Ultrahigh nickel single crystal positive electrode material, preparation method and application

A positive electrode material and single crystal technology, applied in the field of lithium-ion power batteries for new energy vehicles, can solve the problems of low capacity and poor cycle performance of ultra-high nickel single crystal positive electrode materials, and achieve improved battery life and safety performance, layered Stable structure and less agglomeration-like states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

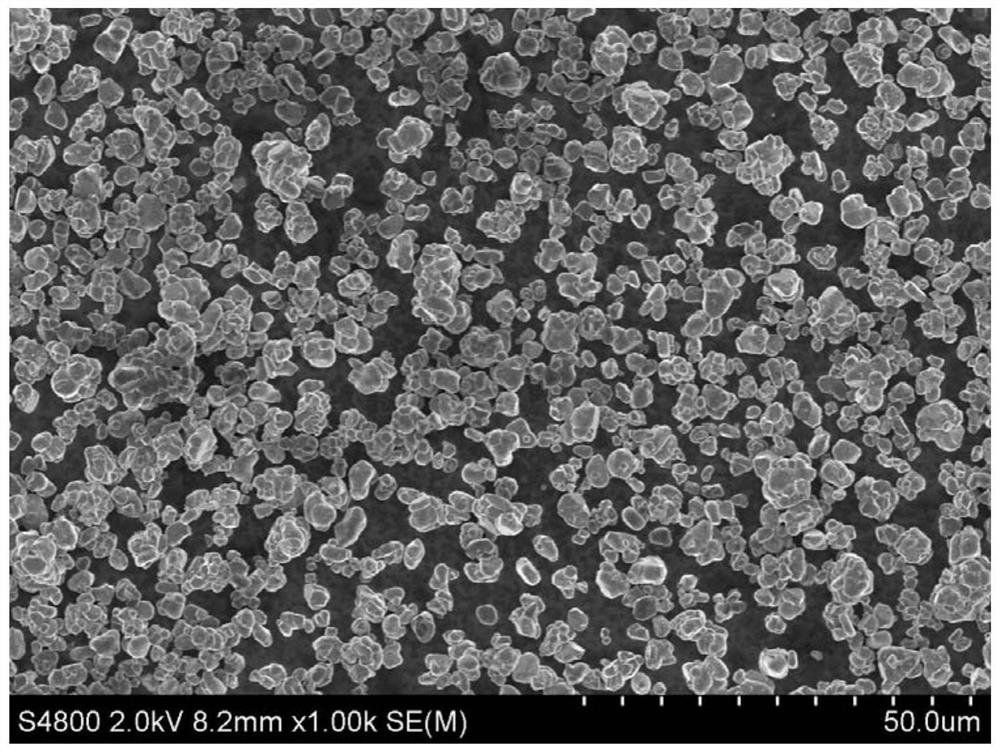

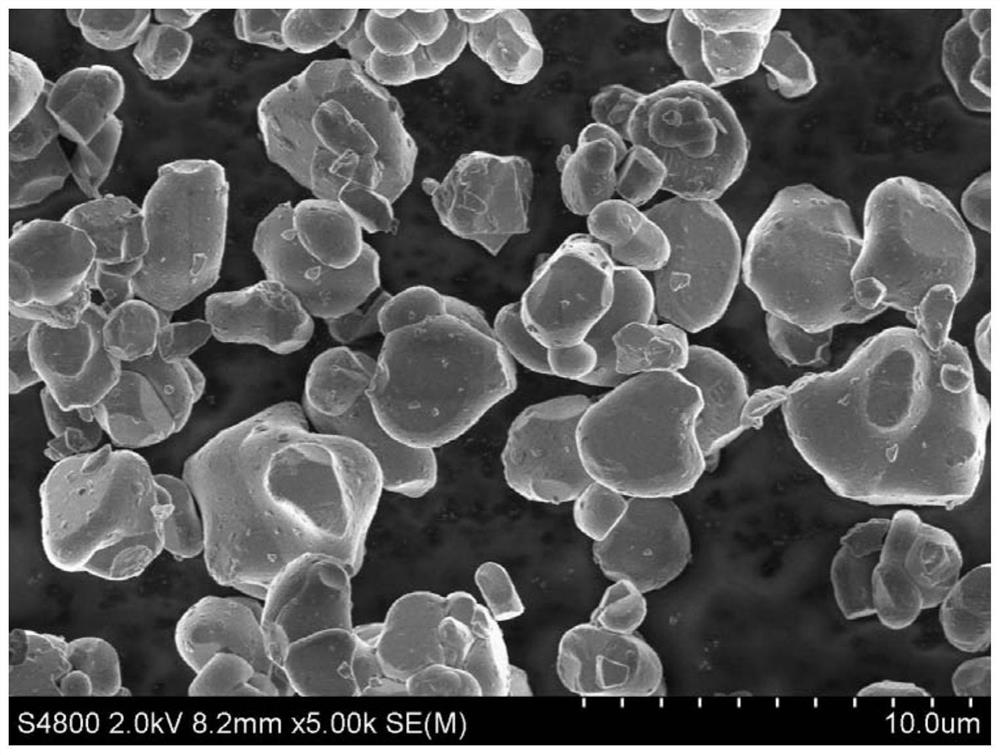

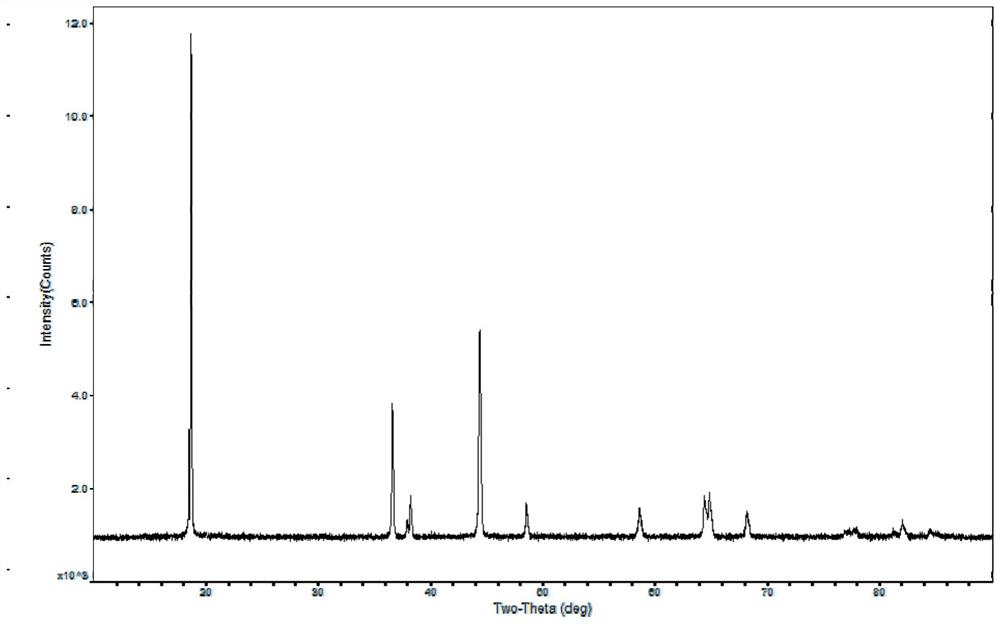

[0042] Preparation of ultra-high nickel single crystal cathode material:

[0043] S1. Put Ni 0.90 co 0.05 mn 0.05 (OH) 2 The ternary precursor is mixed with battery-grade lithium hydroxide monohydrate at a molar ratio of lithium to metal of 1.08:1, and 0.5% Al(OH) containing cobalt-nickel ternary precursor is added 3 and 0.3% ZrO by mass of cobalt-nickel ternary precursor 2 , and then calcined at 790 ° C for 15 hours in an oxygen atmosphere to obtain a primary calcined material; wherein the median particle size D of the ternary precursor 50 3.20μm, the specific surface area is 7.5m 2 / g, bulk density is 1.12g / cm 3 , the tap density is 1.95g / cm 3 ;

[0044] S2. Perform coarse crushing and fine crushing on the primary calcined material, wherein the coarse crushing is crushed by the jaw crusher, and the gap between the rollers is 0.15 mm; the fine crushing parameters are the induced air frequency of 28 Hz, and the classification frequency of 120 Hz;

[0045] S3. The prim...

Embodiment 2

[0048] Preparation of ultra-high nickel single crystal cathode material:

[0049] S1. Put Ni 0.92 co 0.04 mn 0.04 (OH) 2 The ternary precursor is mixed with battery-grade lithium hydroxide monohydrate at a molar ratio of lithium to metal of 1.03:1, and 0.25% Ti(OH) containing cobalt-nickel ternary precursor is added 4 and 0.6% SiO by mass of cobalt-nickel ternary precursor 2 , and then calcined at 770 ° C for 12 hours in an oxygen atmosphere to obtain a primary calcined material; wherein the median particle size D of the ternary precursor contains 50 3.05μm, the specific surface area is 13.5m 2 / g, bulk density is 1.08g / cm 3 , the tap density is 1.87g / cm 3 ;

[0050] S2. The primary calcined material is subjected to coarse crushing and fine crushing, wherein the coarse crushing is crushed by the jaw crusher, and the gap between the rollers is 0.10 mm; the fine crushing parameters are 35 Hz of induced wind frequency and 150 Hz of classification frequency.

[0051] S3. ...

Embodiment 3

[0054] Preparation of ultra-high nickel single crystal cathode material:

[0055] S1. Put Ni 0.88 co 0.09 mn 0.03 (OH) 2 The ternary precursor is mixed with battery-grade lithium hydroxide monohydrate at a molar ratio of lithium to metal of 1.06:1, and 0.07% Sr(OH) containing cobalt-nickel ternary precursor is added 2 and 0.30% Nb by mass of cobalt-nickel ternary precursor 2 o 5 , and then calcined at 810°C for 8 hours in an oxygen atmosphere to obtain a primary calcined material; wherein the median particle size D of the ternary precursor contains 50 3.50μm, the specific surface area is 7.0m 2 / g, bulk density is 1.08g / cm 3 , the tap density is 1.85g / cm 3 ;

[0056] S2. The primary calcined material is subjected to coarse crushing and fine crushing, wherein the coarse crushing is crushed by the jaw crusher, and the gap between the rollers is 0.25 mm; the fine crushing parameters are 5 Hz of induced wind frequency and 100 Hz of classification frequency.

[0057] S3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com