Method for preparing magnetic mesoporous composite adsorbent from natural mixed clay

A composite adsorption and clay technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of activator environmental pollution, complicated purification process, water and energy consumption, etc., to achieve The effect of low cost, simple process and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

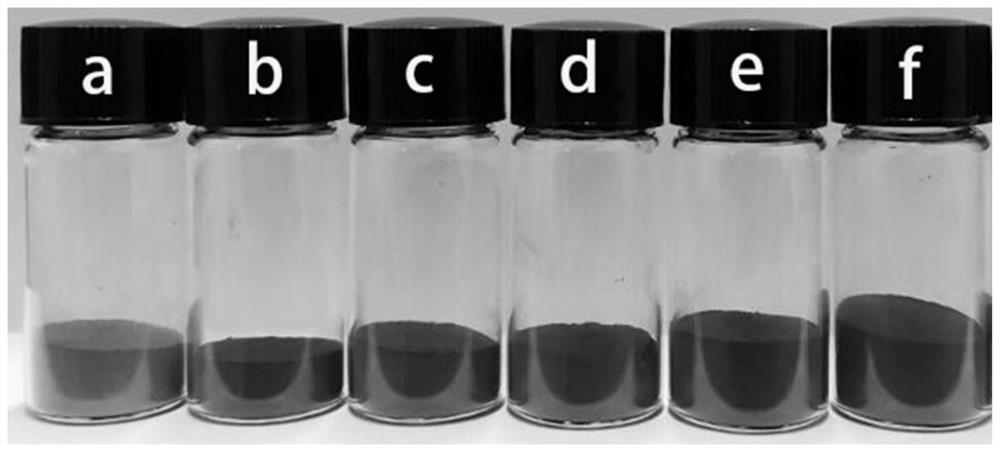

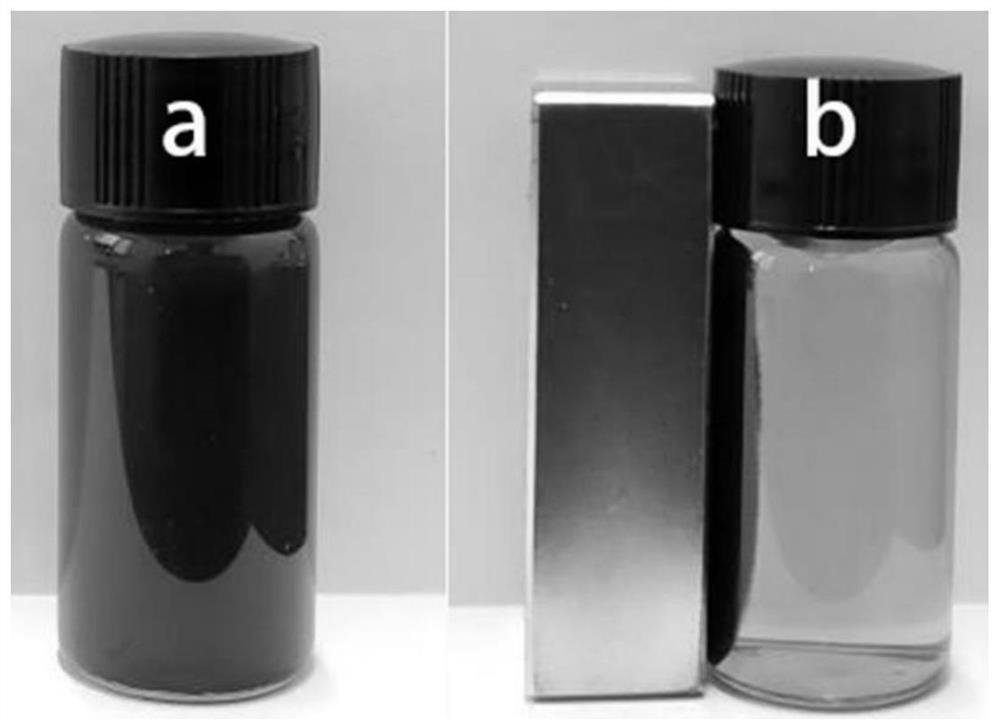

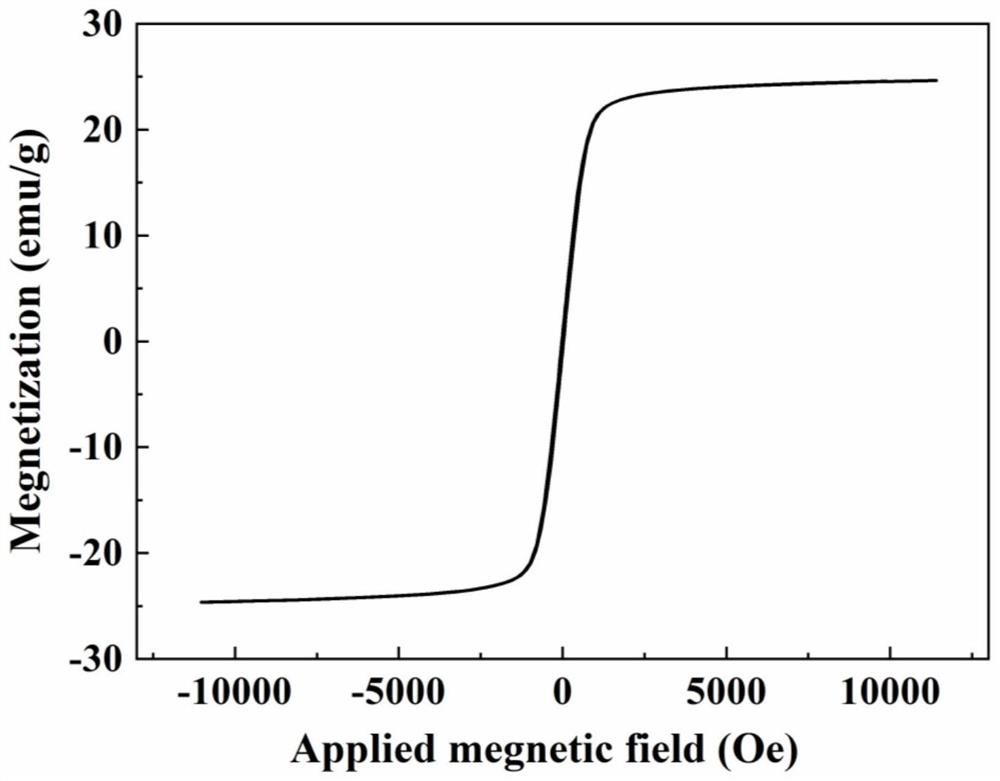

Embodiment 1

[0057] 10kg of natural mixed clay was subjected to air plasma ball milling for 1 hour under the conditions of discharge voltage 8KV, discharge power 1KW and rotation speed 1400rpm to improve the reactivity of clay minerals. Then, the clay mineral treated by plasma ball milling was fully mixed with 5.48 kg of ferrous chloride tetrahydrate and 23.35 kg of solid ferric chloride hexahydrate, and then rolled for 5 times to obtain a thin slice with a thickness of 1 mm. Disperse the flakes in water at a solid-to-liquid ratio of 1:10 under high-speed shearing at 5000rpm to obtain a uniform water suspension, then add 17.71kg of concentrated ammonia (28%) and 9.84kg of triethylamine, and continue heating at 80°C. After aging for 2 hours, a mixture containing magnetic clay minerals and ammonia water was obtained. Add 0.6kg sodium percarbonate, 30kg sodium metasilicate nonahydrate and 0.4kg maleic anhydride to the mixture, then add 0.9234kg magnesium hydroxide and 1.76kg calcium chloride,...

Embodiment 2

[0059] 10kg of natural mixed clay was subjected to air plasma ball milling for 2 hours under the conditions of discharge voltage 12KV, discharge power 2.5KW and rotation speed 950rpm to improve the reactivity of clay minerals. Then, the clay mineral treated by plasma ball milling was fully mixed with 3.60 kg of ferrous sulfate heptahydrate and 10.47 kg of ferric nitrate nonahydrate as solids, and then the rollers were extruded three times to obtain a thin slice with a thickness of 0.25 mm. Disperse the flakes in water at a solid-to-liquid ratio of 1:10 under high-speed shear at 5000rpm to obtain a uniform aqueous suspension, then add 10.62kg of concentrated ammonia water (28%) and 5.90kg of triethylamine, and continue heating at 80°C. After aging for 4 hours, a mixture containing magnetic clay minerals and ammonia water was obtained. Add 0.78kg of sodium percarbonate, 65kg of potassium silicate and 0.65kg of maleic anhydride to the mixture, then add 13.52kg of magnesium oxide ...

Embodiment 3

[0061] 10kg of natural mixed clay was subjected to air plasma ball milling for 2 hours under the conditions of discharge voltage 10KV, discharge power 2.0KW and rotation speed 120rpm to improve the reactivity of clay minerals. Then, the clay mineral treated by plasma ball milling was fully mixed with 2.74 kg of ferrous chloride tetrahydrate and 10.06 kg of ferric acetate solid, and then rolled for 5 times to obtain a thin slice with a thickness of 0.5 mm. Disperse the flakes in water at a solid-to-liquid ratio of 1:10 under high-speed shearing at 5000rpm to obtain a uniform water suspension, then add 14.75kg of concentrated ammonia (28%) and 1.19kg of diethylamine, and continue to heat at 80°C. After aging for 3 hours, a mixture containing magnetic clay minerals and ammonia water was obtained. Add 0.70kg sodium percarbonate, 35kg sodium silicate nonahydrate and 0.5kg maleic anhydride to the mixture, then add 7.59kg magnesium sulfate heptahydrate, 2.53kg calcium nitrate and 2.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com