Preparation method of intumescent flame-retardant polyurethane

A technology of intumescent flame retardant and polyurethane, which is applied in the field of polymer materials, can solve the problems of polyurethane foam expansion and flame retardant, and achieve the effects of increasing flame retardant efficiency, low cost, and reducing fatality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

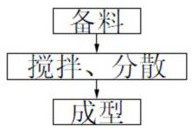

[0019] The invention provides a preparation method of intumescent flame-retardant polyurethane, which solves the problems of dispersion and compatibility of organic flame retardants in polyurethane resins, increases the flame-retardant efficiency of flame retardants, and improves the mechanical properties of polyurethane foams , see figure 1

[0020] The preparation method of this expanded flame-retardant polyurethane comprises the steps:

[0021] S1: Raw materials: polyether trihydric alcohol: 100 parts, polyethylene oxide glycol: 10-40 parts, foaming agent urea: 3-15 parts, foaming agent carbonate organic alcohol amine salt: 2-10 parts, 2- Potassium ethylhexanoate: 0-4 parts, dibutylene dilaurate: 0-4 parts, foam stabilizer: 0-10 parts, copolymerization reaction monomer flame retardant: 15-40 parts, nano aluminum hydroxide : 0-10 parts, ammonium octamolybdate: 0-5 parts, several parts of isocyanate;

[0022] S2: Stirring and dispersing: polyether trihydric alcohol, polyet...

Embodiment 1

[0026] Add 68g (0.5mol) pentaerythritol and 226.7mL (2.5mol) phosphorus oxychloride in four-neck flask, heat up to 80 DEG C of reaction 8 hours, then heat to reflux until no HCl is emitted. Cool to room temperature, filter, wash with chloroform, anhydrous ethanol, and anhydrous ether successively, and vacuum-dry at room temperature for 12 hours to obtain a white solid as bisspirophosphoryl chloride, yield: 84%, melting point: 241-242°C .

[0027] Add 29.7g (0.1mol) double spirophosphoryl chloride and 90mL acetonitrile in a four-neck round bottom flask, add 20mL dropwise at 60°C to dissolve 12.0g (0.2mol) ethylenediamine and 30.3g (0.3mol) triethylene The acetonitrile solution of the amine was reacted for 6 hours, cooled and filtered, and the filter cake was washed with acetonitrile, distilled water and ethanol in sequence, and dried to obtain a solid that was a copolymerized reaction monomer flame retardant, with a yield of 48.2%. Structural characterization of copolymerized ...

Embodiment 2

[0029] The synthetic operation of double spiro phosphorus oxychloride is with embodiment 1, and the synthetic operation of copolymerization reaction monomer flame retardant is with embodiment 1, and in the reaction of compound and ethylenediamine that double spiro phosphorus oxychloride and ethylenediamine reaction make, The amount ratio of the compound prepared by the reaction of double spirophosphoryl chloride and ethylenediamine to ethylenediamine is 1.0:3.2, the solvent is dichloromethane, the acid binding agent is pyridine, the double spirophosphoryl chloride and ethylenediamine The ratio of the compound produced by the reaction to the acid-binding agent was 1.0:2.5, the reaction temperature was 0°C, the reaction time was 10 hours, and the yield was 32.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com