Method for producing n-butene from isobutene

A technology for isobutene and n-butene, which is applied in chemical instruments and methods, isomerization hydrocarbon production, and hydrocarbon purification/separation, etc., which can solve the problem that the concentration of isobutene cannot be met, the yield of n-butene is low, and it cannot be alkylated. Use of chemical raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

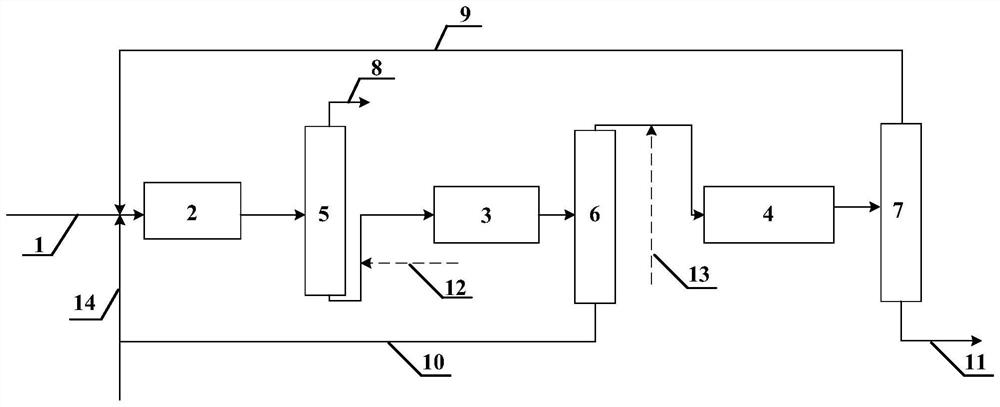

Image

Examples

Embodiment approach

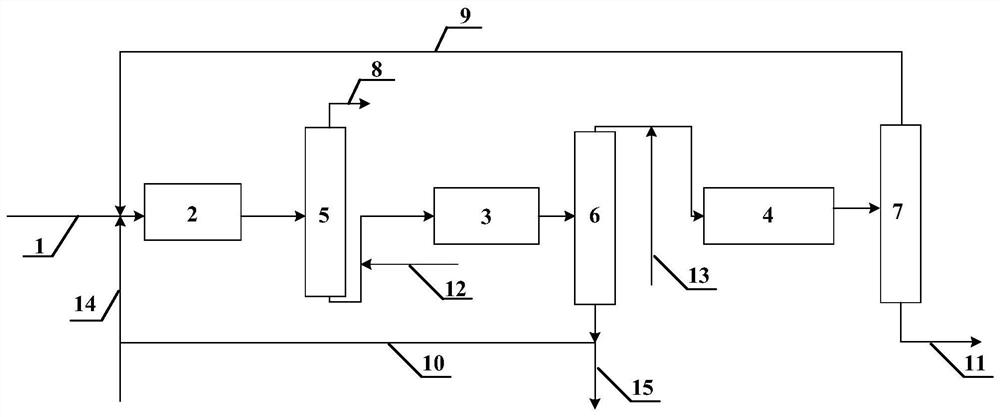

[0032] The inventive method also can have another kind of implementation method: (2) step described methyl tertiary butyl ether is the mixture that adds methyl tertiary butyl ether and (1) step gained methyl tertiary butyl ether, (3) The isobutene described in the step is a mixture of isobutene and (2) step gained isobutene. In this case, the raw materials of the inventive method are C4 hydrocarbons, methyl tert-butyl ether and isobutene containing isobutene, and the C4 hydrocarbons containing isobutene are The mass ratio of the hydrocarbon, the added methyl tert-butyl ether, and the added isobutylene is 1:0.1-10:0.1-10.

[0033] The added methyl tert-butyl ether in the present invention comes from the etherification unit of the isobutane-propylene co-oxidation unit or other etherification units, and the added isobutene comes from high-purity isobutene obtained after dehydration and refining of tert-butanol.

[0034] The catalyst used for the isobutene normalization reaction i...

example 1

[0058] The normalization catalyst described in the present invention is prepared.

[0059] (1) Preparation of preform

[0060] Take SiO 2 / Al 2 o 3 Mole ratio is 90.0g of HZSM-35 molecular sieve and 5.0g white carbon black, 20.0g alkaline silica sol (SiO in silica sol 2 Content is 30% by mass, Na 2 O content is 0.4 mass %), the NaOH of 0.5g and 30.0g deionized water are mixed uniformly, and its molar composition is 0.041Na 2 O: 8.0ZSM-35 molecular sieve: SiO 2 : 15.1H 2 O, the number of moles of the ZSM-35 molecular sieve is calculated by SiO contained therein 2 The number of moles (the same below). The mixture was kneaded evenly, extruded into strands, and dried at 120°C for 10 hours to obtain a preform. The specific surface area of the ZSM-35 molecular sieve measured by the BET method is 298m2 / g, the micropore specific surface area is 280m 2 / g, the pore volume is 0.202ml / g, and the micropore volume is 0.130ml / g.

[0061] (2) Preparation of composite carrier

...

example 2

[0066] Catalyst is prepared by the method of example 1, difference is the SiO of ZSM-35 molecular sieve used 2 / Al 2 o 3 Molar ratio is 52, and (3) step is that the nickel chloride of 0.5gNi / ml replaces palladium chloride with 20ml concentration, makes catalyst B, wherein the Ni content calculated on the basis of composite carrier is 0.05 mass %, Na 2 The O content is 0.02% by mass, and the composite carrier is composed of 89.1% by mass of ZSM-35 molecular sieve and 10.9% by mass of all-silicon ZSM-35 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com