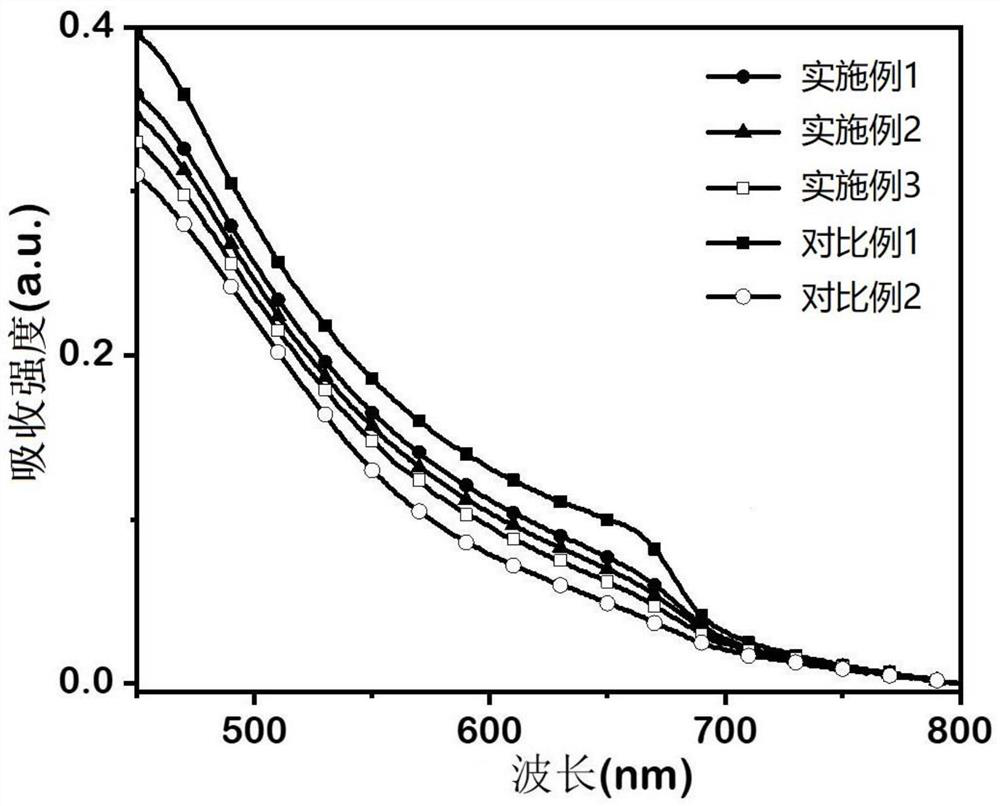

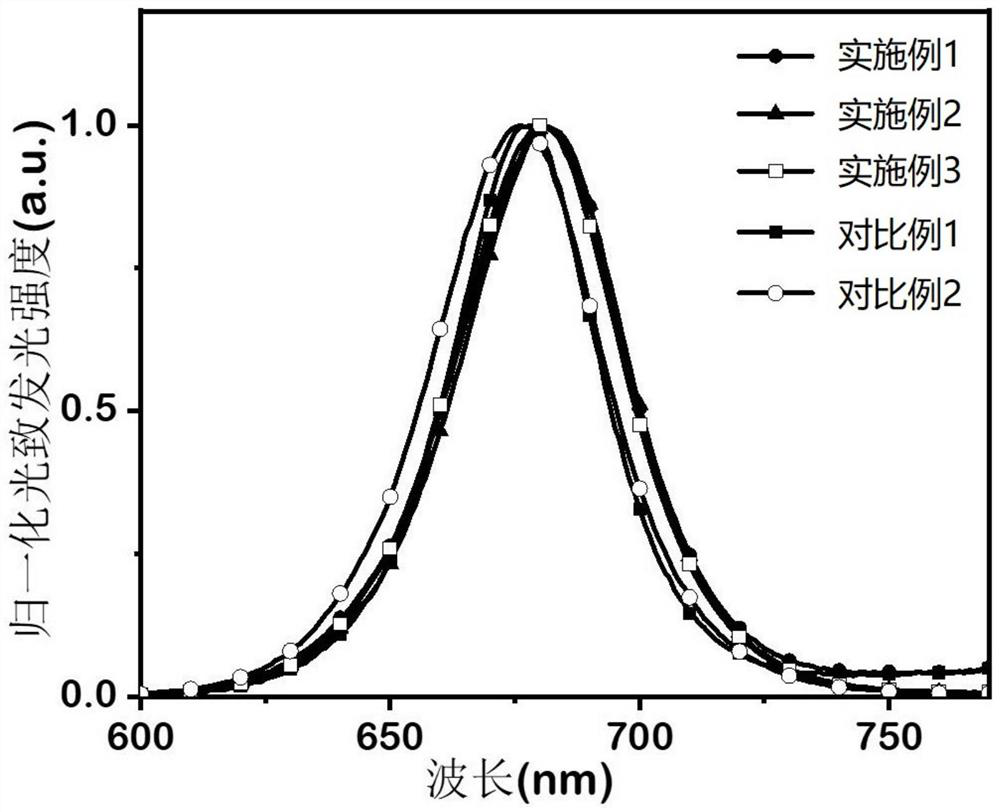

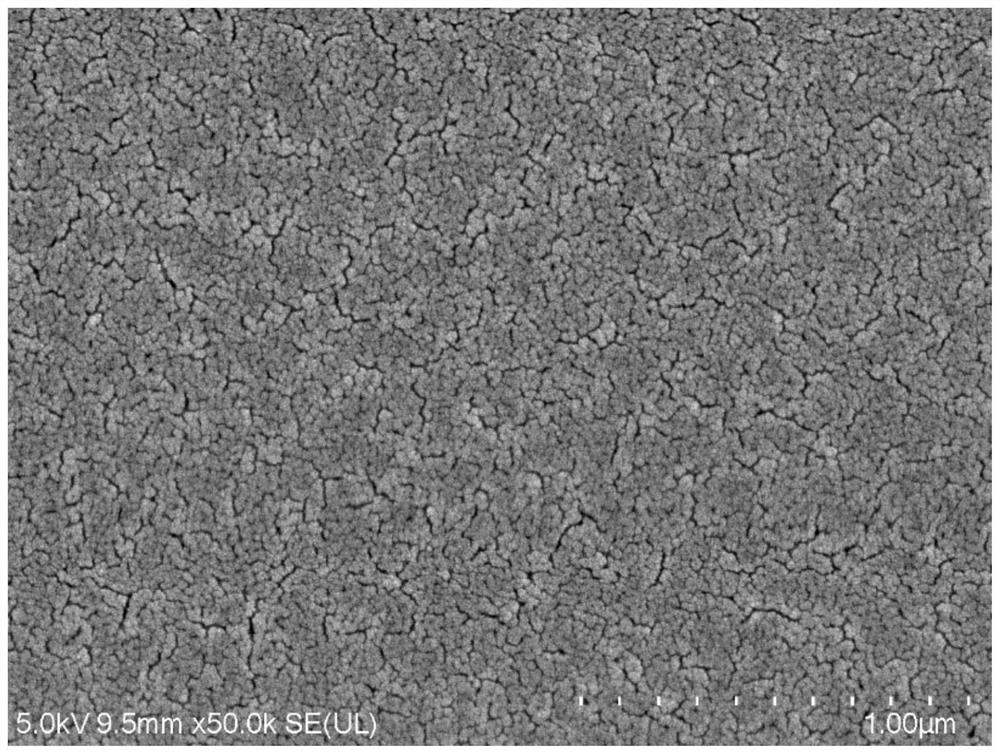

A technology of perovskite and perovskite precursors, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problem of low exciton binding energy, low film quality, excessive grain growth, etc. problem, to achieve the effect of high exciton binding energy, low defect state density, and large exciton binding energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A kind of perovskite film, its preparation method comprises the following steps:

[0060] 1) Add 0.1mmol (25.98mg) of CsI, 0.1mmol (21.28mg) of CsBr and 0.2mmol (92.2mg) of PbI 2 Add 1mL of dimethylformamide (DMF), heat to 60°C under nitrogen atmosphere, stir for 8h to obtain CsPbBr 0.5 I 2.5 Perovskite precursor solution;

[0061] 2) Add 0.16 mmol (27.664 mg) of ethyl ammonium iodide into 1 mL of dimethylformamide (DMF), heat to 60° C. under a nitrogen atmosphere, and stir for 4 hours to obtain ethyl ammonium iodide solution;

[0062] 3) Add 200 μL of CsPbBr 0.5 I 2.5 The perovskite precursor solution was mixed with 100 μL of ethyl ammonium iodide solution, heated to 50°C in a nitrogen atmosphere, kept for 12 hours, and then the obtained mixed solution was spin-coated. The spin-coating machine speed was 6000rmp, and the spin-coating time was 40s, and then put the obtained film on a heating platform for annealing, the annealing temperature is 85°C, and the annealin...

Embodiment 2

[0068] A kind of perovskite film, its preparation method comprises the following steps:

[0069] 1) Add 0.1mmol (25.98mg) of CsI, 0.1mmol (21.28mg) of CsBr and 0.2mmol (92.2mg) of PbI 2 Add 1mL of dimethylformamide (DMF), heat to 60°C under nitrogen atmosphere, stir for 8h to obtain CsPbBr 0.5 I 2.5 Perovskite precursor solution;

[0070] 2) Add 0.2 mmol (34.58 mg) of ethyl ammonium iodide into 1 mL of dimethylformamide (DMF), heat to 60° C. under a nitrogen atmosphere, and stir for 4 hours to obtain ethyl ammonium iodide solution;

[0071] 3) Add 200 μL of CsPbBr 0.5 I 2.5 The perovskite precursor solution was mixed with 100 μL of ethyl ammonium iodide solution, heated to 50°C in a nitrogen atmosphere, kept for 12 hours, and then the obtained mixed solution was spin-coated. The spin-coating machine speed was 6000rmp, and the spin-coating time was 40s, and then put the obtained film on a heating platform for annealing, the annealing temperature is 85°C, and the annealing ...

Embodiment 3

[0078] A kind of perovskite film, its preparation method comprises the following steps:

[0079] 1) Add 0.1mmol (25.98mg) of CsI, 0.1mmol (21.28mg) of CsBr and 0.2mmol (92.2mg) of PbI 2 Add 1mL of dimethylformamide (DMF), heat to 60°C under nitrogen atmosphere, stir for 8h to obtain CsPbBr 0.5 I 2.5 Perovskite precursor solution;

[0080] 2) Add 0.24 mmol (41.496 mg) of ethyl ammonium iodide into 1 mL of dimethylformamide (DMF), heat to 60° C. under a nitrogen atmosphere, and stir for 4 hours to obtain ethyl ammonium iodide solution;

[0081] 3) Add 200 μL of CsPbBr 0.5 I 2.5 The perovskite precursor solution was mixed with 100 μL of ethyl ammonium iodide solution, heated to 50°C in a nitrogen atmosphere, kept for 12 hours, and then the obtained mixed solution was spin-coated. The spin-coating machine speed was 6000rmp, and the spin-coating time was 40s, and then put the obtained film on a heating platform for annealing, the annealing temperature is 85°C, and the annealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com