Cement grinding aid for enhancing yield increase

The technology of cement grinding aid and reinforcing agent is applied in the field of cement processing, which can solve the problems of large amount of modified triethanolamine, toxicity of chlorinated hydrocarbons and high cost, so as to reduce the energy consumption of grinding, ensure the early strength and increase the output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

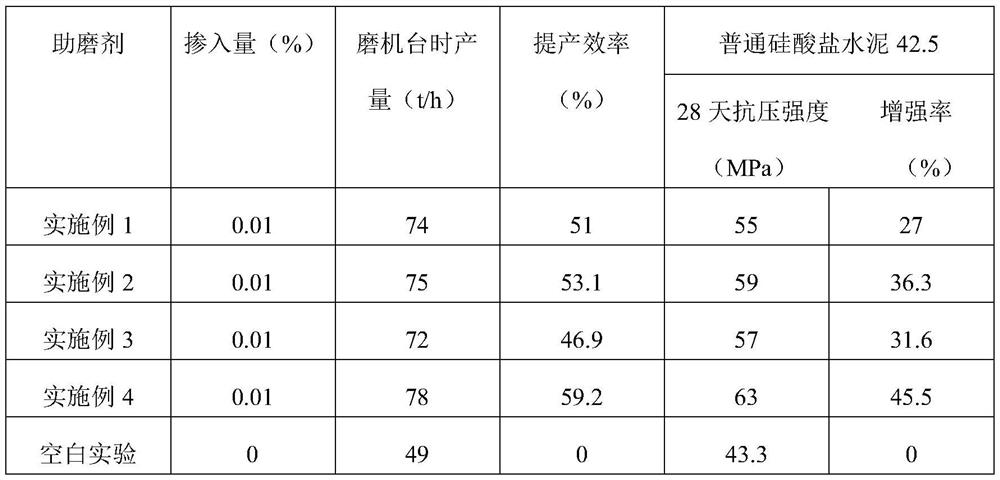

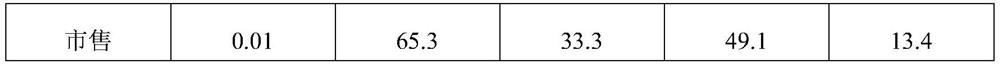

Examples

Embodiment 1

[0027] A cement grinding aid for increasing production, which is prepared from the following components in weight percentage: 20% of alcohol amine organic small molecule modified graphene mixed solution, 18% of inorganic early strengthening agent, 5% of inorganic coagulation accelerator, Sodium dodecyl sulfonate 5%, beet molasses 9%, mixed glycol 8%, the rest is deionized water;

[0028] The alcohol amine organic small molecule modified graphene mixed solution is prepared from the alcohol amine mixture, graphene, and deionized water. The alcohol amine organic small molecule is triethanolamine and diethanol monoiso A mixture of propanolamine and triisopropanolamine, the mass ratio of alcoholamine mixture, graphene, and deionized water is 1:0.3:1.5:

[0029] The inorganic early reinforcing agent is a mixture of talcum powder and glass fiber with a mass ratio of 3:1;

[0030] The inorganic coagulant is borax;

[0031] The mixed glycol is a mixture of ethylene glycol, diethylene...

Embodiment 2

[0038] A cement grinding aid for increasing production, which is prepared from the following components in weight percent: 15% of alcohol amine organic small molecule modified graphene mixed solution, 20% of inorganic early strengthening agent, 7% of inorganic coagulation accelerator, Sodium dodecyl sulfonate 3%, sugar cane molasses 10%, mixed glycol 9%, the rest is deionized water;

[0039]The alcohol amine organic small molecule modified graphene mixed solution is prepared from the alcohol amine mixture, graphene, and deionized water. The alcohol amine organic small molecule is triethanolamine and diethanol monoiso A mixture of propanolamine and triisopropanolamine, the mass ratio of alcoholamine mixture, graphene, and deionized water is 1:0.1:1.5:

[0040] The inorganic early reinforcing agent is a mixture of talcum powder and glass fiber with a mass ratio of 3:1;

[0041] The inorganic coagulant is borax;

[0042] The mixed glycol is a mixture of ethylene glycol, diethyl...

Embodiment 3

[0049] A cement grinding aid for increasing production, which is prepared from the following components in weight percentage: 17% of alcohol amine organic small molecule modified graphene mixed solution, 15% of inorganic early strengthening agent, 8% of inorganic coagulation accelerator, 4% sodium dodecyl sulfonate, 8% glucose molasses, 10% mixed glycol, and the rest is deionized water;

[0050] The alcohol amine organic small molecule modified graphene mixed solution is prepared from the alcohol amine mixture, graphene, and deionized water. The alcohol amine organic small molecule is triethanolamine and diethanol monoiso A mixture of propanolamine and triisopropanolamine, the mass ratio of alcoholamine mixture, graphene, and deionized water is 1:0.2:1.5:

[0051] The inorganic early reinforcing agent is a mixture of talcum powder and glass fiber with a mass ratio of 3:1;

[0052] The inorganic coagulant is borax;

[0053] The mixed glycol is a mixture of ethylene glycol, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com