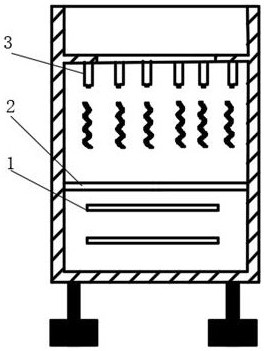

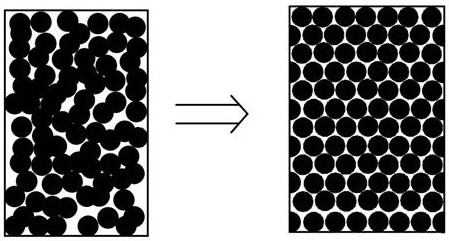

Highly ordered lithium battery block polymer electrolyte membrane and preparation method thereof

A block polymer, highly ordered technology, used in composite electrolytes, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of uneven distribution of electrolyte membrane impedance, influence, low electrical conductivity, etc. rate, the effect that is conducive to conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a. Mix the ferrous salt and the ferric salt according to the molar ratio of 1:1.8 to obtain the mixed iron salt, then add it into deionized water, and add an alkaline solution containing a surfactant to react, after separation, washing, Follow-up treatment such as drying obtains nano-ferric oxide particles; wherein, 32 parts by weight of mixed iron salt, 48 parts by weight of deionized water, 2 parts by weight of surfactant, and 18 parts by weight of alkaline solution; Ferrous iron, ferric salt is ferric chloride, and tensio-active agent is stearic acid, and alkali solution is the sodium hydroxide solution that mass concentration is 35%;

[0034] b. Mix styrene and ethylene glycol uniformly, configure it as a solution, add the nano-iron ferric oxide particles obtained in step (a) into the solution, perform ball milling to disperse evenly, and obtain a mixed slurry; wherein, 35 parts by weight of styrene , 53 parts by weight of ethylene glycol, 12 parts by weight of nano...

Embodiment 2

[0037]a. Mix the ferrous salt and the ferric salt according to the molar ratio of 1:1.75 to obtain the mixed iron salt, then add it into deionized water, and add an alkaline solution containing a surfactant to react, after separation, washing, Follow-up treatment such as drying obtains nano ferric oxide particles; wherein, 32 parts by weight of mixed iron salt, 50 parts by weight of deionized water, 1 part by weight of surfactant, and 17 parts by weight of alkaline solution; Iron, ferric salt is ferric nitrate, surfactant is sodium dodecylbenzene sulfonate, and alkali solution is the potassium hydroxide solution that mass concentration is 32%;

[0038] b. Mix styrene and ethylene glycol evenly, configure it as a solution, add the nano-iron ferric oxide particles obtained in step (a) into the solution, perform ball milling to disperse evenly, and obtain a mixed slurry; wherein, 33 parts by weight of styrene , 55 parts by weight of ethylene glycol, 12 parts by weight of nano fer...

Embodiment 3

[0041] a. Mix the ferrous salt and the ferric salt according to the molar ratio of 1:1.95 to obtain the mixed iron salt, then add deionized water, and add an alkaline solution containing a surfactant to react, separate, wash, Follow-up treatment such as drying obtains nano ferric oxide particles; wherein, 34 parts by weight of mixed iron salt, 46 parts by weight of deionized water, 2 parts by weight of surfactant, 18 parts by weight of alkali solution; Iron, ferric salt is ferric sulfate, surfactant is sodium dioctyl succinate sulfonate, and alkali solution is the sodium hydroxide solution that mass concentration is 38%;

[0042] b. Mix styrene and ethylene glycol uniformly, configure it as a solution, add the nano-iron ferric oxide particles obtained in step (a) into the solution, and perform ball milling to disperse evenly to obtain a mixed slurry; wherein, 37 parts by weight of styrene , 49 parts by weight of ethylene glycol, 14 parts by weight of nano ferric oxide particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com