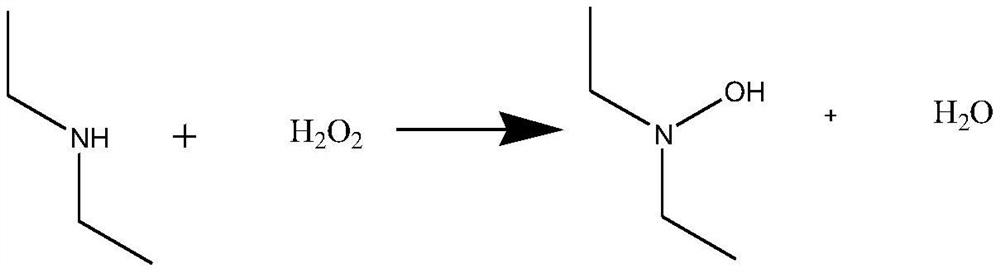

Method for synthesizing diethyl hydroxylamine by using slurry reactor

A technology of diethylhydroxylamine and slurry bed, which is applied in the field of slurry bed synthesis of diethylhydroxylamine, can solve problems such as non-recyclability and post-processing difficulties, and achieve low incidence of side reactions, high effective utilization rate, and high product quality. The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Catalyst pretreatment: Weigh 1.476g of copper nitrate and dissolve it in water, add 50g of TS-1 molecular sieve with a silicon-titanium ratio of 50%; load at 50°C for 2h, dry at 100°C, and bake at 550°C for 6h.

[0026] Weigh 36g of the above-mentioned pretreated catalyst, add it into the slurry bed reactor, mix diethylamine and tetrahydrofuran at a mass ratio of 1:1, and pump them into the slurry tank reactor with 27.5% hydrogen peroxide respectively with a metering pump Carry out the reaction, control the feed rate of hydrogen peroxide to be 36g / h, the mol ratio of diethylamine and hydrogen peroxide to be 2.5:1, control the reaction temperature to be 70°C, the reaction pressure to be 0.1mpa, and the control selectivity in the reaction chromatogram to be 99%, the product and hydrogen peroxide The effective utilization rate is 97.5%, and the reaction yield is 94%.

Embodiment 2

[0028] Catalyst pretreatment: Weigh 1.476g of copper nitrate and dissolve it in water, add 50g of TS-1 molecular sieve with a silicon-titanium ratio of 50%; load at 50°C for 2h, dry at 100°C, and bake at 550°C for 6h.

[0029] Weigh 36g of the above-mentioned pretreated catalyst, add it into the slurry bed reactor, mix diethylamine and tetrahydrofuran at a mass ratio of 1:1, and pump them into the slurry tank reactor with 27.5% hydrogen peroxide respectively with a metering pump Carry out the reaction, control the feed rate of hydrogen peroxide to be 30g / h, the mol ratio of diethylamine and hydrogen peroxide to be 2:1, control the reaction temperature to be 80°C, the reaction pressure to be 0.05mpa, and the control selectivity in the reaction chromatogram to be 99%. The effective utilization rate is 97%, and the reaction yield is 92.5%.

Embodiment 3

[0031] Catalyst pretreatment: Weigh 1.476g of copper nitrate and dissolve it in water, add 50g of TS-1 titanium-silicon molecular sieve with a silicon-to-titanium ratio of 50%; load at 50°C for 2h, dry at 100°C, and bake at 550°C for 6h.

[0032] Weigh 36g of the above-mentioned pretreated catalyst, add it into the slurry bed reactor, mix diethylamine and tetrahydrofuran at a mass ratio of 1:1, and pump them into the slurry tank reactor with 27.5% hydrogen peroxide respectively with a metering pump Carry out the reaction, control the feed rate of hydrogen peroxide to be 18g / h, the mol ratio of diethylamine and hydrogen peroxide to be 2.5:1, control the reaction temperature to be 60°C, the reaction pressure to be 0.05mpa, and the control selectivity in the reaction chromatogram to be 99%, the product and hydrogen peroxide The effective utilization rate is 97.3%, and the reaction yield is 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com