Anti-cracking polyethylene photovoltaic cable material and preparation method thereof

A photovoltaic cable, polyethylene technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as limited effect, achieve the effect of inhibiting hydrolysis, ensuring structural stability, and increasing surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

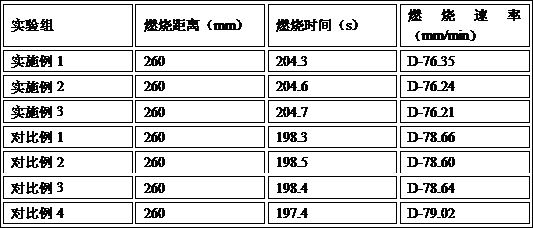

Examples

Embodiment 1

[0029] A kind of anti-cracking polyethylene photovoltaic cable material, the raw materials of each component are as follows, in parts by weight, including 10 parts of cross-linked polyethylene, 5 parts of polyvinyl chloride, 5 parts of heat stabilizer, 2 parts of plasticizer, hardener 2 parts, 2 parts of colorant, 2 parts of lubricant, 2 parts of flame retardant, 2 parts of zirconium dioxide.

[0030] The raw materials of each component of the heat stabilizer are as follows, in parts by weight, 4 parts of phenol, 10 parts of methyl tin heat stabilizer, and 5 parts of barium zinc stabilizer.

[0031] The raw materials of each component of the lubricant are as follows, in parts by weight, 1 part of sodium stearate and 1 part of magnesium stearate.

[0032] The raw materials of each component of the hardening agent are as follows, in parts by weight, including 2 parts of cellulose and 2 parts of glass fiber.

[0033] The raw materials of each component of the plasticizer are as ...

Embodiment 2

[0044] A kind of anti-cracking polyethylene photovoltaic cable material, the raw materials of each component are as follows, in parts by weight, including 13 parts of cross-linked polyethylene, 6 parts of polyvinyl chloride, 6 parts of heat stabilizer, 3 parts of plasticizer, hardener 3 parts, 2 parts of colorant, 3 parts of lubricant, 3 parts of flame retardant, 3 parts of zirconium dioxide.

[0045] The raw materials of each component of the heat stabilizer are as follows, in parts by weight, 5 parts of phenol, 13 parts of methyl tin heat stabilizer, and 6 parts of barium zinc stabilizer.

[0046] The raw materials of each component of the lubricant are as follows, in parts by weight, 2 parts of sodium stearate and 2 parts of magnesium stearate.

[0047]The raw materials of each component of the hardening agent are as follows, in parts by weight, including 3 parts of cellulose and 3 parts of glass fiber.

[0048] The raw materials of each component of the plasticizer are as...

Embodiment 3

[0059] A kind of anti-cracking polyethylene photovoltaic cable material, the raw materials of each component are as follows, in parts by weight, including 15 parts of cross-linked polyethylene, 7 parts of polyvinyl chloride, 7 parts of heat stabilizer, 4 parts of plasticizer, hardener 4 parts, 3 parts of colorant, 4 parts of lubricant, 4 parts of flame retardant, 4 parts of zirconium dioxide.

[0060] The raw materials of each component of the heat stabilizer are as follows, in parts by weight, 6 parts of phenol, 15 parts of methyl tin heat stabilizer, and 8 parts of barium zinc stabilizer.

[0061] The raw materials of each component of the lubricant are as follows, in parts by weight, 2 parts of sodium stearate and 2 parts of magnesium stearate.

[0062] The raw materials of each component of the hardener are as follows, in parts by weight, including 4 parts of cellulose and 4 parts of glass fiber.

[0063] The raw materials of each component of the plasticizer are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com