Coal-fired power plant desulfurizing wastewater zero-discharge treatment process and equipment

A technology for desulfurization wastewater and coal-fired power plants, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. many problems, to achieve the effect of saving the cost of softening agent, short process flow and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

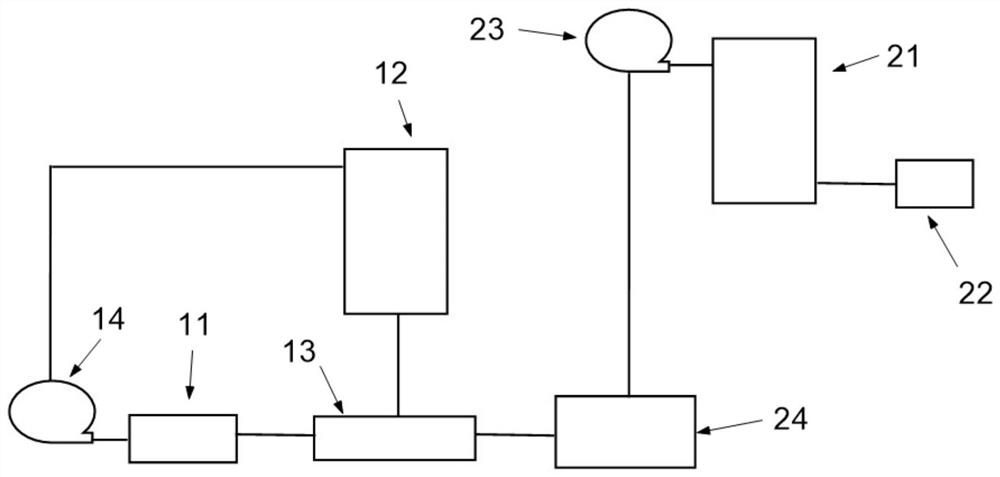

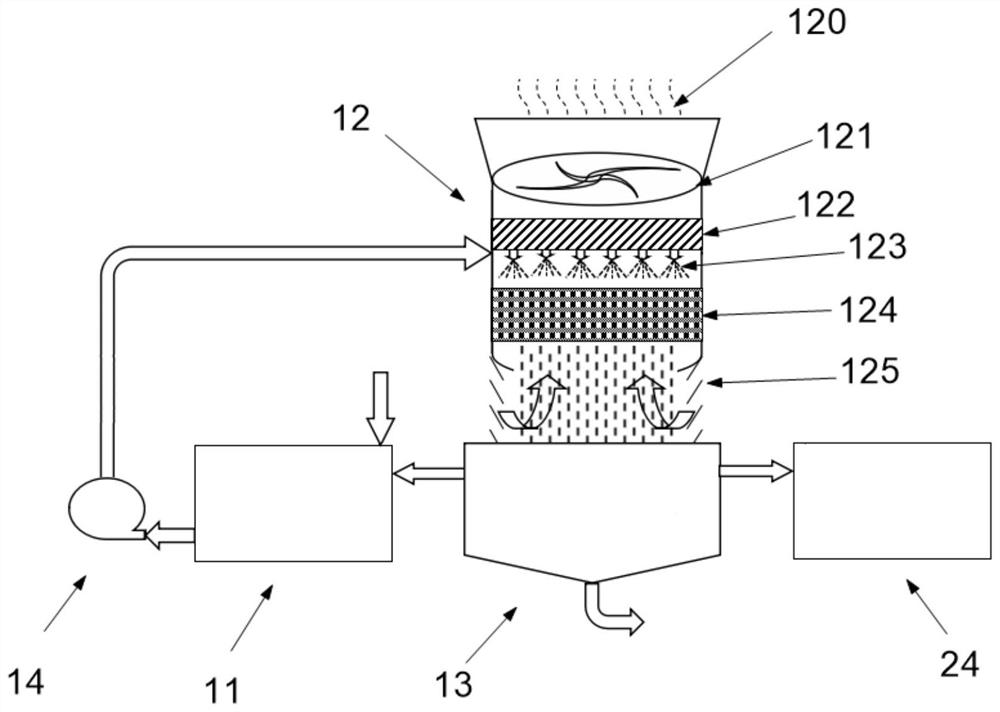

[0071] This embodiment provides a zero-discharge treatment equipment and treatment process for desulfurization wastewater from a coal-fired power plant. The treatment equipment includes a waste water evaporation concentration unit and a waste water spray drying unit; its structural diagram is as follows figure 1 As shown, the solid line segment in the figure represents the pipeline, figure 1 Only the pipes connecting each device in the waste water evaporation concentration unit and the waste water spray drying unit are drawn. The structure of the wastewater evaporation concentration unit is as follows: figure 2 As shown, in order to clearly show the connection of the waste water evaporative concentration unit and the waste water spray drying unit, figure 2 Buffer tank 24 (belonging to the wastewater spray drying unit) is also drawn.

[0072] Such as figure 1 with figure 2 As shown, the wastewater evaporation and concentration unit includes a wastewater regulating tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com