Preparation of iron-nitrogen co-doped porous carbon sphere electrocatalyst

An electrocatalyst and co-doping technology, applied in the fields of carbon materials and energy, can solve the problems of complex process and increased risk, and achieve the effect of wide application prospect, good sphericity and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

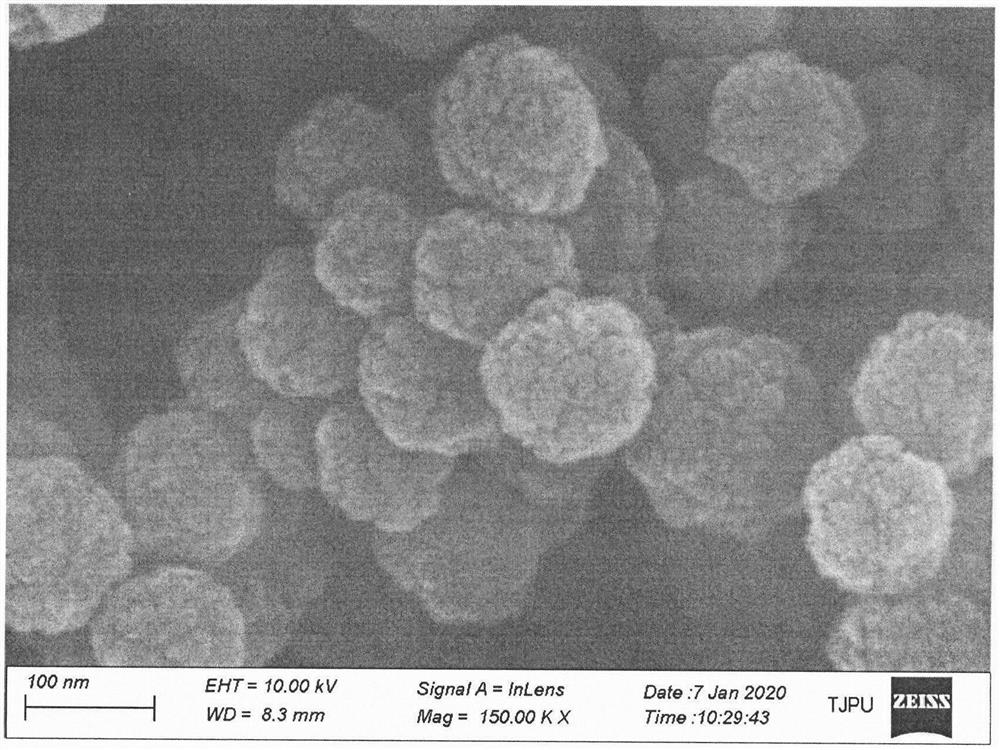

[0028] Preparation of iron-nitrogen co-doped spherical porous carbon materials:

[0029] Step 1) 1.07 g of 3,3'-diaminobenzidine was dissolved in 80 mL of ethanol, and the mixture was heated to 70°C.

[0030] Step 2) Add 10mL F127 ethanol solution (concentration is 10g / L), 10mL Fe(NO 3 ) 3 9H 2 O ethanol solution (0.025mol / L concentration) and 1.63g p-benzoquinone were stirred and refluxed at 70°C for 2 hours.

[0031] Step 3) After the reaction, the obtained brown product was filtered and washed with ethanol and water respectively until the solution was colorless, and dried at 120° C. to remove moisture to obtain polymer nanospheres.

[0032] Step 4) put the product of step 3) into the carbonization furnace, -1 The heating rate was increased to 900 °C. The atmosphere is a mixed gas of argon and ammonia, the flow rate ratio of which is 1:2 and kept for 2 hours, and the black powder target material is obtained after cooling down.

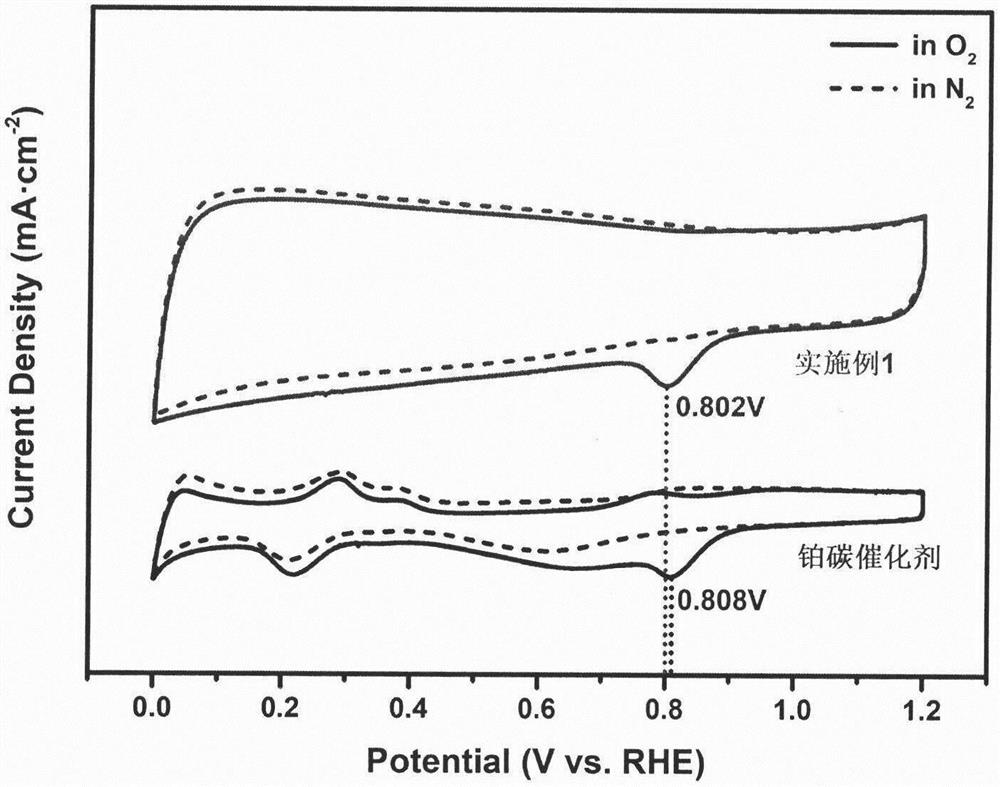

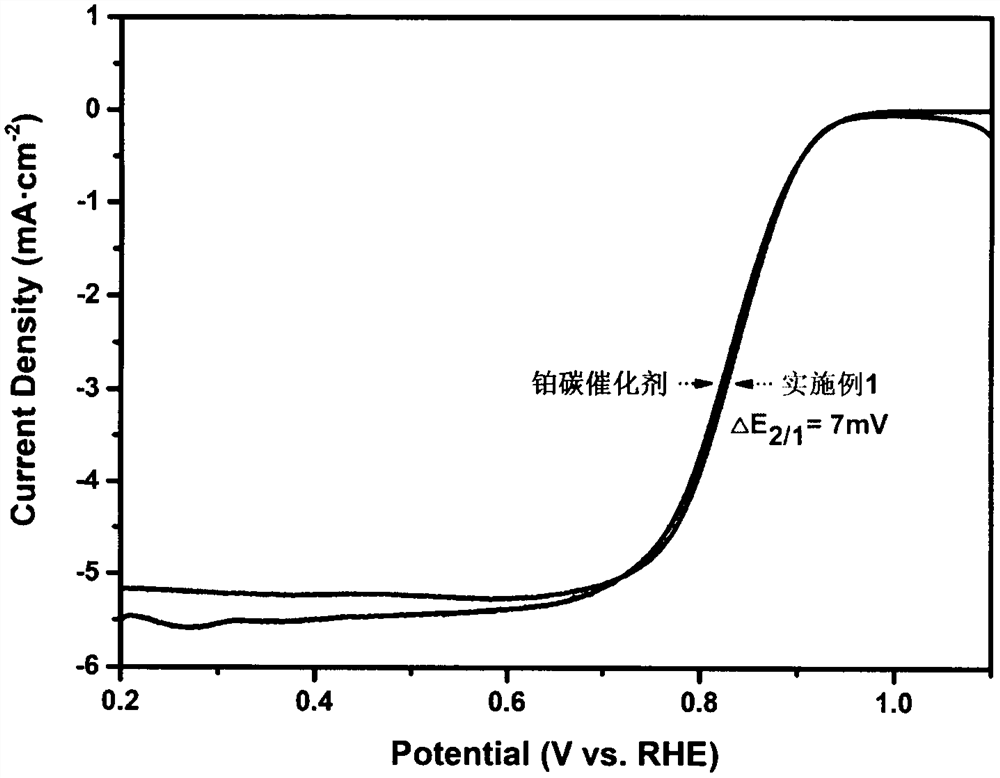

[0033] Electrocatalytic oxygen reduction...

Embodiment 2

[0039] Preparation of iron-nitrogen co-doped spherical porous carbon materials:

[0040] Step 1) 0.16 g of 3,3'-diaminobenzidine was dissolved in 60 mL of ethanol, and the mixture was heated to 90°C.

[0041] Step 2) Add 10mL F127 ethanol solution (concentration is 5g / L), 30mLFe(NO 3 ) 3 9H 2 O ethanol solution (0.0125 mol / L concentration) and 0.41 g p-benzoquinone were stirred and refluxed at 90° C. for 4 hours.

[0042] Step 3) After the reaction, the obtained brown product was filtered and washed with ethanol and water respectively until the solution was colorless, and dried at 80° C. to remove moisture to obtain polymer nanospheres.

[0043] Step 4) putting the product of step 3) into a carbonization furnace. at 2°C·min -1 The heating rate was increased to 800 °C. The atmosphere is a mixed gas of ammonia and argon with a flow rate ratio of 1:3 and kept for 3h. Obtain black powder target material after cooling down.

[0044] The electrocatalytic oxygen reduction tes...

Embodiment 3

[0046] Preparation of iron-nitrogen co-doped spherical porous carbon materials:

[0047] Step 1) 0.94 g of 3,3'-diaminobenzidine was dissolved in 70 mL of ethanol, and the mixture was heated to 80°C.

[0048] Step 2) Add 20mL F127 ethanol solution (concentration is 10g / L), 10mL Fe(NO 3 ) 3 9H 2 O ethanol solution (concentration: 0.0125mol / L) and 1.89g p-benzoquinone were stirred and refluxed for 3 hours at 80°C.

[0049] Step 3) After the reaction, the obtained brown product was filtered and washed with ethanol and water respectively until the solution was colorless, and dried at 100° C. to remove moisture to obtain polymer nanospheres.

[0050] Step 4) putting the product of step 3) into a carbonization furnace. at 3°C·min -1 The heating rate was increased to 1000 °C. The atmosphere is a mixed gas of ammonia and argon with a flow rate ratio of 1:1 and kept for 2h. Obtain black powder target material after cooling down.

[0051] The electrocatalytic oxygen reduction te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com