Lactobacillus casei for improving silage quality of paper mulberry and application of lactobacillus casei

A technology of Lactobacillus casei and paper mulberry, which is applied in the field of Lactobacillus casei, can solve the problems of not being able to improve the effect of paper mulberry silage, the effect of paper mulberry silage is not good, and the number of lactic acid bacteria is small, so as to improve the quality of mulberry silage and increase the nutritional value And palatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The screening of embodiment 1 mulberry silage special strain

[0024] 1) Liquid enrichment: select a mulberry silage sample with a pH of 4.0-4.5, take 3-5g of the sample and put it into 100mL of sterilized MRS liquid medium, and culture it statically in a 37°C incubator for 36h-48h. Among them, the MRS liquid medium is composed of 2% sucrose, 1% peptone, 1% beef extract, 0.5% yeast extract powder, 0.5% sodium acetate, 0.2% ammonium citrate, 0.2% K 2 HPO 4 , 0.05% MgSO 4 ·7H 2 O, 0.02% MnSO 4 4H 2 O, 0.1% Tween, and the balance are composed of water, and the pH is adjusted to 6.2-6.4.

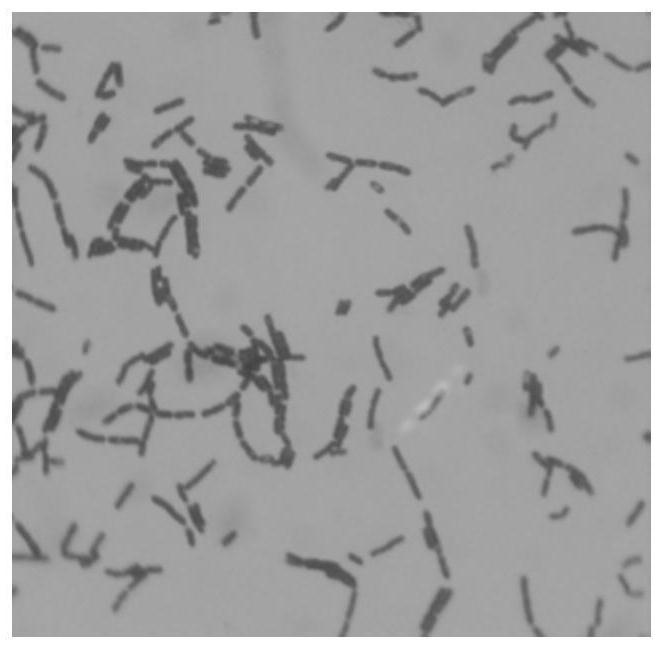

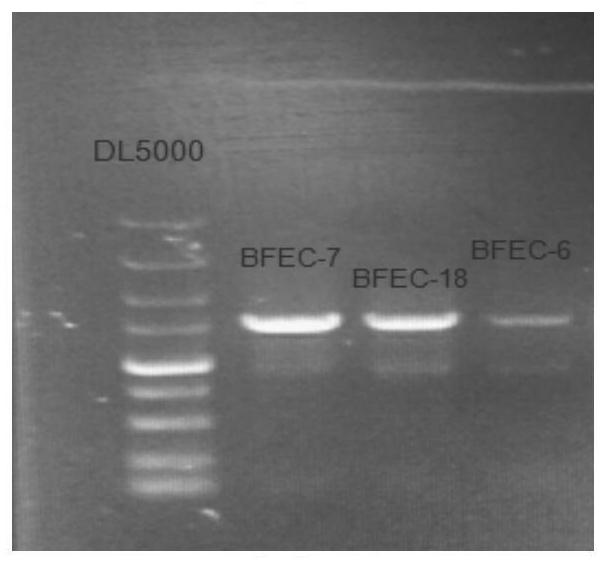

[0025] 2) Solid culture: draw 1mL of the above-mentioned liquid-enriched bacterial solution and carry out 10 days with normal saline. -4 、10 -5 、10 -6 Gradient dilution, draw 200 μL of the diluted solution and evenly spread it on the MRS solid medium, culture it statically in a 37°C incubator for 36h-48h, pick the colony with good shape and growth, and further streak and purify it...

Embodiment 2

[0039] The probiotic property of embodiment 2 Lactobacillus casei of the present invention

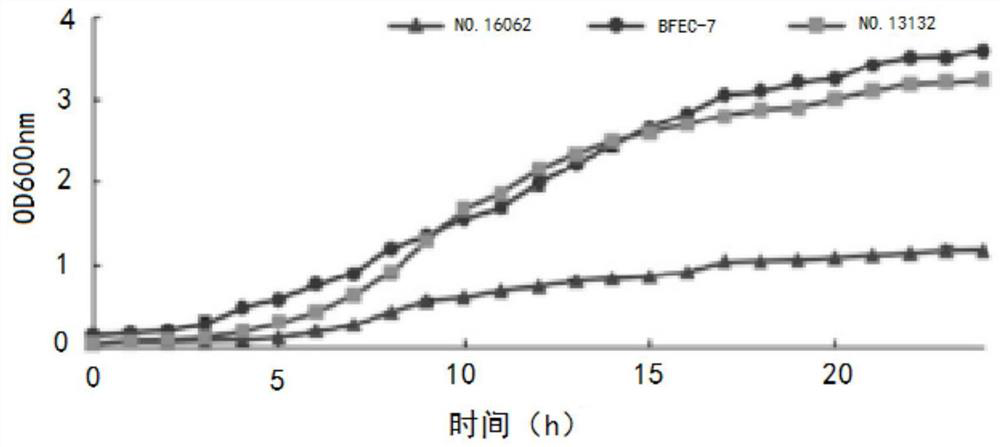

[0040] Inoculate the isolated Lactobacillus casei CGMCC NO.20432 (BFEC-7), Lactobacillus plantarum of CGMCC NO.13132, and Enterococcus faecalis of CGMCC NO.16062 in MRS liquid medium, and culture them statically in a 37°C incubator , from the fourth hour, use a microplate reader to detect the absorbance every hour, and record the absorbance value to evaluate the growth rate of the strain. For experimental data, see image 3 . Among them, Lactobacillus plantarum numbered CGMCC NO.13132 and Enterococcus faecalis numbered CGMCC No.16062 have been described in "A General Composite Fermentation Agent for Livestock and Poultry and Its Preparation and Application" with application number 201911203375.7. I won't go into details here. The bacterial strains selected in this application are three bacterial strains finally selected and determined through a large number of experimental verificat...

Embodiment 3

[0053] The silage experiment of embodiment 3 mulberry silage special bacterial agent

[0054] The culture fluid of bacterial strain CGMCC NO.13132, NO.20432, NO.16062 (wherein the bacterium concentration in CGMCC NO.13132 and NO.20432 bacterial fluid is respectively 10 8 CFU / mL, the bacterial concentration in NO.16062 bacterial solution is 10 7 CFU / mL) at a volume ratio of 0.5:2:0.5 to make a compound silage agent, cut the fresh mulberry branches and leaves into 1-2cm lengths, and add (mL / g) to the fresh mulberry branches and leaves Add compound silage agent for 1%, that is, add compound silage agent 1.0mL in 100g of fresh mulberry branches and leaves, and add molasses of 2%-5% of silage branches and leaves quality. After mixing well, put it in a breathing bag for compaction and sealing, and silage at 25°C-35°C for 40-50 days, and take silage on the 0th, 5th, 10th, 20th, 30th, and 40th day of the silage experiment, and use a pH meter to detect The pH value was determined by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com