High-strength alkali-free liquid accelerator and preparation method thereof

An accelerator and high-strength technology, which is applied in the field of alkali-free liquid accelerator and its preparation, can solve the problems of strong ammonia odor, large loss of cement concrete strength, and damage to the health of construction workers, so as to improve the early and later strength , the late strength retention rate is large, and the effect of enhancing the steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

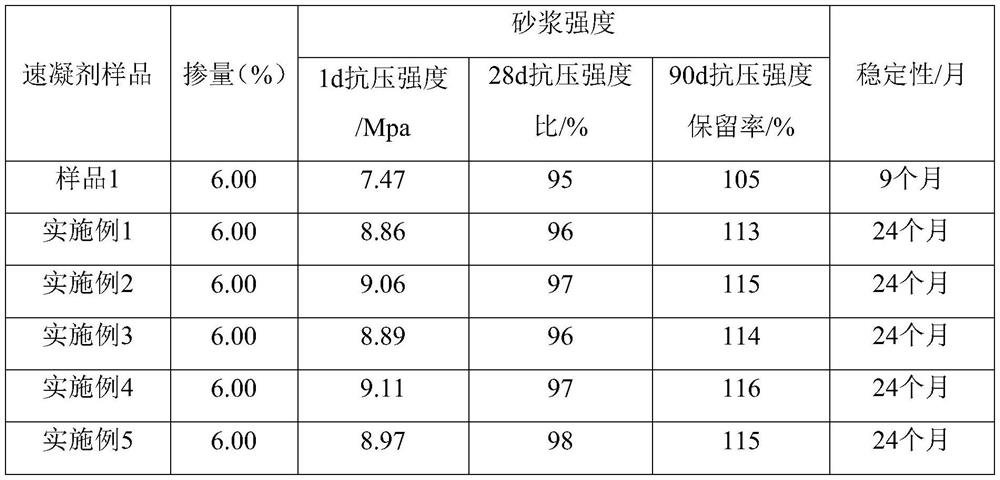

Embodiment 1

[0047] The massfraction of the high-strength type non-alkali liquid quick-setting agent raw material of the present embodiment is as follows:

[0048] Aluminum sulfate: 15.9%;

[0049] Fluorosilicic acid: 7.5%;

[0050] Aluminum hydroxide: 6.2%;

[0051] Alcohol amine compounds (triethanolamine): 3.4%;

[0052] Organic polymer coagulation accelerator component (polyisobutylene): 12.4%;

[0053] Dispersant: (polyacrylamide) 0.5%;

[0054] water: surplus;

[0055] The sum of the mass percentages of the above components is 100%.

[0056] The preparation method of the high-strength alkali-free liquid quick-setting agent of the present embodiment:

[0057] (1) Add 83.00g of fluosilicic acid and 615.80g of water into the reactor, turn on the stirring device and keep stirring in step (1) at a speed of 3000 rpm, and control the temperature in the reactor to 65°C. 78.00g of aluminum hydroxide was added in two times, and the heat preservation reaction was carried out for 2 hours ...

Embodiment 2

[0060] The massfraction of the high-strength type non-alkali liquid quick-setting agent raw material of the present embodiment is as follows:

[0061] Aluminum sulfate: 18.2%;

[0062] Fluorosilicic acid: 6.7%;

[0063]Aluminum hydroxide: 6.6%;

[0064] Alcohol amine compounds (triisopropanolamine): 4.5%;

[0065] Organic polymer coagulation accelerator component (polyvinyl alcohol): 16.8%;

[0066] Dispersant: (polyethylene glycol) 1.1%;

[0067] water: surplus;

[0068] The sum of the mass percentages of the above components is 100%.

[0069] The preparation method of the high-strength alkali-free liquid quick-setting agent of the present embodiment:

[0070] (1) Add 80.00g of fluosilicic acid and 582.60g of water into the reaction kettle, turn on the stirring device and keep stirring in step (1) at a speed of 4000 rpm, and control the temperature in the reaction kettle to 60°C. 78.00g of aluminum hydroxide was added in two times, and the heat preservation reaction wa...

Embodiment 3

[0073] The massfraction of the high-strength type non-alkali liquid quick-setting agent raw material of the present embodiment is as follows:

[0074] Aluminum sulfate: 20.2%;

[0075] Hydrofluoric acid: 7.7%;

[0076] Aluminum hydroxide: 6.9%;

[0077] Alcohol amine compounds (diethanolamine): 4.4%;

[0078] Organic polymer coagulation accelerator component (polyvinyl alcohol): 15.1%;

[0079] Dispersant: (hydrated magnesium silicate) 1.9%;

[0080] water: surplus;

[0081] The sum of the mass percentages of the above components is 100%.

[0082] The preparation method of the high-strength alkali-free liquid quick-setting agent of the present embodiment:

[0083] (1) Add 92.00g of hydrofluoric acid and 548.6g of bottom water into the reactor, turn on the stirring device and keep stirring in step (1), the rotating speed is 5000 rpm, and the temperature in the reactor is controlled to be 60°C. Add 83.00g of aluminum hydroxide in two times, and keep it warm for 2.5 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com