Codonopsis pilosula alkyne glycoside sustained-release micro-capsule preparation and preparation method thereof

A technology of Codonopside and sustained-release, which is applied in the field of Codonopside sustained-release microcapsule preparation and its preparation, can solve the problem of not finding a patent for sustained-release preparation, and achieve the advantages of adaptability, reduce the number of doses, and shorten the half-life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The embodiment of the present invention relates to a slow-release microcapsule preparation and a preparation method of a tangshenoside compound, in terms of weight percentage, comprising:

[0053] Codonopsis: 10%-40%;

[0054] Capsule material: 60%-90%;

[0055] The ratio of the capsule material to the styoside is 4:1-6:1;

[0056] The capsule material is a positively and / or negatively charged carrier material;

[0057] The capsule material also includes curing cross-linking agent, wetting agent, pH regulator and deionized water.

[0058] The capsule material is gelatin or one or more combinations of gum arabic, peach gum, psyllium seed gum, cellulose acetate phthalate, sodium carboxymethyl cellulose and alginate.

[0059] Among them, gelatin is a positively charged capsule material.

[0060] Among them, gum arabic, peach gum, psyllium seed gum, cellulose acetate phthalate, sodium carboxymethyl cellulose, and alginate are negatively charged capsule materials.

[00...

Embodiment 1

[0078]

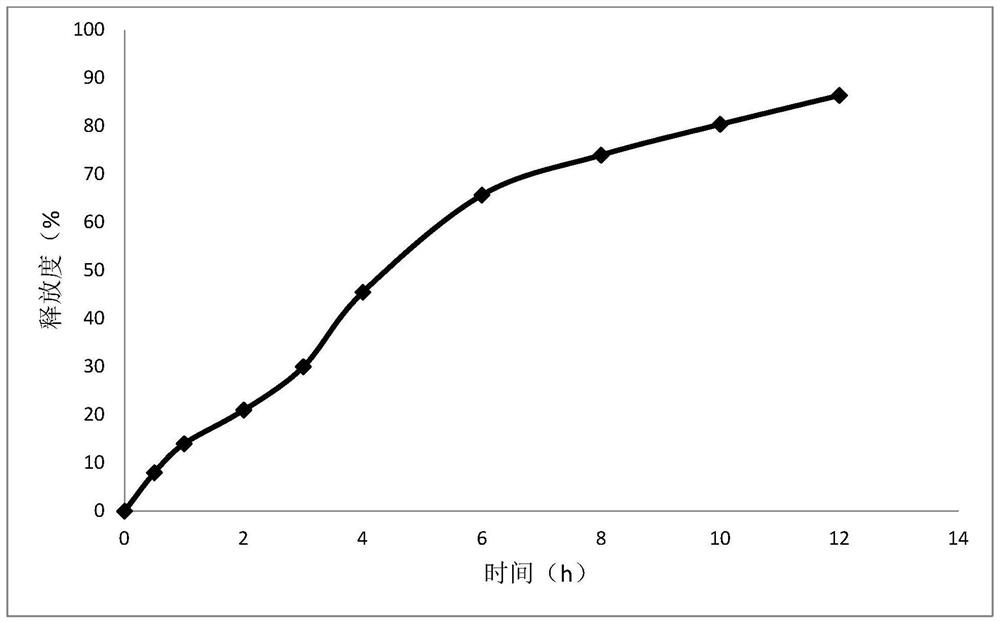

[0079] Add gelatin to 1% calcium chloride solution, add hydrochloric acid solution dropwise to adjust the pH value to 6.1, and obtain the first capsule material solution; prepare sodium alginate into a 3 mg / ml solution, add tangshenoside, stir and mix, And keep the solution temperature at 50° C. to obtain the second capsule material solution. Place the first capsule material solution on a magnetic stirrer, set the stirring speed at 300rpm under the condition of 50°C, slowly add the above-mentioned second capsule material solution into capsule material solution 1, stir for 30 minutes, cool down, and let it stand After settling, the supernatant was decanted, washed with water, filtered, and the obtained microcapsules were vacuum-dried at 50°C. bottling. The yield of tangshenoside sustained-release microcapsules was 90.8%, the encapsulation rate was 74.3%, the drug loading was 21.7%, the cumulative release rate in 4 hours was 45.5%, and the cumulative release rate in...

Embodiment 2

[0081]

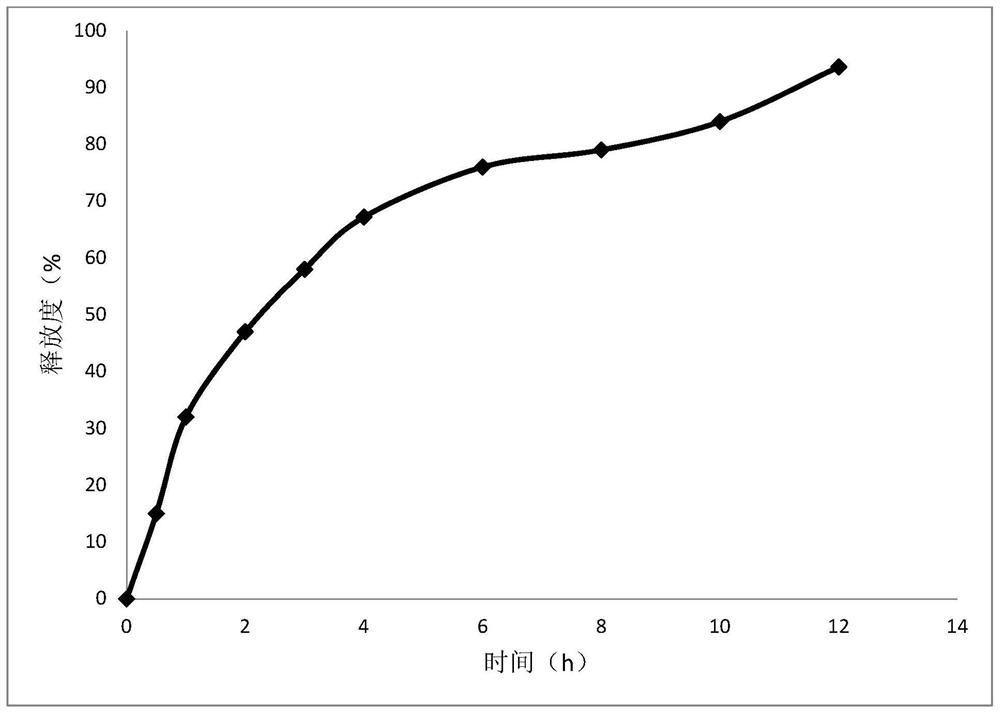

[0082] Dissolve gelatin in a water bath at 50°C to prepare a 30 mg / ml solution to obtain capsule material solution 1; weigh tangshenoside and gum arabic, slowly add a small amount of water at 50°C, grind evenly, transfer to a beaker, add water To a sufficient amount of 835ml, put it on a magnetic stirrer, set the stirring speed to 500rpm, and the temperature to 50°C; slowly add the gelatin solution, and stir for 30 minutes. Acetic acid solution was added dropwise to adjust the pH value to 3.8, and stirring was continued for 20 minutes. After forming capsules, add water to dilute 2 times, and then rapidly cool down to below 10°C in an ice bath. Add formaldehyde solution, adjust the pH value to 8.6 with 20% sodium carbonate solution, stir for 10 minutes, let it settle, pour off the supernatant, filter, wash with water, and the obtained microcapsules are vacuum-dried at 50°C. bottling. The yield of tangshenoside sustained-release microcapsules was 89.4%, the encapsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com