Preparation and application of high-performance Fe, Ce, Mn and Ti four-component catalyst

A catalyst and four-component technology, applied in the direction of catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of poor low-temperature activity and weak poisoning ability, and achieve good mutual contact and low cost The effect of lowering and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

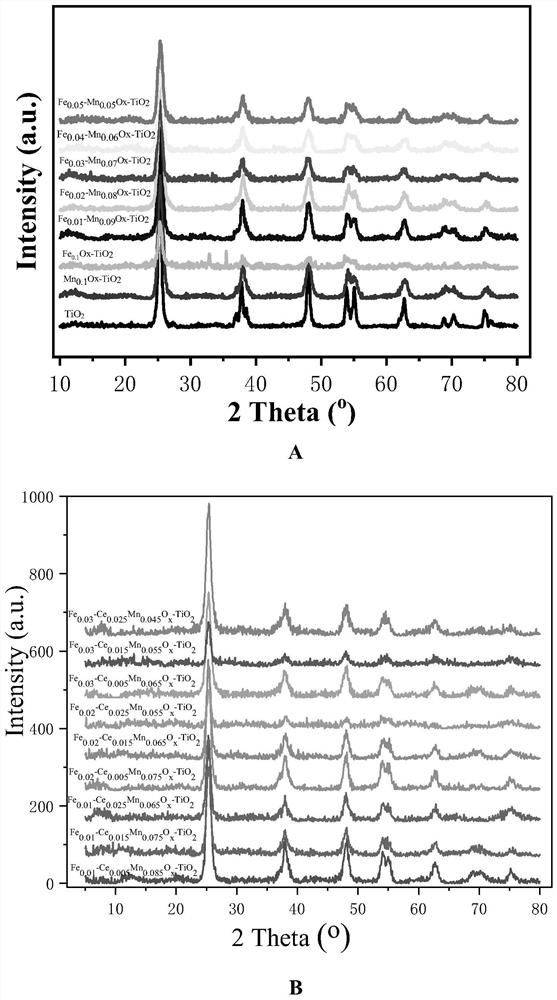

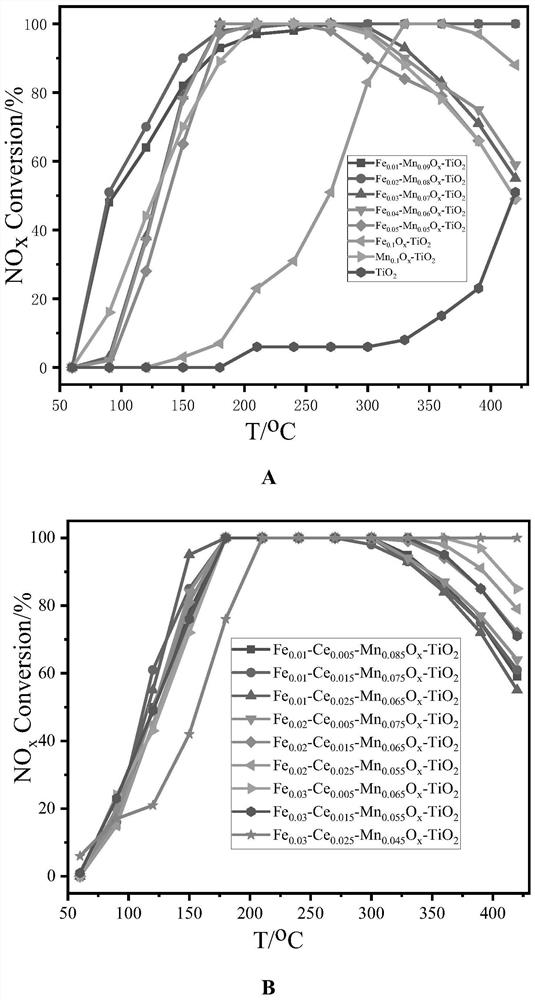

[0036] Substances such as n-butyl titanate, cerium nitrate, iron nitrate and manganese nitrate are all based on the product Fe m -Ce n -Mn 0.1-m-n o x -TiO 2 (0<m≤0.050, 0<n≤0.025) stoichiometric ratio weighing. m=0.01, 0.02, 0.03, 0.04 or 0.05; n=0.005, 0.015 or 0.025.

[0037] S1: Slowly drop n-butyl titanate into the mixture of citric acid, ethanol, glacial acetic acid and deionized water, mix well to form A solution; add cerium nitrate, iron nitrate and manganese nitrate to citric acid, ethanol, ice In the mixture of acetic acid and deionized water, mix evenly to form B solution;

[0038] S2: Mix solution A and solution B, stir at room temperature for 3 hours, take it out and place it in a blast oven at a constant temperature of 30°C to obtain a xerogel;

[0039] S3: drying the xerogel in an oven at 110°C to form a catalyst precursor;

[0040] S4: Grind the catalyst precursor into powder, press into tablets in a muffle furnace, heat up and sinter, cool to room tempe...

Embodiment 2

[0046] TiO 2 , FeO x -TiO 2 (FeO x / TiO 2 =1 / 10), MnO x -TiO 2 (MnO x / TiO 2 = 1 / 10) and Fe 0.01 -MnO x -TiO 2 ((FeO x +MnO x ) / TiO 2 =1 / 10) and other catalysts are similar to the experimental method of Example 1 or adopt existing commercially available materials to carry out tests such as the catalyst activity evaluation of Example 3 as reference substances.

Embodiment 3

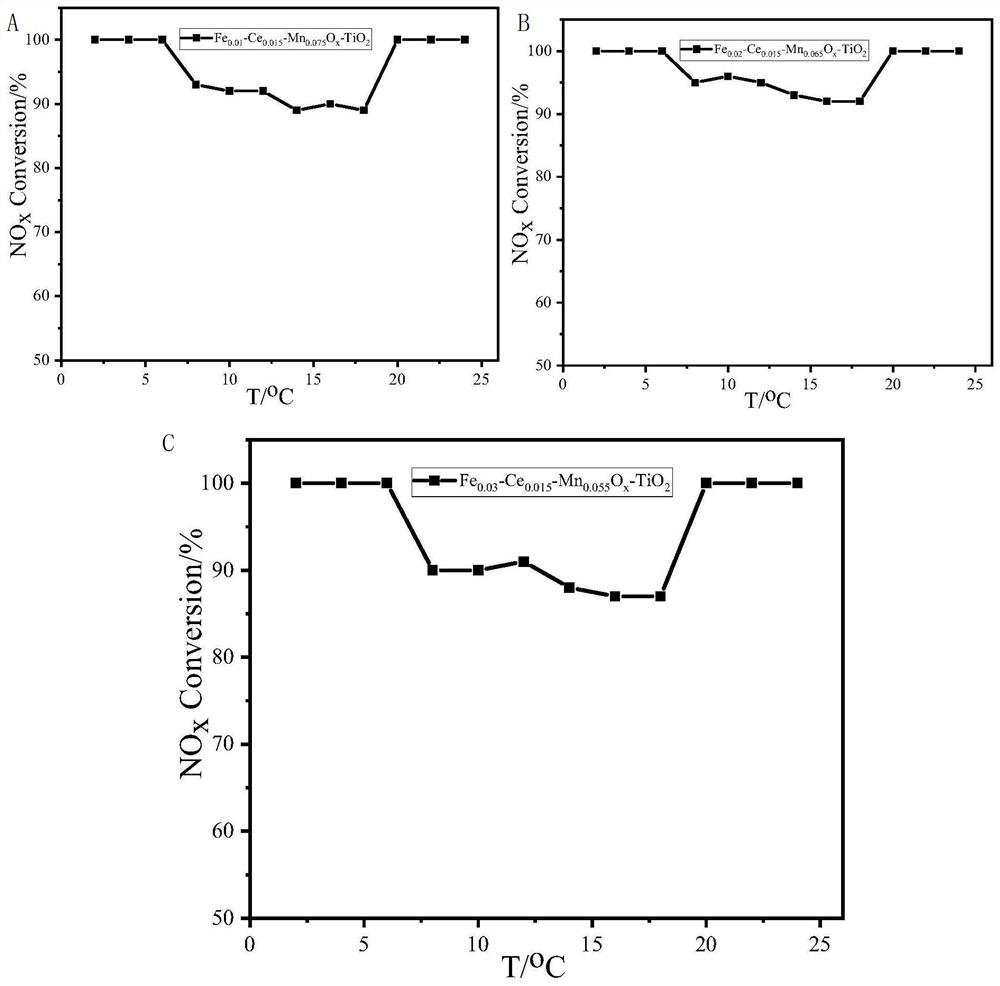

[0048] in H 2 O (gas phase) volume concentration is 3% to 15%, SO 2 Concentration is 50ppm~200ppm, NO concentration is 500ppm~1200ppm, NH 3 The concentration is 500ppm~1200ppm, O 2 The volume concentration is 2% ~ 5%, N 2 Make balance gas, air speed is 30,000h -1 ~200,000h -1 And under the condition of 200℃~270℃, its anti-H 2 O and SO 2 sex.

[0049] Catalyst activity evaluation method:

[0050] NO conversion rate (%) = 100% × (NO 入口浓度(ppm) –NO 出口浓度(ppm) ) / NO 入口浓度(ppm) ;

[0051] NO here 入口浓度(ppm) Corresponding to the NO concentration entering the catalyst bed, NO 出口浓度(ppm) Corresponds to the concentration of NO after passing through the catalyst bed.

[0052] Detection method: Use a fixed bed microreactor-nitrogen oxide analyzer detection system. The nitrogen oxide analyzer is a Swiss ECO PHYSICS model, which can analyze NO online 2 , N 2 O, NO. Data were collected after each temperature point was stabilized for 1 h.

[0053]Specific steps: Put the measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com