Method for comprehensively recovering niobium, rare earth and titanium from polymetallic ore containing iron, niobium and rare earth

A polymetallic ore and rare earth concentrate technology, applied in the field of niobium resource utilization, can solve problems such as low grade, difficult and efficient enrichment of niobium ore phases, and failure to meet the production standards of high-grade ferroniobium, achieving remarkable economic and social benefits, The effect of strong process operability and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for comprehensively recovering niobium, rare earth and titanium from polymetallic ores containing iron, niobium and rare earth, comprising the steps of:

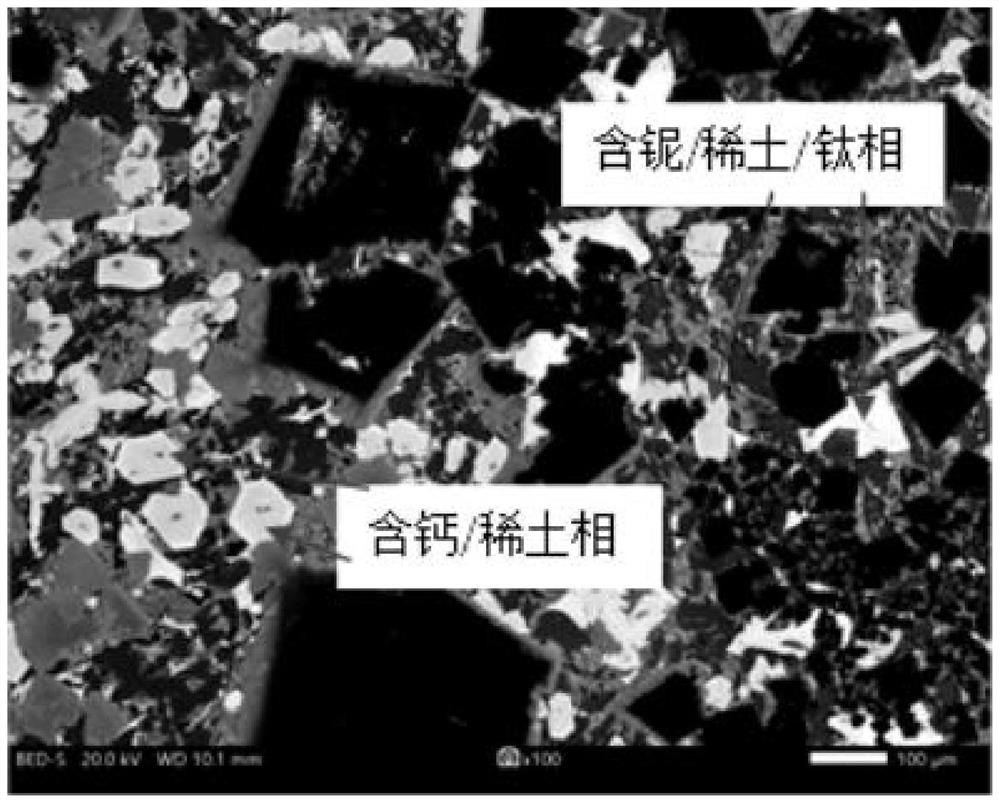

[0041] (1) Iron, niobium, rare earth polymetallic ore (Nb 2 o 5 Content is 2.37%, TiO 2 content 4.13%, Fe content 16.75%, rare earth oxide REO content 3.32%, CaO content 14.03%, SiO 2 Content 12.75%, MgO content 10.05%, Al 2 o 3 Content 1.87%, niobium mainly exists in niobite, niobium-iron rutile, calcite form), reducing agent (the present embodiment selects coke, and its C content 84%) carries out mixing batching by the mass ratio of 100:4;

[0042] (2) Put the ingredients obtained in step (1) into the electric furnace for smelting, smelting and producing slag and flue gas; control the smelting temperature at 1500°C, and the smelting time for 30 minutes; adjust the furnace by controlling the composition of the ingredients in step (1). Oxygen potential to a suitable range, this step smelting does not pro...

Embodiment 2

[0048] A method for comprehensively recovering niobium, rare earth and titanium from polymetallic ores containing iron, niobium and rare earth, comprising the steps of:

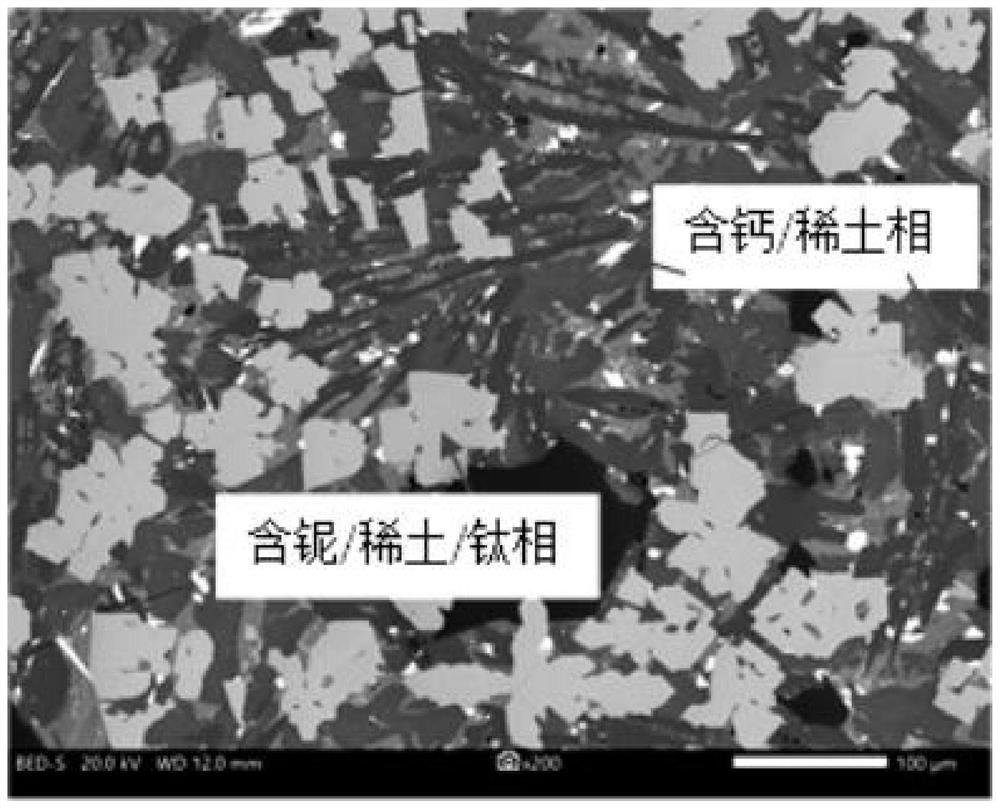

[0049] (1) Iron, niobium, rare earth polymetallic ore (Nb 2 o 5 Content is 3.52%, TiO 2 content 4.29%, Fe content 14.03%, rare earth oxide REO content 1.50%, CaO content 14.03%, SiO 2 Content 12.75%, MgO content 10.05%, Al 2 o 3 content of 1.87%, niobium mainly exists in the form of niobite, niobium-iron rutile, and calcite), slagging agent (this embodiment selects limestone and dolomite with a mass ratio of 1:1), reducing agent (this embodiment selects mass ratio Ratio 1:0.5 anthracite and granulated coal, the average C content is 83%) are mixed and proportioned according to the mass ratio of 100:5:10;

[0050] (2) put the ingredients obtained in step (1) into the converter for smelting, and smelt to produce iron-containing alloys, slag and flue gas; control the smelting temperature to 1450 ° C, and sme...

Embodiment 3

[0056] A method for comprehensively recovering niobium, rare earth and titanium from polymetallic ores containing iron, niobium and rare earth, comprising the steps of:

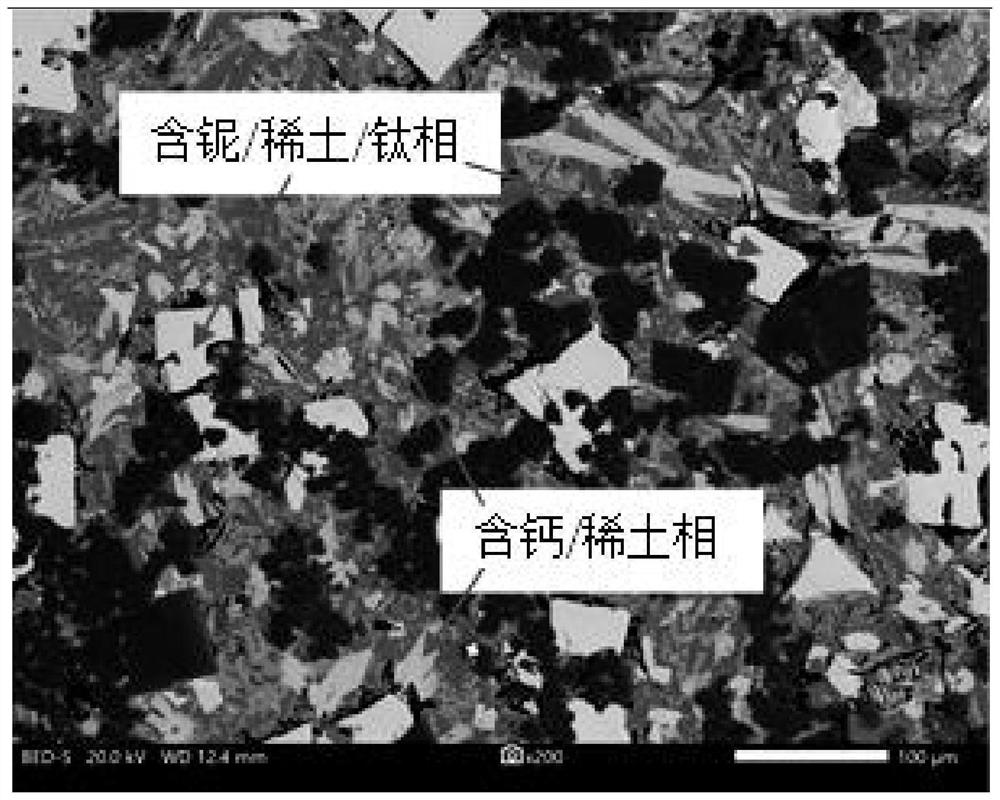

[0057] (1) Iron, niobium, rare earth polymetallic ore (Nb 2 o 5 Content is 5.40%, TiO 2 content 4.29%, Fe content 35.09%, rare earth oxide REO content 4.11%, CaO content 3.91%, SiO 2 Content 20.05%, MgO content 1.17%, Al 2 o 3 Content 0.34%, niobium mainly exists in niobite, niobium-iron rutile, calcite form), slagging agent (this embodiment selects silica), reducing agent (this embodiment selects pulverized coal) according to the ratio of 100:10:18 Mix the ingredients according to the mass ratio;

[0058] (2) Put the ingredients obtained in step (1) into the blast furnace for smelting, and smelt to produce iron-containing alloys, slag and flue gas; control the smelting temperature to 1550° C., and the smelting time for 20 minutes; by controlling the ingredients in the step (1), and Monitor the recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com