A kind of method utilizing phosphogypsum to produce α-hemihydrate gypsum

A technology of hemihydrate gypsum and phosphogypsum, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium sulfate, etc., can solve the problems of no industrial value and high processing cost, shorten the conversion time and increase the ionic strength , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

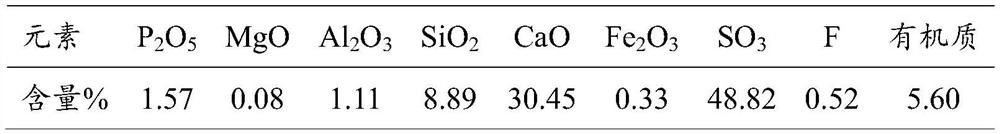

[0027] Weigh 1kg of phosphorus gypsum, add 1kg of tap water, and mix into a homogeneous slurry. Transferred into the rod mill, the grinding is 5min, and the grinding fineness is determined to be -200 mesh 90%. Thick to 50% phosphogypsum concentration, transferred to the cyclone, adjust the stirring speed of 60r / min, inlet water velocity of 10mL / min to separate the upper foam slurry overflow. After the foam overflow is completed, adjust the stirring speed to 300r / min, the inlet water speed is 50mL / min, open the middle valve of the cyclone to flow out of the phosphogypsum solution until the outflow liquid has a solid content of 10%. The foam liquid was filtered to obtain organic matter and dried to 60.4g; the phosphogypsum solution was filtered to obtain pretreated phosphogypsum, which was naturally dried to obtain 840g pretreated phosphogypsum; the solids at the bottom of the cyclone filtered to obtain silica slag, which was dried to 90.3g. Washing water is recycled, but its P 2 O ...

Embodiment 2

[0032] Take 130 of Example 1 after drying phosphogypsum naturally transferred into the crucible, placed in a muffle furnace, heated at a rate of 8 ° C / min to 500 ° C calcination for 2 hours, natural cooling cooling to room temperature to obtain calcined phosphogypsum 115g.

[0033] Calcined phosphorus gypsum with 100mL acidity of 1nol / dm 3 ,Ca 2+ / Mg 2+ / PO 4 3- / H + The ratio of 2.34:1.48:0.118:1 solution was mixed, transferred to the transcrystalline kettle, heated to 90 °C, the reaction was 90min, filtered while hot, washed once with hot water, to give α - hemihydrous gypsum 46.2g. Filtered to obtain an aqueous solution added ammonium sulfate to remove calcium ions, and then with ammonia water and to pH of 7, precipitated ammonium magnesium phosphate, used for mineral processing grinding water.

[0034] 46.2g α- hemihydrous gypsum was added to the α-sulfonyl fatty acid soap solution at 90 ~ 105 ° C, the reaction continued for 30min at this temperature, and then into the air,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com