Method for improving surface loading capacity of rare earth fluoride nano material

A technology of rare earth fluorides and nanomaterials, applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve the problem of difficult to achieve particle size and uniform particle preparation, large changes in particle size of rare earth fluoride nanoparticles, adverse biological Problems such as metabolism and excretion can be improved to achieve the effect of improving the overall fluorescence intensity, uniform properties, and enhanced fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

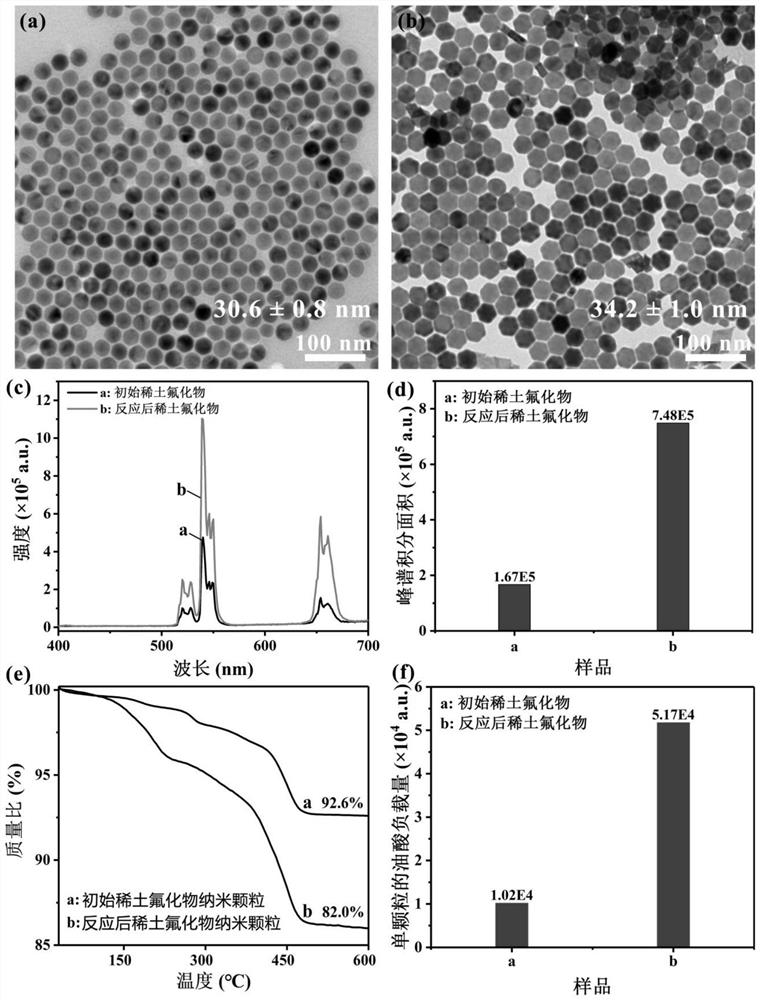

[0033] Weigh 1mmol lutetium oxide (Lu 2 o 3 ) was placed in a three-necked flask, and 5 mL of deionized water and 5 mL of trifluoroacetic acid (CF 3 COOH), stirred and heated to 98°C, after the rare earth oxide (lutetium oxide) was fully dissolved, the solution was evaporated to dryness (removing water and excess trifluoroacetic acid), and then cooled to room temperature to obtain lutetium trifluoroacetate (Lu( CF 3 COO) 3 ) crystallized for subsequent reactions. The 1mmol particle size is about 30nm hexagonal phase rare earth fluoride nanocrystalline NaYF 4 : Yb, Er2% are dispersed in 10mL cyclohexane, then 2mL of this solution, 10mL oleic acid (OA) and 10mL1-octadecene (ODE) are added in the above-mentioned three-necked flask containing trifluoroacetate, under nitrogen ( N 2 ) flow to 100°C, and stirred for 15 minutes at a constant temperature to remove cyclohexane and moisture in the system; then rapidly raised to 300°C, stopped heating after 2 hours of constant tempe...

Embodiment 2

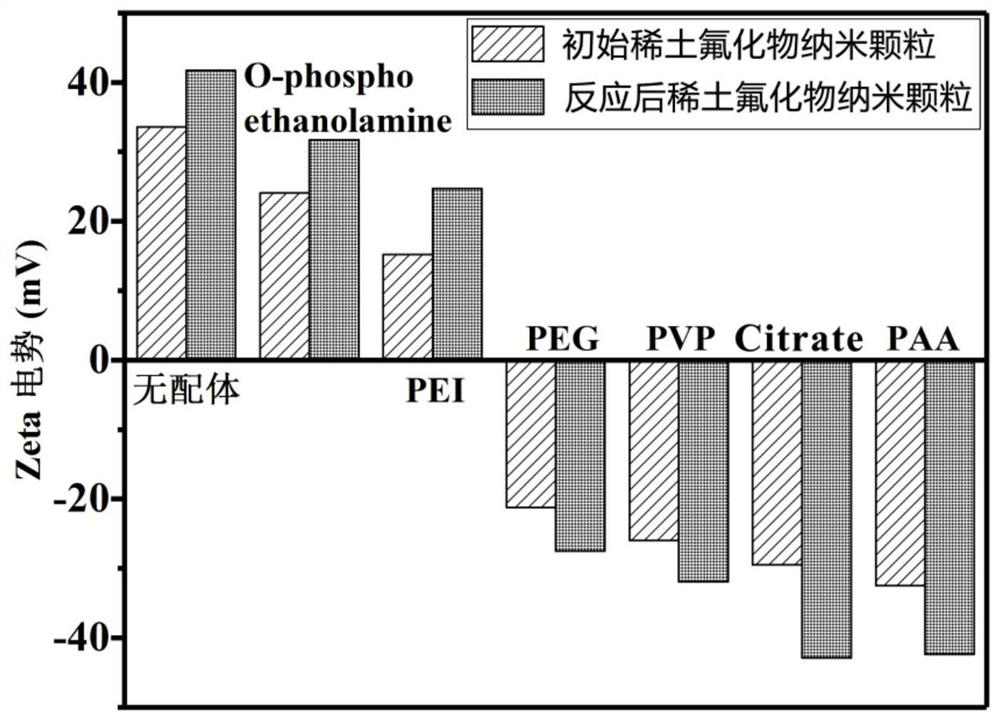

[0036] Utilize the technical method described in embodiment 1 to obtain reaction product, the rare earth fluoride nanoparticle before and after the reaction is respectively dispersed in cyclohexane, then removes the oleic acid ligand on the nanoparticle surface with pH=1 hydrochloric acid solution (referring to Bogdan , N.; Vetrone, F.; Ozin, G.A.; Capobianco, J.A., Synthesis of Ligand-Free ColloidallyStable Water Dispersible Brightly Luminescent Lanthanide-Doped Upconverting Nanoparticles. Nano Lett. 2011, 11(2), 835-840.). At this time, the nanoparticles enter the water layer from the cyclohexane layer, and then the solution is transferred to a centrifuge tube and centrifuged at a speed of 15,000 rpm for 30 minutes to obtain the rare earth fluoride nanoparticles without ligands on the surface. Rare earth fluoride nanoparticles without oleic acid ligand before and after the reaction were redispersed in ionized water, and then phosphoethanolamine (O-phosphoethanolamine), polyet...

Embodiment 3

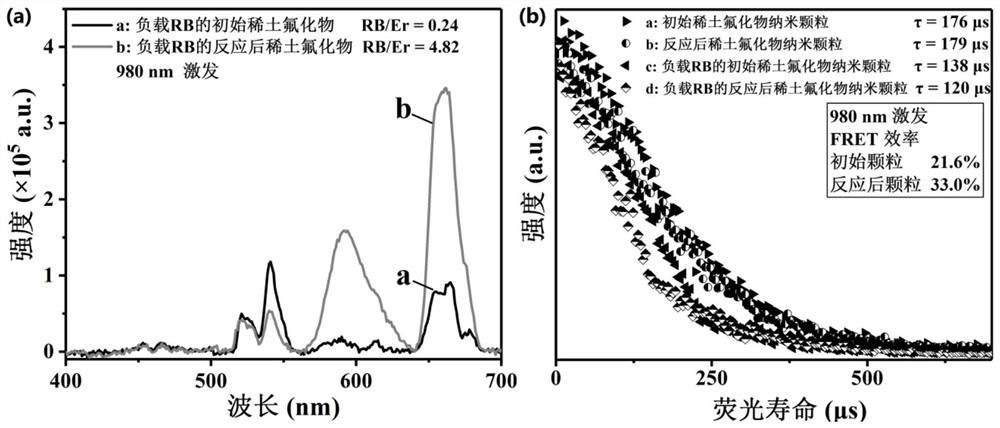

[0039] Utilize the technical method described in the embodiment 1 to obtain the reaction product, the rare earth fluoride nanoparticles before and after the reaction are respectively dispersed in cyclohexane, and then the oleic acid ligand on the surface of the nanoparticles is removed with pH=1 hydrochloric acid solution (same as the implementation Example 2), at this time, the nanoparticles enter the water layer from the cyclohexane layer, and then the solution is transferred to a centrifuge tube and centrifuged at a speed of 15,000 rpm for 30 minutes to obtain rare earth fluoride nanoparticles without ligands on the surface. Then take the same mass concentration of rare earth fluoride nanomaterials without ligands on the surface (rare earth fluoride nanoparticles before and after the reaction after deoleic acid treatment) and Rose Bengal (Rose Bengal, RB) organic dyes to react (refer to Muhr, V.; Würth, C.; Kraft, M.; Buchner, M.; Baeumner, A.J.; Resonance Energy Transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com