Composite phosphorus-free corrosion and scale inhibitor applied to dry quenching waste heat boiler and preparation method

A waste heat boiler, phosphorus-free corrosion inhibition technology, applied in chemical instruments and methods, descaling and water softening, natural water treatment, etc. problems such as scale, achieve good synergy and compatibility, reduce the number of chemical cleaning, and reduce the increase in salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

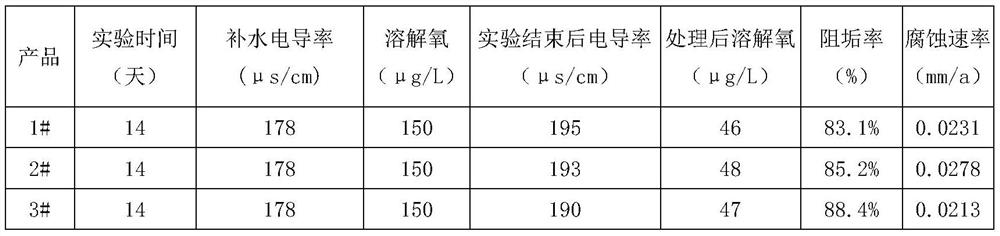

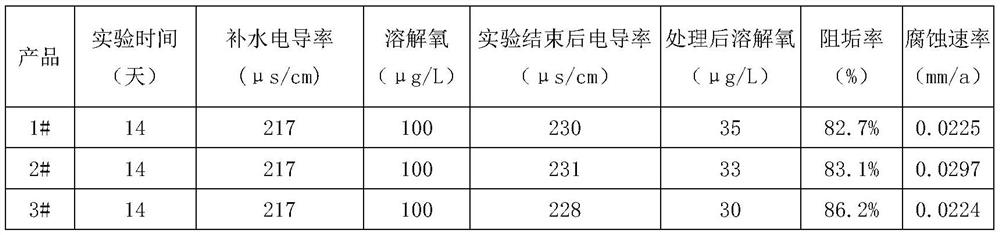

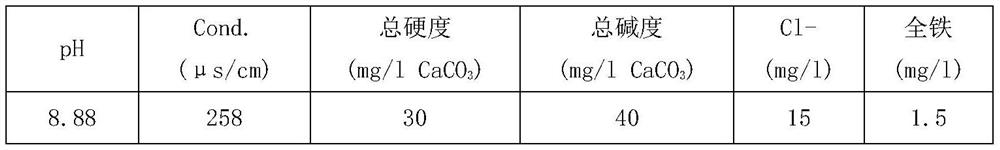

Embodiment 1

[0027] A composite non-phosphorus corrosion and scale inhibitor applied to coke dry quenching waste heat boilers. The proportion of components is hydroxypropyltrimethylammonium chloride chitosan: 26 parts, sodium gluconate: 34 parts, N-isopropyl Hydroxylamine: 18 parts, polyaspartic acid: 18 parts, glucoside: 12 parts, sodium hydroxide: 8 parts, ultrapure water: 30 parts.

[0028] The preparation method of the compound scale and corrosion inhibitor in this embodiment is as follows:

[0029] At room temperature, inject ultrapure water into a pressure-bearing reactor, heat it to 45°C, and then perform vacuum treatment, and use a direct-connected liquid ring vacuum pump to exhaust the air. The ultimate vacuum pressure reaches 0.095MPa, and then pass through the reserved Add hydroxypropyltrimethylammonium chloride chitosan, sodium gluconate and N-isopropylhydroxylamine to the airtight dosing port device (has been vacuumized), mix and stir for 30min, after all dissolve, add polyasp...

Embodiment 2

[0031] A composite non-phosphorus corrosion and scale inhibitor applied to CDQ waste heat boilers. Component ratio: hydroxypropyltrimethylammonium chloride chitosan: 22 parts, sodium gluconate: 38 parts, N-isopropyl Hydroxylamine: 13 parts, polyaspartic acid: 20 parts, glucoside: 7 parts, sodium hydroxide: 13 parts, ultrapure water: 25 parts.

[0032] The preparation method of the compound scale and corrosion inhibitor in this embodiment is as follows:

[0033] At room temperature, inject ultrapure water into a pressure-bearing reactor, heat it to 60°C, and then perform vacuum treatment, and use a direct-connected liquid ring vacuum pump to exhaust the air. The ultimate vacuum pressure reaches 0.097MPa, and then through the reserved Add hydroxypropyltrimethylammonium chloride chitosan, sodium gluconate and N-isopropylhydroxylamine to the airtight dosing port device (has been vacuumized), mix and stir for 30min, after all dissolve, add polyaspartic acid The amino acid and gluc...

Embodiment 3

[0035] A composite non-phosphorus corrosion and scale inhibitor applied to coke dry quenching waste heat boilers. Component ratio: hydroxypropyltrimethylammonium chloride chitosan: 30 parts, sodium gluconate: 27 parts, N-isopropyl Hydroxylamine: 15 parts, polyaspartic acid: 25 parts, glucoside: 15 parts, sodium hydroxide: 15 parts, ultrapure water: 28 parts.

[0036] The preparation method of the compound scale and corrosion inhibitor in this embodiment is as follows:

[0037]At room temperature, inject ultrapure water into a pressure-bearing reactor, heat it to 55°C, and then perform vacuum treatment, and use a direct-connected liquid ring vacuum pump to exhaust the air. The ultimate vacuum pressure reaches 0.093MPa, and then pass through the reserved Add hydroxypropyltrimethylammonium chloride chitosan, sodium gluconate and N-isopropylhydroxylamine to the airtight dosing port device (has been vacuumized), mix and stir for 30min, after all dissolve, add polyaspartic acid Aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com