Preparation method of sun-screening agent octyl triazinone

A technology of octyltriazinone and sunscreen agent, applied in the field of preparation of sunscreen agent octyltriazinone, can solve the problems of low preparation yield of intermediate III, difficult to obtain, difficult separation and purification, etc., and achieves simplified reaction composition and The difficulty of solvent separation and recovery, the effect of reducing separation loss and simplifying reaction composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

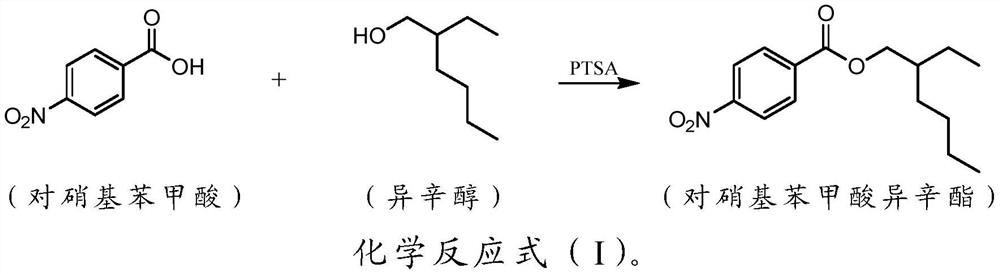

[0037] According to the present invention, a kind of preparation method of sunscreen octyl triazone is provided, the method comprises the following steps:

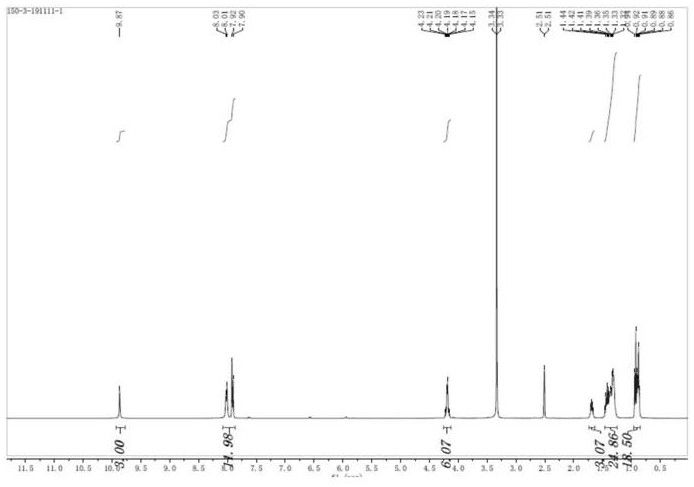

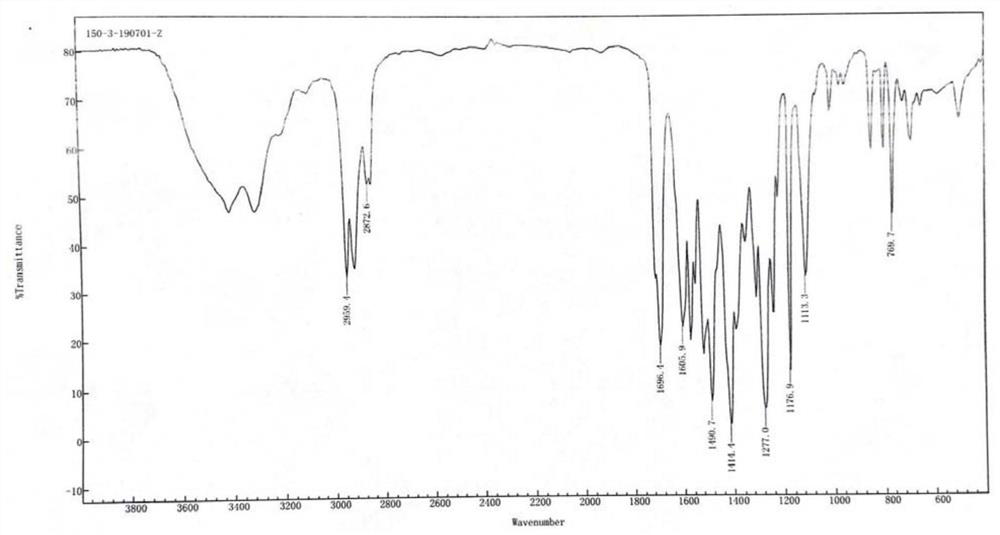

[0038] Step 1, p-nitrobenzoic acid and isooctyl alcohol carry out esterification reaction, obtain product I.

[0039] According to the present invention, in step 1, p-nitrobenzoic acid and iso-octanol are subjected to esterification under reflux in the presence of a catalyst.

[0040] Preferably, the catalyst is one or more of p-toluenesulfonic acid (PTSA) / methanesulfonic acid, methanetrisulfonic acid, perchloric acid, Nafion-H sulfonic acid resin, etc., preferably PTSA.

[0041] According to the present invention, the mol ratio of p-nitrobenzoic acid and isooctyl alcohol is 1: (1.5~3), preferably 1: (2~3), more preferably 1:2; The molar ratio is 1:(0.09-0.2), preferably 1:(0.09-0.1), for example 1:0.093 or 1:0.1.

[0042] According to a preferred embodiment of the present invention, the p-nitrobenzoic acid:isooctanol:ca...

Embodiment 1

[0096] Esterification: Add 250.0g p-nitrobenzoic acid, 390.0g isooctyl alcohol, and 27.0g p-toluenesulfonic acid into a dry and clean four-necked flask, control the vacuum of the water pump at 10-15mmHg, and control the temperature at 89-116°C. After reacting for about 3 hours until p-nitrobenzoic acid remains <0.1%, the reaction is terminated, washed twice with 100 g of tap water, separated to obtain 109.2 g of an aqueous phase containing catalyst p-toluenesulfonic acid, which is used mechanically in the next batch of esterification, and obtained The isooctyl alcohol solution of 619.8g isooctyl p-nitrobenzoate is directly used for hydrogenation reaction;

[0097] Hydrogenation: Put 619.8g isooctyl p-nitrobenzoate in isooctyl alcohol solution, 2.1g Pd / C (~5%, water content~60%), and 223.1g isooctyl into a dry and clean 2L hydrogenation kettle Alcohol; after feeding, close the hydrogenation tank, replace it with nitrogen 3 times, and then replace it with hydrogen 3 times; open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com