A kind of 3D graphene carbon-nickel hydrogen battery and preparation method thereof

A nickel-metal hydride battery and carbon alkene technology, which is applied in the manufacture of nickel storage batteries, alkaline storage batteries, battery electrodes, etc., can solve the problem that the key performance of battery specific capacity and specific energy has not been significantly improved, and graphene has high conductivity and high The specific surface properties have not been fully utilized, and the high conductivity of graphene cannot be fully utilized, so as to achieve stable and controllable product performance, low manufacturing cost, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment provides a method for preparing a 3D graphene carbon-nickel-metal hydride battery, the details are as follows:

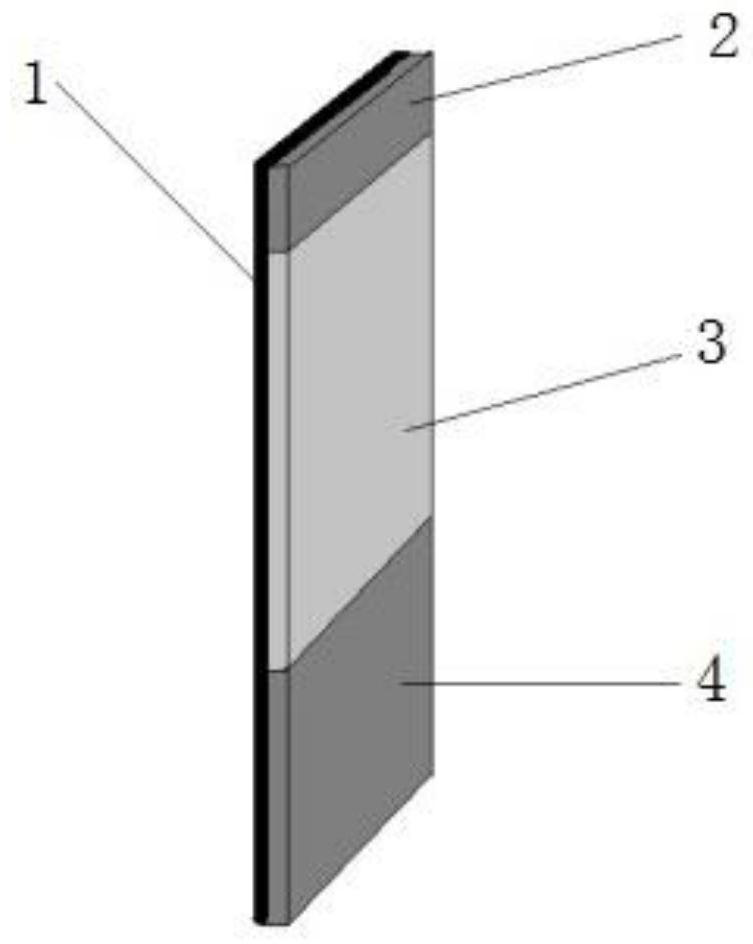

[0056] (1) Take a piece of flexible expanded graphite paper strip of 1cm*3cm and thickness of 0.05mm, wash and dry, mix 96.85% of acetylene black, 1.55% of sodium carboxymethyl cellulose, and 1.60% of styrene-butadiene rubber, fully stir evenly, adjust into a paste-like conductive paste; spread the paste-like paste evenly on one side of the graphite paper strip, such as figure 2 As shown in the figure, a layer of carbon-containing conductive adhesive 1 is formed, and the coating thickness is 0.08 mm, and then the coated expanded graphite-carbon-containing conductive adhesive sheet is vacuum-dried at room temperature for 5 hours to obtain the expanded graphite-carbon-containing conductive adhesive. Composite flakes.

[0057] (2) The graphite surface 1cm*1cm at one end of the expanded graphite-carbon-containing conductive adhesive compo...

Embodiment 2

[0061] The present embodiment provides a method for preparing a 3D graphene carbon-nickel-metal hydride battery, the details are as follows:

[0062] (1) Take a piece of flexible expanded graphite paper strip of 1cm*3cm and thickness of 0.05mm, wash and dry, mix 96.85% of acetylene black, 1.55% of sodium carboxymethyl cellulose, and 1.60% of styrene-butadiene rubber, fully stir evenly, adjust into a paste-like conductive paste; spread the paste-like paste evenly on one side of the graphite paper strip, such as figure 2 As shown in the figure, a layer of carbon-containing conductive adhesive 1 is formed, and the coating thickness is 0.08 mm, and then the coated expanded graphite-conductive adhesive sheet is vacuum-dried at room temperature for 5 hours to obtain an expanded graphite-carbon-containing conductive adhesive composite sheet .

[0063] (2) The graphite surface of one end of the expanded graphite-carbon-containing conductive adhesive composite sheet is 1cm*1cm as the...

Embodiment 3

[0067] The present embodiment provides a method for preparing a 3D graphene carbon-nickel-metal hydride battery, the details are as follows:

[0068] (1) Take a piece of flexible expanded graphite paper strip of 1cm*3cm and thickness of 0.05mm, wash and dry, mix 96.85% of acetylene black, 1.55% of sodium carboxymethyl cellulose, and 1.60% of styrene-butadiene rubber, fully stir evenly, adjust into a paste-like conductive paste; spread the paste-like paste evenly on one side of the graphite paper strip, such as figure 2 As shown in the figure, a layer of carbon-containing conductive adhesive 1 is formed, and the coating thickness is 0.08 mm, and then the coated expanded graphite-conductive adhesive sheet is vacuum-dried at room temperature for 5 hours to obtain an expanded graphite-carbon-containing conductive adhesive composite sheet. .

[0069](2) The graphite surface of one end of the expanded graphite-carbon-containing conductive adhesive composite sheet is 1cm*1cm in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com