Production technology of fingolimod microcapsules

A production process and microcapsule technology, applied in the direction of organic active ingredients, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of large dosage and frequency, heavy burden on the kidneys, and difficult patient acceptance, etc. problem, to achieve the effect of small dosage, less adverse reactions and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

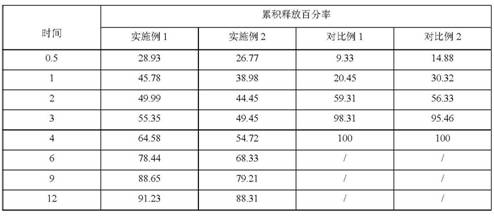

Examples

Embodiment 1

[0032] A production process of fingolimod microcapsules, the following components in the weight-number ratio of each raw material of fingolimod microcapsule preparations: 10 parts of fingolimod bulk drug, 2 parts of surfactant, 1 part of solubilizer 1 part, 1 part of ethyl cellulose, 1 part of methyl cellulose, 5 parts of microcrystalline cellulose, 1 part of gum arabic, 1 part of gelatin, 1 part of fructooligosaccharide, 1 part of isomaltooligosaccharide;

[0033] The preparation method of fingolimod microcapsule preparation is as follows:

[0034] (1) Preparation of capsule material solution

[0035] Add 45-50% ethanol aqueous solution into the mixer, add ethyl cellulose, methyl cellulose, microcrystalline cellulose, gum arabic, gelatin, fructo-oligosaccharide and isomalto-oligosaccharide in turn while stirring, and stir to make capsules material solution a;

[0036] (2) Preparation of suspension

[0037] Adding the fingolimod raw material drug to peanut oil to obtain a f...

Embodiment 2

[0045] A production process of fingolimod microcapsules, the difference from Example 1 is: the following components of the ratio of the weight and number of each raw material of fingolimod microcapsule preparation: 20 parts of fingolimod bulk drug , 6 parts of surfactant, 2 parts of solubilizer, 5 parts of ethyl cellulose, 10 parts of methyl cellulose, 20 parts of microcrystalline cellulose, 5 parts of gum arabic, 10 parts of gelatin, 5 parts of fructooligosaccharide, oligosaccharide 5 parts of isomaltose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com