Method for producing alpha-cyanoacrylate adhesive by continuous feeding

An adhesive and ethyl cyanoacetate technology, which is applied in the field of continuous feed production of α-cyanoacrylate adhesives, can solve the problem of reducing product yield and production efficiency, reducing the initial concentration of reactants, and slowing down the polycondensation reaction. speed and other issues, to achieve the effect of reducing the temperature range of depolymerization, reducing energy consumption, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

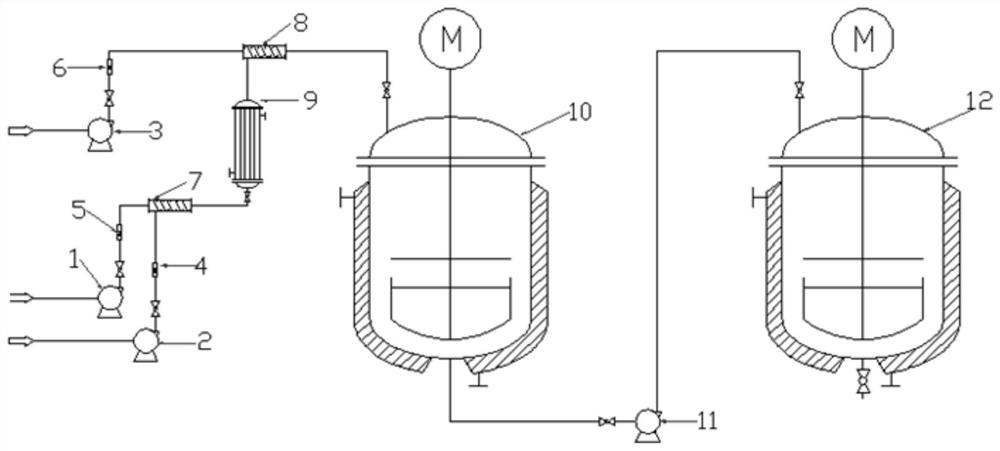

[0036] A device for producing α-cyanoacrylate adhesive with continuous feed, the structure is as follows figure 1 Shown, comprise first mixer 7, second mixer 8, preheater 9, pre-reactor 10 and polycondensation reactor 12, first mixer 7 is connected with ethyl cyanoacetate feeding pump 1 and organic solvent feed Feed pump 2, the second mixer 8 is connected with the second feed pump 3, the second feed pump 3 is used to input formaldehyde, basic catalyst, the first mixer 7 is connected with the preheater 9, and the preheater 9 is connected with the The second feed pump 3 is commonly connected with the second mixer 8, and the second mixer 8, the pre-reactor 10 and the polycondensation reactor 12 are connected in sequence. An intermediate feed pump 11 is arranged between the pre-reactor 10 and the polycondensation reactor 12 . A rotameter is arranged between the first mixer 7 and the ethyl cyanoacetate feed pump 1 and the organic solvent feed pump 2 , and a rotameter 6 is arranged...

Embodiment 2

[0038] Utilize the device of embodiment 1 to carry out the method for continuous feed production α-cyanoacrylate adhesive, comprise steps as follows:

[0039] Ethyl cyanoacetate and 1,2-dichloroethane enter the first mixer 7 from the feed pump at a flow rate of 1530kg / h and 1200kg / h to mix evenly, then preheat through the heat exchanger 9, and then mix with the following The flow rate of 1050kg / h enters the formaldehyde and hexahydropyridine through the second feed pump 3 into the second mixer 8, enters the pre-reactor 10 for preliminary polycondensation reaction, and finally enters the polycondensation reactor 12 through the intermediate feed pump 11 Carry out sufficient polycondensation reaction to form α-cyanoacrylate ethyl ester prepolymer; then use 1,2-dichloroethane azeotropic dehydration; then add 10kg inhibitor and 450kg plasticizer, under 3mmHg vacuum condition High-temperature depolymerization, complete cracking at 160-180°C and collect the crude product; finally, th...

Embodiment 3

[0042] Utilize the device of embodiment 1 to carry out the method for continuous feed production α-cyanoacrylate adhesive, comprise steps as follows:

[0043] Ethyl cyanoacetate and 1,2-dichloroethane are respectively fed into the first mixer 7 by the feed pump at a flow rate of 1360kg / h and 1060kg / h, and then preheated by the heat exchanger 9, and then mixed with 930kg The formaldehyde and hexahydropyridine entered by the flow rate of / h through the second feed pump 3 are mixed uniformly in the second mixer 8, enter the pre-reactor 10 for preliminary polycondensation reaction, and finally enter the polycondensation reactor 12 through the intermediate feed pump 11 Carry out sufficient polycondensation reaction in , form α-ethyl cyanoacrylate prepolymer, carry out dehydration, depolymerization, refining by the same condition of embodiment 2, obtain the monomer that purity is 99.9%, and calculated mass yield is 82% . Under these conditions, the molecular weight of the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com