Antibacterial wound dressing based on visible light up-conversion material and preparation method thereof

A technology for converting materials and wound dressings, which can be used in pharmaceutical formulations, medical science, absorbent pads, etc., and can solve problems such as bacterial resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

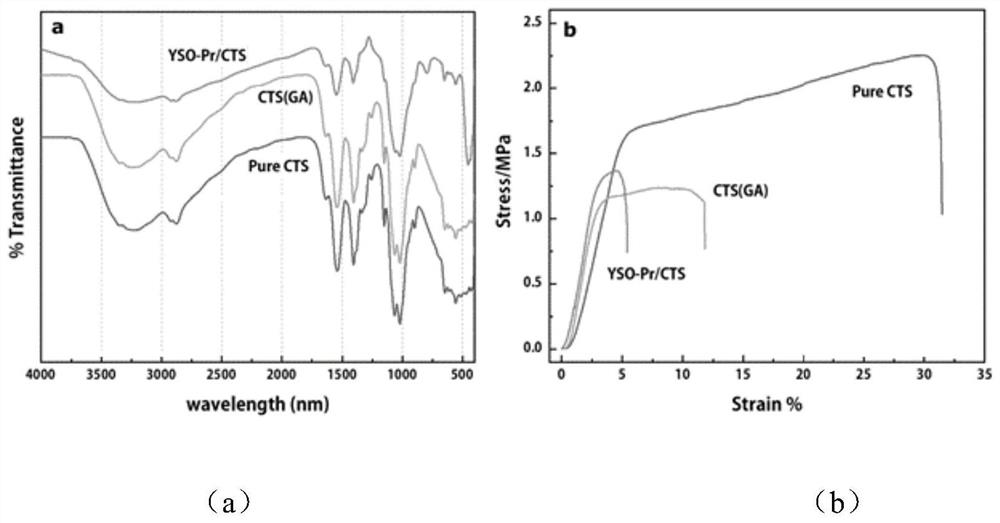

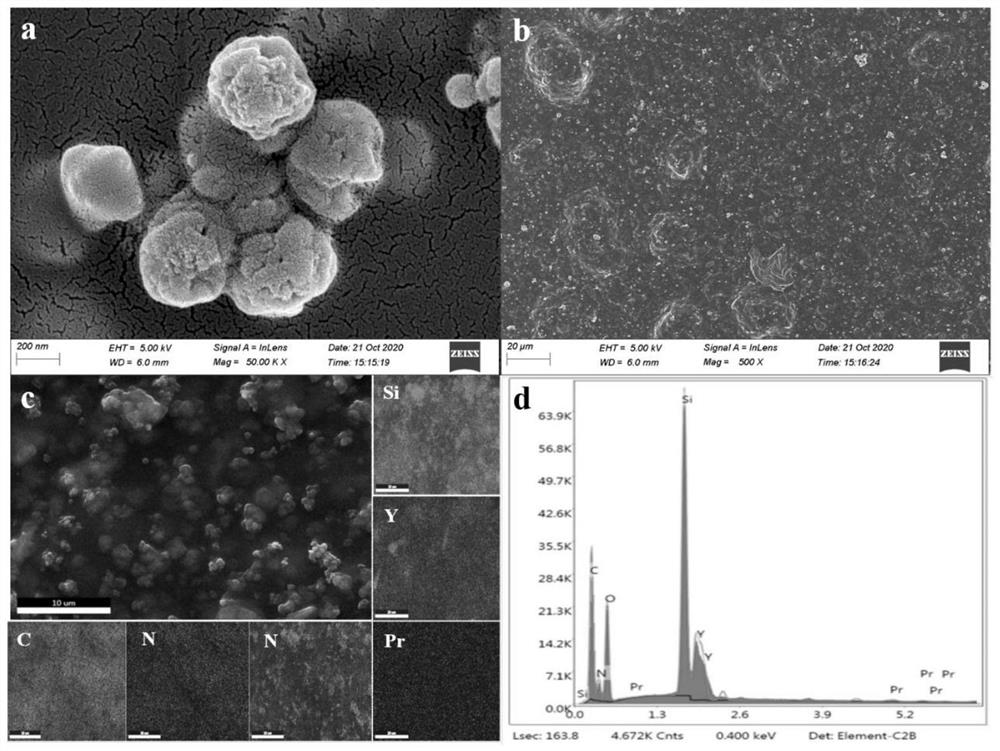

[0033] The invention discloses an up-converted visible light bacteriostatic wound auxiliary material and a preparation method thereof. The specific preparation process includes:

[0034] 1) Add 2.6g of cetyltrimethylammonium bromide to 120ml of water, 600w ultrasonic treatment for 10 minutes to accelerate dissolution to obtain cetyltrimethylammonium bromide solution A, add 50ml of ethanol to solution A, 12ml of ammonia water, magnetically stirred until uniform, to obtain solution B. Add 4ml tetraethyl orthosilicate to solution B dropwise, making solution B gradually become turbid until a large amount of white precipitate appears, and keep stirring for 30 minutes to make it fully react. The white precipitate was repeatedly washed with deionized water and centrifuged several times, and then placed in an electric blast dryer at 60-80°C for 6-8 hours to completely dry it to obtain white solid C. After the white solid C was ground, it was kept in a muffle furnace at 550° C. for ca...

Embodiment 1

[0042] 1) Add 2.6g of cetyltrimethylammonium bromide to 120ml of water, 600w ultrasonic treatment for 10 minutes to accelerate the dissolution, to obtain cetyltrimethylammonium bromide solution A, add 50ml of ethanol to solution A , 12ml of ammonia water, magnetically stirred until uniform, and solution B was obtained. Add 4ml tetraethyl orthosilicate to solution B dropwise, making solution B gradually become turbid until a large amount of white precipitate appears, and keep stirring for 30 minutes to make it fully react. The white precipitate was repeatedly washed with deionized water and centrifuged several times, and then placed in an electric blast dryer at 60°C for 6 hours to completely dry it to obtain a white solid C. After the white solid C was ground, it was kept in a muffle furnace at 550° C. for calcination for 5 h to obtain white mesoporous silica powder.

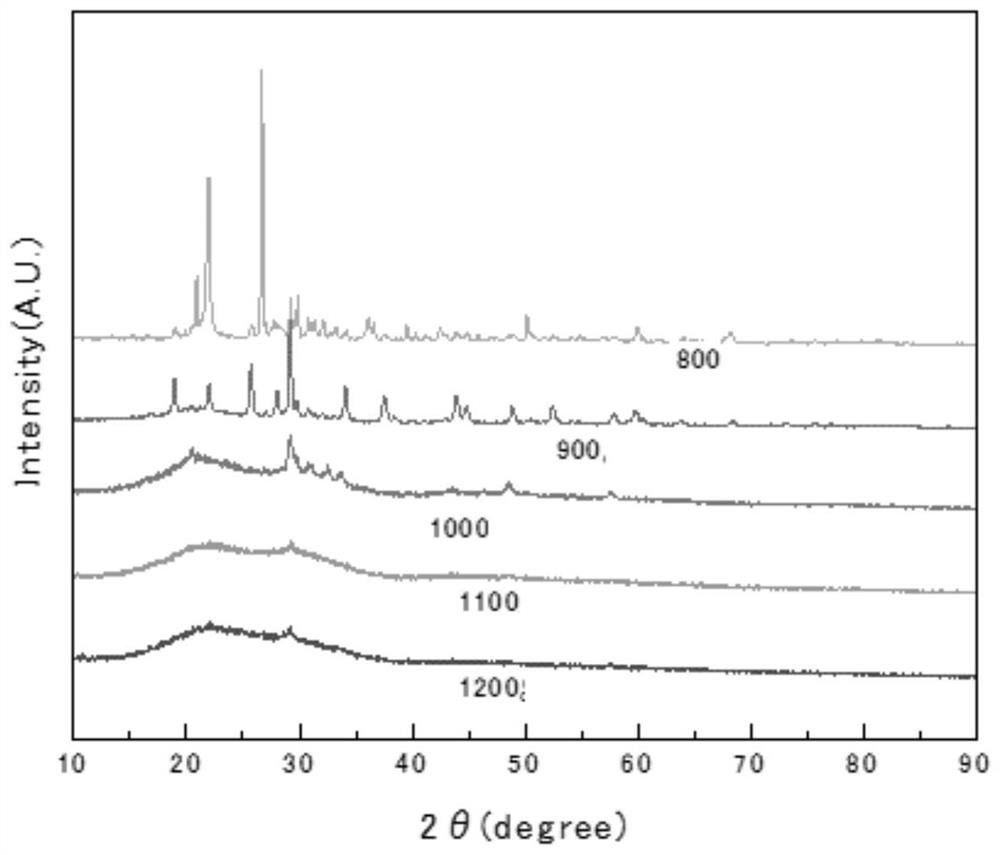

[0043] 2) Mix 2.025g of yttrium oxide with 13.5ml of nitric acid solution (V fuming nitric acid: V deionized...

Embodiment 2

[0051] Calcination temperature in this embodiment The calcination temperature of the white solid in Step 2 is 800° C., and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com