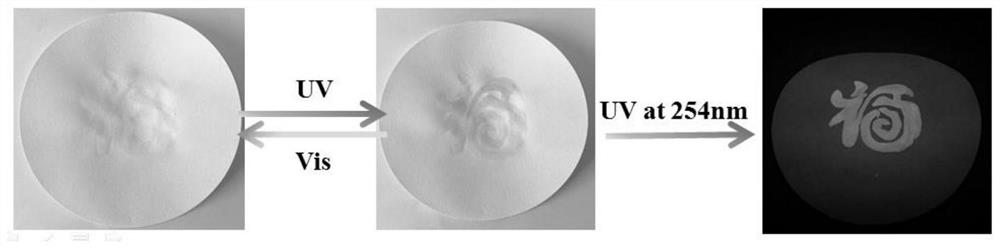

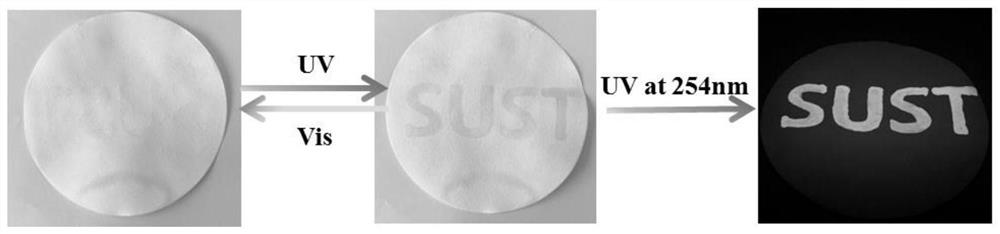

Photochromic ink-jet printable water-based fluorescent ink and preparation method thereof

An inkjet printing and photochromic technology, used in inks, household appliances, applications, etc., can solve the problems of narrow emission spectrum and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of the photochromic ink-jet printing water-based fluorescent ink based on lanthanide metal organic framework of the present invention, specifically comprises the following steps:

[0031] (1) Preparation of lanthanide metal organic frameworks;

[0032] 0.1 mmol lanthanide metal compound (specifically LnCl 3 ·6H 2 O, Ln=Eu 3+ or Tb 3+ ), 0.1mmol trimesic acid (H 3 BTC), 10-15ml N,N-dimethylformamide and 5-10ml deionized water were added to the beaker and stirred evenly. Transfer the uniformly mixed mixture to a reaction kettle lined with polytetrafluoroethylene, and heat it in a muffle furnace at 80-120°C for 12-24h, which has a good heat preservation effect and is conducive to the formation of lanthanide metal organic frameworks. The formation of the appearance, and it is also convenient to adjust the cooling rate. After the reaction, the reaction kettle was slowly cooled to room temperature at a temperature of 5-10 °C / h. The precipit...

Embodiment 1

[0041] A kind of preparation method of photochromic inkjet printing water-based fluorescent ink of the present invention specifically comprises the following steps:

[0042] (1) Preparation of lanthanide metal organic frameworks:

[0043] LnCl 3 ·6H 2 O (0.1mmol Ln 3+ =Eu 3+ ), trimesic acid (H 3 BTC 0.1mmol), N,N-dimethylformamide (10ml) and deionized water (5ml) were added into the beaker and stirred evenly for 1h. The homogeneously mixed mixture above was transferred to a Teflon-lined autoclave and heated at 80 °C for 12 hours. The reaction vessel was cooled slowly to room temperature at a temperature of 5 °C / h. The reaction solution generated above was separated by filtration, washed successively with N,N-dimethylformamide and deionized water, and vacuum-dried at 50°C for 12 hours to obtain white needle-like crystals, which were stored in a desiccator.

[0044] (2) Adsorption of spiropyrans by lanthanide metal organic frameworks:

[0045] 60 mg of the above-mention...

Embodiment 2

[0051] A kind of preparation method of photochromic inkjet printing water-based fluorescent ink of the present invention specifically comprises the following steps:

[0052] (1) Preparation of lanthanide metal organic frameworks:

[0053] LnCl 3 ·6H 2 O (0.1mmol Ln 3+ =Tb 3+ ), trimesic acid (H 3 BTC 0.1mmol), N,N-dimethylformamide (12ml) and deionized water (8ml) were added into the beaker and stirred evenly for 1h. The homogeneously mixed samples above were transferred to a Teflon-lined autoclave and heated at 100 °C for 20 h. The reaction vessel was cooled slowly to room temperature at a temperature of 7 °C / h. The reaction solution generated above was separated by filtration, washed successively with N,N-dimethylformamide and deionized water, and dried in vacuum at 50° C. for 12 hours to obtain white needle-like crystals. Collected samples were stored in a desiccator.

[0054] (2) Adsorption of spiropyrans by lanthanide metal organic frameworks:

[0055] The above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com