Mineral admixture and preparation method thereof

A technology of mineral admixtures and raw materials, applied in the field of building materials, can solve the problems of polluting the atmosphere, soil and water resources in surrounding areas, engineering quality problems, and volume stability deterioration, etc., to achieve large-scale and high added value. Effectiveness of utilization, reduction of energy consumption and carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

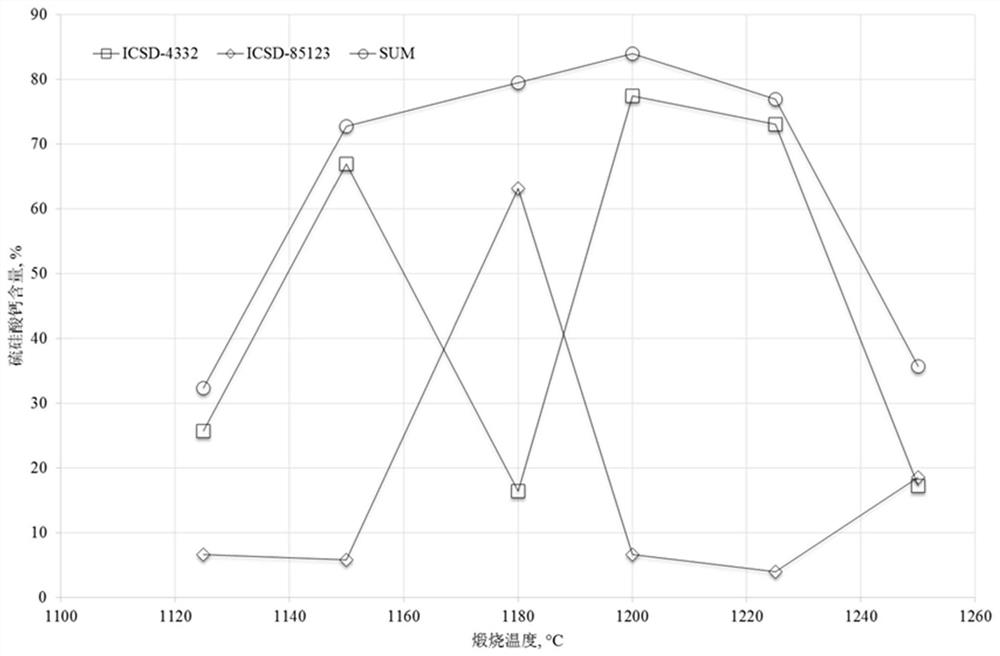

[0055] Use low-grade limestone, desulfurization gypsum, molybdenum tailings and chemical solid waste mineralizer containing calcium fluoride to mix according to the ratio of 58%: 19.0%: 22.0%: 1.0%, and use a ball mill to grind until the mixture is larger than 90 microns The particles are less than 1%; then, add a small amount of water to the mixture, stir it evenly, and press it into a test cake with a thickness of about 2cm and a diameter of 5cm; then, put the test cake into a high-temperature electric furnace for calcination, and the heating rate of the electric furnace is 15 °C / min, calcined at 1180 °C for 30 min, and then rapidly cooled to room temperature to obtain the product. Wherein, SiO in the molybdenum tailings 2 、Al 2 o 3 、Na 2 O, K 2 O and Fe 2 o 3 The contents of calcium oxide in the low-grade limestone are 65.93%, 13.31%, 2.51%, 2.47%, and 3.58%, respectively; the content of calcium oxide in the low-grade limestone is 46.3%; 2 The content is 17.2%.

[0...

Embodiment 2

[0060] Use papermaking white mud, desulfurization gypsum, gold tailings and manganese oxide-containing manganese slag industrial solid waste mineralizer to mix according to the ratio of 65%: 15.0%: 18.0%: 2.0%, and use a ball mill to grind until the mixture is greater than 90% The micron particles are less than 1%; then, add a small amount of water to the mixture, stir evenly, and use a press to press into a test cake with a thickness of about 2cm and a diameter of 5cm; then, put the test cake into a high-temperature electric furnace for calcination, and the heating rate of the electric furnace is 15°C / min, calcined at 1230°C for 20min, and then rapidly cooled to room temperature to obtain the product. Wherein, the SiO in the gold tailings 2 、Al 2 o 3 、Na 2 O, K 2 O and Fe 2 o 3 The content of calcium oxide in the paper-making lime mud is 64.6%, 10.8%, 1.98%, 3.01%, and 7.6%, respectively; the content of calcium oxide in the white mud for papermaking is 51.0%; The manga...

Embodiment 3

[0064] Use calcium carbide slag, phosphogypsum, coal gangue and copper oxidized copper slag industrial solid waste mineralizer to mix according to the ratio of 48%: 21.0%: 30.0%: 1.0%, and use a ball mill to grind until the mixture is larger than 90 microns The particles are less than 1%; then, add a small amount of water to the mixture, stir it evenly, and press it into a test cake with a thickness of about 2cm and a diameter of 5cm; then, put the test cake into a high-temperature electric furnace for calcination, and the heating rate of the electric furnace is 15 °C / min, calcined at 1150 °C for 30 min, and then rapidly cooled to room temperature to obtain the product. Wherein, SiO in the gangue 2 、Al 2 o 3 、Na 2 O, K 2 O and Fe 2 o 3 The content of calcium oxide in the calcium carbide slag is 58.97%, 23.55%, 0.48%, 1.32%, 2.71% respectively; the calcium oxide content in the calcium carbide slag is 68.1%; the copper slag industrial solid waste mineralizer containing cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com