Graphene-like carbon-coated silicon/carbon/graphene composite material, preparation method thereof and negative electrode material

A technology of graphene carbon and composite materials, applied in the preparation/purification of carbon, graphene, carbon compounds, etc., can solve the problems of poor cycle stability of Si/C composite materials, achieve large-scale mass production and improve cycle stability Sexuality and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]In another exemplary embodiment of the present application, a method for preparing the aforementioned graphene-like carbon-coated silicon / carbon / graphene composite material is provided. The preparation method includes: Step S1: , Phenolic resin solution, graphene slurry and graphite are mixed to obtain a mixture; step S2, the mixture is dried to obtain dried composite material powder; step S3, in an inert atmosphere, the dried composite material powder, carbon source and The foaming agent is mixed and heated to obtain a carbon-coated composite material; and in step S4, the carbon-coated composite material is calcined to obtain a graphene-like carbon-coated silicon / carbon / graphene composite material.

[0025]The carbon source is first melted into a liquid slurry during heating, and the liquid slurry will gradually polymerize to obtain macromolecular polymers and wrap them on the surface of the composite powder. The chemical gas released by the foaming agent will blow out the macro...

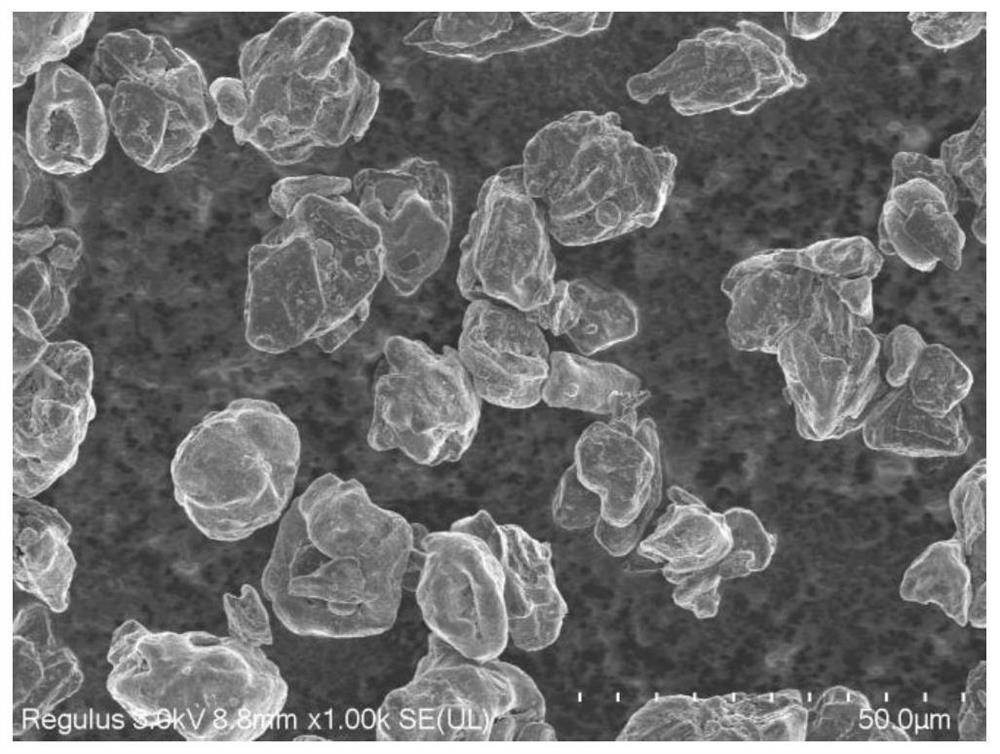

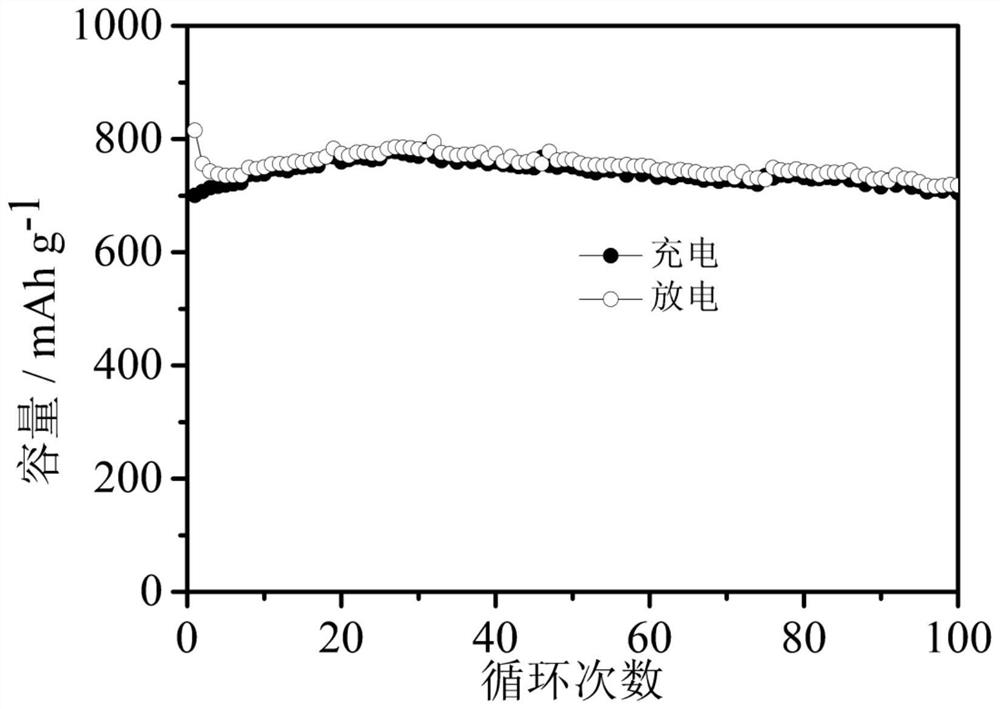

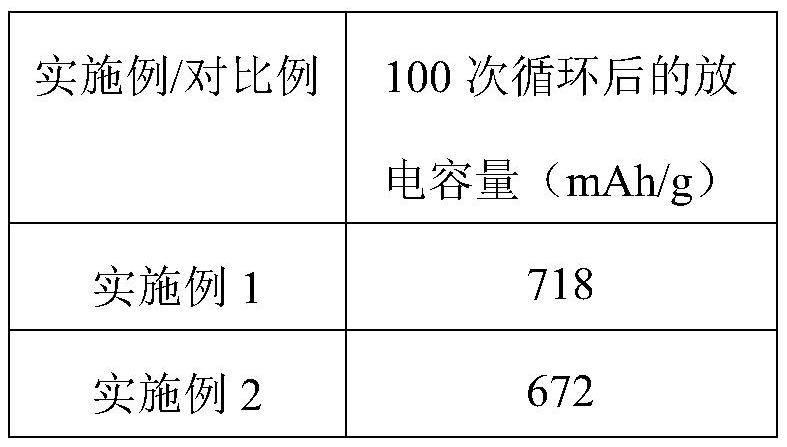

Embodiment 1

[0040]Weigh 400g of silicon powder with a particle size of 100μm and mill it with a zirconia ball with a particle size of 0.1mm. The mass ratio of the balls is 1.6:1, the solvent is ethanol, and the mixed is evenly mixed. The solution was added to the nano-sand mill, and ball milled at a ball milling speed of 2000 rpm / min for 5 hours to obtain a nano silicon solution with a mass concentration of 0.13 g / mL.

[0041]Mix 3000mL of nano silicon solution with 500mL of phenolic resin ethanol solution with a mass concentration of 0.2g / mL, 500mL of graphene slurry with a mass concentration of 0.03g / mL, 4485g of graphite, stir until uniform, and then use a high-speed grinding and dispersing machine The mixture was ground and dispersed for 2 hours at a speed of 2000 rpm / min to obtain a mixture. The mixture is spray-dried at 160° C. for 0.5 h to obtain a dried composite material powder. The dried composite material powder includes 8% nano silicon, 2% phenolic resin, 0.1% graphene, and 89.9% graph...

Embodiment 2

[0045]The difference between Example 2 and Example 1 is that the mass ratio of composite material powder, glucose and ammonium chloride after drying is 95:5:5 to obtain a graphene-like carbon coated silicon / carbon / graphene composite material. The diameter (D50) is 23 μm, and includes 1% graphene-like carbon coating layer, 10% silicon, 88.7% carbon, and 0.3% graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com