Preservative film containing peanut coat procyanidine inclusion compound and preparation method thereof

A technology of proanthocyanidins and peanut coating, which is applied in the field of fresh-keeping film containing peanut chlamydia procyanidin inclusion complex and its preparation field, can solve the problems of easy degradation, poor stability and the like, and achieves low price, good tensile elongation and good performance. Effects of Membrane Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

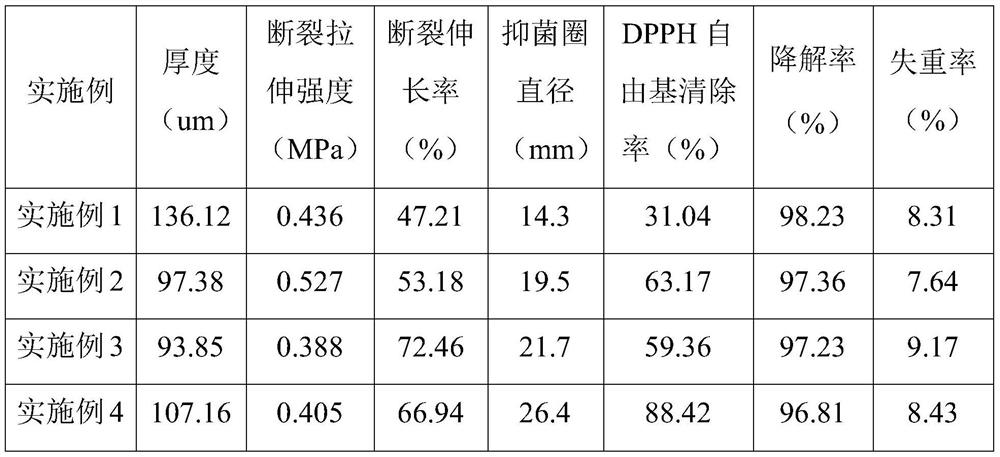

Examples

preparation example Construction

[0018] A preparation method for a preservative film containing proanthocyanidin clathrates of peanuts, comprising the following steps:

[0019] Step 1) Preparation of membrane solution: Add 2 to 6 parts of peanut proanthocyanidin inclusion complex, 0.6 to 1.2 parts of corn starch, 1.2 to 1.6 parts of gelatin, and 0.4 to 0.8 parts of chitosan based on 100 parts by total mass In deionized water, add deionized water and peanut proanthocyanidin inclusion compound, corn starch, gelatin, chitosan, and glycerin to make up 100 parts, put it into a magnetic stirrer, and perform magnetic stirring at a speed of 200r / min. The time is 20-30 minutes, after fully mixing, add 1.6-2 parts of glycerin, and continue to stir magnetically at a speed of 200r / min for 10 minutes, and stir evenly;

[0020] Step 2) Preparation of degradable plastic wrap: Take out the sample solution and place it in an ultrasonic water bath, degas it for 10 minutes at a power of 200W, pour the degassed solution into a s...

Embodiment 1

[0023] Based on the total mass of 100 parts, add 2 parts of peanut clothing proanthocyanidin inclusion compound, 1.2 parts of cornstarch, 1.4 parts of gelatin, and 0.6 parts of chitosan into deionized water, and add the parts of deionized water and peanut clothing proanthocyanidin Add 100 parts of clathrate, cornstarch, gelatin, chitosan, and glycerin, put them into a magnetic stirrer, and stir magnetically at a speed of 200r / min for 20-30 minutes, mix well and then add glycerin 1.6 parts, continue to stir magnetically at a speed of 200r / min for 10min, and stir evenly;

[0024] Take out the sample solution and place it in an ultrasonic water bath, degas it for 10 minutes at a power of 200W, pour the degassed solution into a square organic resin film-forming vessel with a bottom surface of 10cm×10cm, and place it in an oven for 70 Dry at ℃ for 2.5h, and remove the film after cooling to room temperature.

Embodiment 2

[0026] Based on the total mass of 100 parts, add 4 parts of peanut proanthocyanidin inclusion compound, 0.8 part of cornstarch, 1.2 parts of gelatin, and 0.8 part of chitosan into deionized water. Add 100 parts of clathrate, cornstarch, gelatin, chitosan, and glycerin, put them into a magnetic stirrer, and stir magnetically at a speed of 200r / min for 20-30 minutes, mix well and then add glycerin 2 parts, continue to carry out magnetic stirring under the condition of rotating speed of 200r / min, the time is 10min, and stir evenly;

[0027] Take out the sample solution and place it in an ultrasonic water bath, degas it for 10 minutes at a power of 200W, pour the degassed solution into a square organic resin film-forming vessel with a bottom surface of 10cm×10cm, and place it in an oven for 70 Dry at ℃ for 2.5h, and remove the film after cooling to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com