Preparation method of toughened BNNSs/SiC ceramic matrix composite material

A composite material and ceramic-based technology, which is applied in the field of preparation of toughened BNNSs/SiC ceramic-based composite materials, can solve the problems affecting the application effect and achieve the effect of improving the dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a toughened BNNSs / SiC ceramic matrix composite material, comprising the following steps:

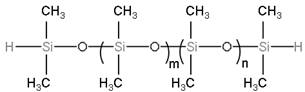

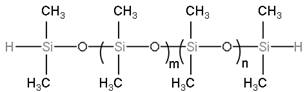

[0029] S1. Weigh 100mg of hexagonal boron nitride and put it into an 80ml ball milling jar, then put 2g of 5-aminovaleric acid and 35ml of deionized water into the ball milling jar, seal the ball milling jar, and perform mechanical ball milling at a speed of 1200rpm for 16h, then suction filter, Washing with water and drying to obtain functionalized boron nitride nanosheets; mix vinyl tris (β-methoxyethoxy) silane and glycidyl methacrylate evenly, and then add to the hydrogen-terminated oligomerization process containing platinum catalyst React in siloxane at 25°C for 120min to obtain a silane coupling agent containing an epoxy group; dissolve the obtained silane coupling agent containing an epoxy group in DMF, and then add the functionalized hexagonal boron nitride nanometer slices, ultrasonically stirred in a water bath, the stirring rate was 200rpm, and t...

Embodiment 2

[0036] A method for preparing a toughened BNNSs / SiC ceramic matrix composite material, comprising the following steps:

[0037] S1. Weigh 140mg of hexagonal boron nitride and put it into an 80ml ball milling jar, then put 2g of 5-aminovaleric acid and 50ml of deionized water into the ball milling jar, seal the ball milling jar, and perform mechanical ball milling at a speed of 900rpm for 18h, then suction filter. Washing with water and drying to obtain functionalized boron nitride nanosheets; dissolving the silane coupling agent containing epoxy groups (the preparation method is the same as in Example 1) in DMF, then adding functionalized hexagonal boron nitride nanosheets, and ultrasonically stirring in a water bath , the stirring rate is 250rpm, and the grafting reaction is carried out at 100°C for 10h. After the grafting reaction is completed, it is suction filtered, washed with water, and dried to obtain a boron nitride nanosheet grafted silane coupling agent product, which...

Embodiment 3

[0042] A method for preparing a toughened BNNSs / SiC ceramic matrix composite material, comprising the following steps:

[0043] S1. Weigh 120mg of hexagonal boron nitride and put it into an 80ml ball milling jar, then put 2g of 5-aminovaleric acid and 40ml of deionized water into the ball milling jar, seal the ball milling jar, and perform mechanical ball milling at a speed of 900rpm for 14h, then suction filter, Washing with water and drying to obtain functionalized boron nitride nanosheets; mix vinyl tris (β-methoxyethoxy) silane and glycidyl methacrylate evenly, and then add to the hydrogen-terminated oligomerization process containing platinum catalyst React in siloxane at 20°C for 100 minutes to obtain a silane coupling agent containing epoxy groups; dissolve the obtained silane coupling agent containing epoxy groups in DMF, and then add functionalized hexagonal boron nitride nanosheets, Ultrasonic stirring in a water bath, the stirring rate is 250rpm, and the grafting re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com