Hydrogenolysis catalyst, preparation method and application of hydrogenolysis catalyst in preparation of isopropyl benzene by hydrogenolysis of alpha, alpha-dimethyl benzyl alcohol

A technology of dimethyl benzyl alcohol and catalyst, which is applied in the field of catalysis, can solve the problems of decreased activity and loss of active components, and achieve the effects of increasing hardness, improving dispersion, and saving preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

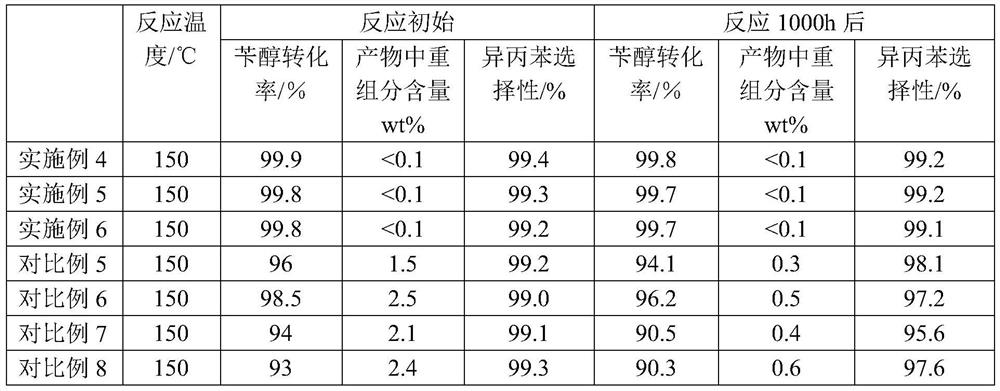

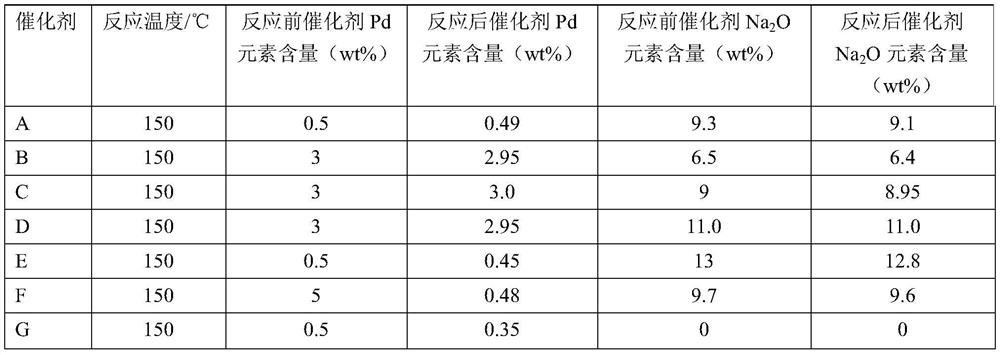

Examples

Embodiment 1

[0056] A kind of preparation method of hydrogenolysis catalyst, the steps are:

[0057] 1) First weigh 70.6g of pseudo-boehmite, 12.5g of coconut shell charcoal and 3.0g of safflower powder and carry out dry mixing in a mixer, the motor speed is 15r / min, the dry mixing time is 30min, and then 26g Ionized water, 69.3g sodium silicate aqueous solution (solid content 40wt%, modulus is about 2.7), 0.87g yttrium chloride and 2.5g palladium chloride ammonia solution (palladium element mass concentration is 20wt%) mix, and this solution Add it into a kneader for kneading, the kneading time is 20min, and the motor speed is 15r / min, to obtain a wet dough.

[0058] 3) Put the wet dough in step 2) into a twin-screw extruder for extrusion molding. The extrusion conditions are room temperature, the extrusion pressure is 70N, the extrusion rate is 20rpm, and the extrusion abrasive is cylindrical, with a diameter of 2mm ;

[0059] 4) The strip-shaped wet base body obtained in step 3) was q...

Embodiment 2

[0062] A kind of preparation method of hydrogenolysis catalyst, the steps are:

[0063] 1) First weigh 70.6g of SB powder, 10.0g of coconut shell charcoal and 3g of turnip powder in a mixer for dry mixing, the motor speed is 15r / min, and the dry mixing time is 30min, then 20g of deionized water, 69.4 G sodium silicate aqueous solution (solid content 40wt%, modulus is about 2.7), 1.69g yttrium nitrate and 15g palladium chloride ammonia solution (palladium element mass concentration is 20wt%) are mixed, and this solution is added in the kneader and kneaded , the kneading time is 20min, the motor speed is 15r / min, and the wet dough is obtained.

[0064] 3) Put the wet dough in step 2) into a twin-screw extruder for extrusion molding. The extrusion conditions are room temperature, extrusion pressure 80N, extrusion rate 20rpm, extrusion abrasive is cylindrical, diameter 2mm ;

[0065] 4) The strip-shaped wet base body obtained in step 3) was quickly dried in a drying oven at 80°C...

Embodiment 3

[0068] A kind of preparation method of hydrogenolysis catalyst, the steps are:

[0069] 1) First weigh 35.3g of pseudo-boehmite, 27.0g of coconut shell charcoal and 3g of safflower powder and dry mix them in a mixer, the motor speed is 15r / min, the dry mixing time is 30min, and then 22g of deionized Water, 5.2g yttrium chloride and 97.1g sodium silicate aqueous solution (solid content 40wt%, modulus is about 2.7) are mixed with the ammonia solution of 15g palladium chloride (the mass concentration of palladium element is 20wt%), this solution is added and kneaded Carry out kneading in the machine, the kneading time is 20min, the motor speed is 15r / min, and the wet dough is obtained.

[0070] 3) Put the wet dough in step 2) into a twin-screw extruder for extrusion molding. The extrusion conditions are room temperature, the extrusion pressure is 70N, the extrusion rate is 20rpm, and the extrusion abrasive is cylindrical, with a diameter of 2mm ;

[0071] 4) The strip-shaped we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com