Preparation method of high-performance polyethylene fiber

A polyethylene fiber and polyethylene technology, which is applied in the direction of single-component polyolefin artificial filament, textile and papermaking, spinneret assembly, etc., can solve the problems of difficult entanglement, high viscosity, and shortening the dissolution of polyethylene time and other issues, to achieve the effect of solving the difficulty of dissolution, large stretching ratio, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

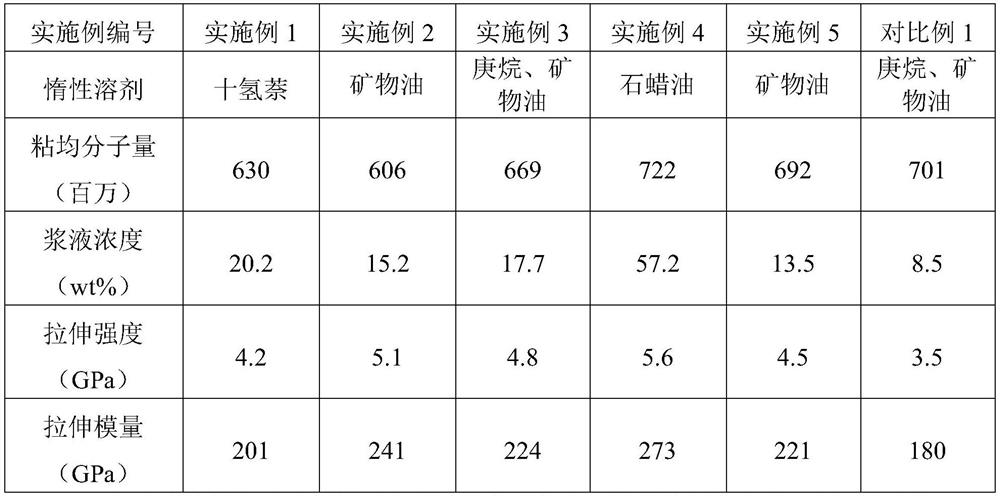

Examples

preparation example Construction

[0026] The preparation method of high performance polyethylene fiber of the present invention comprises the following steps:

[0027] The ethylene, inert solvent, polymerization catalyst system and hydrogen are introduced into the polymerization reactor, and the mixed liquid of polyethylene and inert solvent is prepared by slurry polymerization.

[0028] The bubble point of the inert solvent under standard pressure is greater than 100° C., which is alkanes, cycloalkanes, aromatics, or derivatives of alkanes / cycloalkanes / aromatics, or a mixture of any of them. Preferably, the bubble point is greater than 130°C, more preferably greater than 150°C, such as one of high boiling point mineral oil, paraffin oil, kerosene, and decahydronaphthalene.

[0029] The polymerization catalyst system used in the present invention consists of a solid catalyst containing transition metal components and a cocatalyst. The transition metal component includes a metal of Group IVB or VB of the perio...

Embodiment 1

[0052] Continuously introduce ethylene, inert solvent decahydronaphthalene (bubble point 191°C under standard pressure) into a polymerization reactor with a volume of 250L, and introduce a silica-supported titanium-magnesium catalyst together with triethylaluminum, and adopt slurry polymerization Continuous production of polyethylene. The feed rate of the catalyst was 2 g(Ti) / h, and the molar ratio of aluminum in the cocatalyst to titanium in the solid component was 200. The reaction temperature is 60° C., the reaction pressure is 8 bar, the residence time of the reactor is 2.5 h, and the stirring rate is 500 rpm.

[0053] The polyethylene and inert solvent mixture obtained by the reaction were continuously introduced into the dissolution tank, further raised to a dissolution temperature of 150°C under the protection of nitrogen, added decahydronaphthalene and 0.01wt% antioxidant 1010, stirred and dissolved for 5 minutes, and prepared A homogeneous polyethylene spinning solut...

Embodiment 2

[0056] Continuously introduce ethylene, inert solvent mineral oil (bubble point 367°C under standard pressure) into a polymerization reactor with a volume of 250L, and introduce silica-supported titanium-magnesium catalyst together with triethylaluminum, adopt continuous slurry polymerization Prepare polyethylene. The feed rate of the catalyst was 2 g(Ti) / h, and the molar ratio of aluminum in the cocatalyst to titanium in the solid component was 200. The reaction temperature is 60° C., the reaction pressure is 8 bar, the residence time of the reactor is 2.5 h, and the stirring rate is 500 rpm.

[0057] The polyethylene obtained by the reaction and the inert solvent mixture were continuously introduced into the dissolution tank, further raised to the dissolution temperature of 150°C under the protection of nitrogen, the same mineral oil and 0.01wt% antioxidant 1010 were added, and stirred for 5 minutes to dissolve. A homogeneous polyethylene spinning solution was obtained. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com