Phase-change microcapsule, preparation method thereof, intelligent temperature-control water-based drilling fluid and application

A technology of phase-change microcapsules and water-based drilling fluids, which is applied in the field of drilling fluids, can solve problems such as inability to effectively inhibit hydrate decomposition, and achieve good compatibility and environmental performance, excellent low-temperature rheology, and the effect of inhibiting hydrate decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

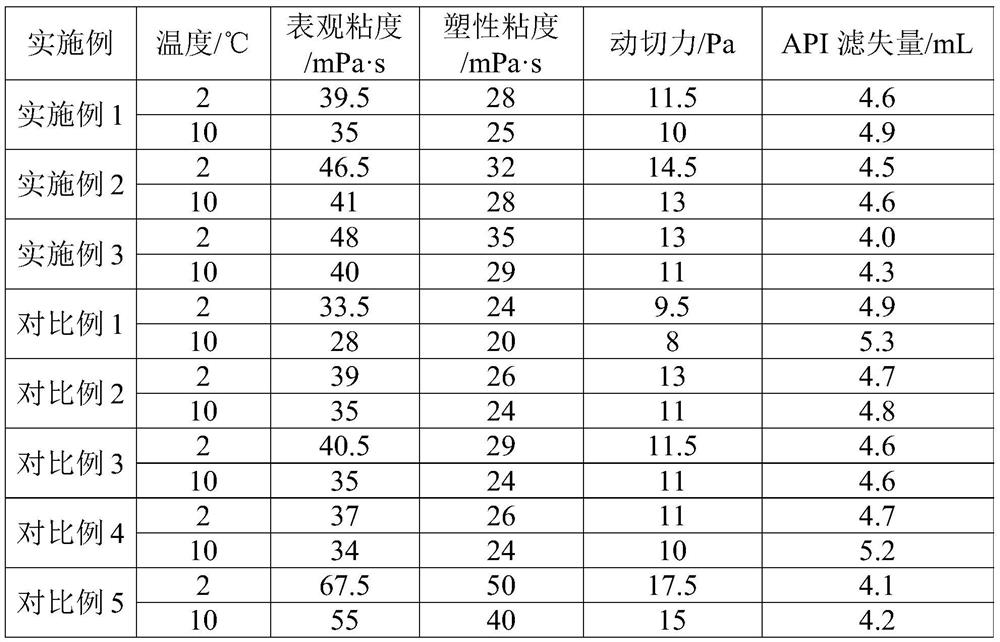

Examples

preparation example Construction

[0033] The second aspect of the present invention provides a kind of preparation method of aforementioned phase-change microcapsules, wherein, described preparation method comprises:

[0034] (1) first contacting the wall material, an optional wall material strengthening agent and water to obtain a wall material prepolymer;

[0035] (2) The core material is contacted with the water phase for the second time, and the water phase is a mixed solution of an emulsifier and water to form an oil / water emulsion;

[0036] (3) adding the wall material prepolymer dropwise into the oil / water emulsion for reaction, and then washing, suction filtering and drying to obtain phase change microcapsules.

[0037] According to the present invention, the water is preferably deionized water.

[0038] In the present invention, the preparation method of the phase change microcapsules comprises: stirring and mixing the wall material, an optional wall material strengthening agent and deionized water, ...

preparation example 1

[0057] This preparation example is to illustrate the preparation of phase change microcapsules.

[0058] Mix and stir 30g melamine, 60g formaldehyde solution (37%) and 33mL deionized water, adjust the pH value to 8 with triethanolamine, react in a constant temperature water bath at 75°C for 4 hours to obtain a wall material prepolymer; add 0.8g OP-10 to In 120mL of ionized water, add 28g of dodecyl alcohol and octanoic acid with a mass ratio of 50.6:49.4 dropwise into the water phase in a constant temperature water bath at 65°C, and stir for 1h at 1500r / min to form an oil / water emulsion; Add the wall material prepolymer solution dropwise to the emulsion at a rate of 0.5mL / min, adjust the pH value to 4 with citric acid, and react in a constant temperature water bath at 65°C for 5 hours; after the reaction, wash with ethanol and pump Filter and dry at 75°C for 24h.

[0059] Results The phase change microcapsule powder was prepared, marked as XW-1; and the average particle size ...

preparation example 2

[0061] This preparation example is to illustrate the preparation of phase change microcapsules.

[0062] 28g of melamine, 58g of formaldehyde solution (37%), 0.5g of trimanganese tetraoxide and 33g of deionized water were mixed and stirred, the pH value was adjusted to 8 with triethanolamine, and reacted in a constant temperature water bath at 80°C for 4 hours to obtain a wall material prepolymer; Add 1.0g of OP-10 into 120mL of deionized water, add 30g of dodecyl alcohol and decanol with a mass ratio of 1:1 dropwise into the water phase in a constant temperature water bath at 70°C, and stir at 1500r / min for 1h to form oil / water Emulsion: Add the wall material prepolymer solution dropwise into the emulsion at a rate of 0.4mL / min after the reaction, adjust the pH value to 3.5 with citric acid, and react in a constant temperature water bath at 70°C for 5 hours; After the reaction, wash with ethanol, filter with suction, and dry at 70°C for 24h.

[0063] Results The phase change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com