Low-cost low-cobalt single crystal ternary positive electrode material and preparation method thereof

A positive electrode material and ternary material technology, which is applied in the field of low-cost low-cobalt single crystal nickel-cobalt-manganese ternary positive electrode material preparation, can solve the problems of high sintering energy consumption, harsh sintering conditions, and environmental impact, and achieve simple preparation process, Low equipment requirements, reducing the effect of mixing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

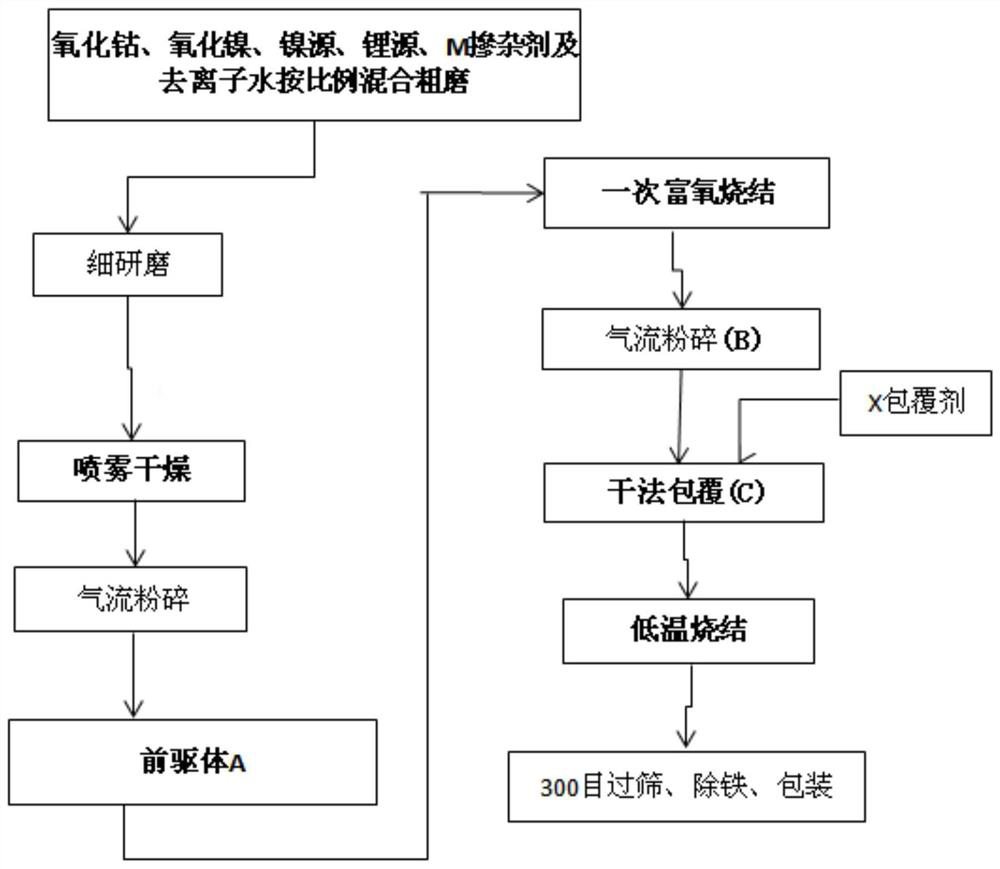

Method used

Image

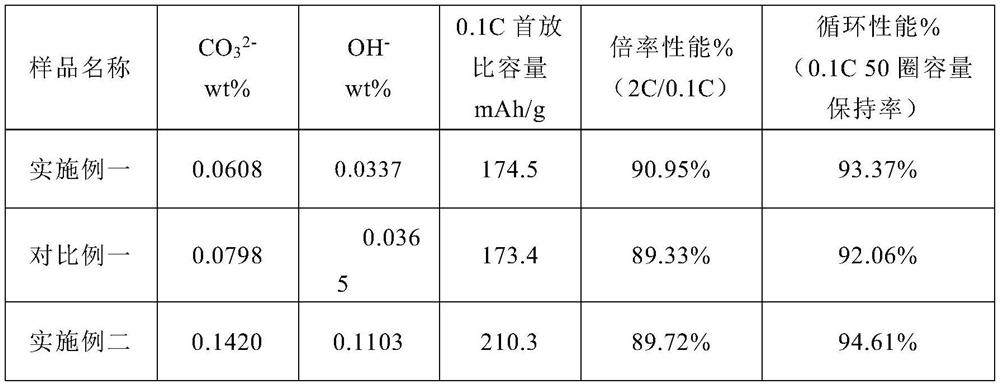

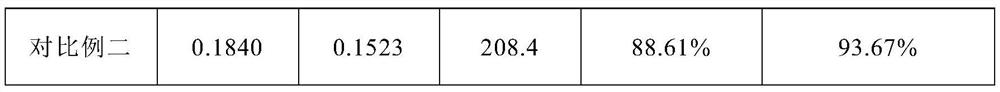

Examples

Embodiment 1

[0023] A low-cost LiNi 0.55 co 0.15 mn 0.3 o 2 A single crystal ternary cathode material and a preparation method thereof, comprising the following steps:

[0024] 1) Preparation of lithium-containing precursor A

[0025] First, weigh 0.05mol Co in turn according to the stoichiometric ratio 3 o 4 , 0.295mol MnO, 0.5mol NiO, 0.05mol nickel acetate, 1.03mol lithium carbonate, 0.02mol lithium dihydrogen phosphate and 0.001mol Y 2 o 3 , according to the order of easily soluble, difficult to tolerate, and insoluble, add them to the grinder for coarse and fine grinding, control the solid content of deionized water to 35%, grind until the particle size of the insoluble matter is ≤0.5 μm, and spray dry at 320 ° C to obtain the Lithium ternary precursor A.

[0026] 2) Preparation of highly dispersed single crystal ternary material B

[0027] The pulverized lithium-containing precursor A material was sintered once, sintered in air at 950°C for 12 hours, crushed, and passed thro...

Embodiment 2

[0033] A low-cost LiNi 0.83 co 0.12 mn 0.05 o 2 A single crystal ternary cathode material and a preparation method thereof, comprising the following steps:

[0034] (1) Preparation of lithium-containing precursor A

[0035] First, weigh 0.7molNiO, 0.04molCo in turn according to the stoichiometric ratio 3 o 4 , 0.05molMnO, 0.13mol nickel acetate, 1.02mol lithium hydroxide, 0.025 lithium dihydrogen phosphate and 0.002mol ZrO 2 , according to the order of easily soluble, difficult to tolerate, and insoluble, add it to the grinder for coarse and fine grinding, control the solid content of deionized water to 35%, grind until the particle size of the insoluble matter is ≤0.5 μm, and spray dry at 260°C to obtain the content Ternary precursor A. .

[0036] (2) Preparation of highly dispersed single crystal ternary material B

[0037] The pulverized lithium-containing precursor material A was sintered once, and sintered in an oxygen atmosphere at 830°C for 12 hours. After bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com