Preparation method of conductive metal organic framework packaged copper azide/cuprous azide

An organic framework and conductive metal technology, applied in the direction of azide acid/azide/halogen azide, metal azide composition, copper organic compound, etc., can solve the problem of low copper content in deposition and collapse of porous carbon skeleton , dangerous azide gas and other issues, to achieve the safe and reliable preparation process, avoid the accumulation of electrostatic charge, and improve the effect of electrostatic safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation references of Cu(TCNQ)【Liu H, Liu Z, Qian X, et al.Field emission and electrical switching properties of large-area CuTCNQ nanotube arrays[J].Crystal Growth&Design,2009,10(1):237-243 .]: Specifically, Cu(TCNQ) was prepared on a copper substrate by an impregnation method.

[0027] References for the preparation of Cu-CAT [Hmadeh M, Lu Z, Liu Z, et al. New porous crystals of extended metal-catecholates [J]. Chemistry of Materials, 2012, 24(18): 3511-3513.]: specifically Cu-CAT was obtained by solvothermal method.

Embodiment 1

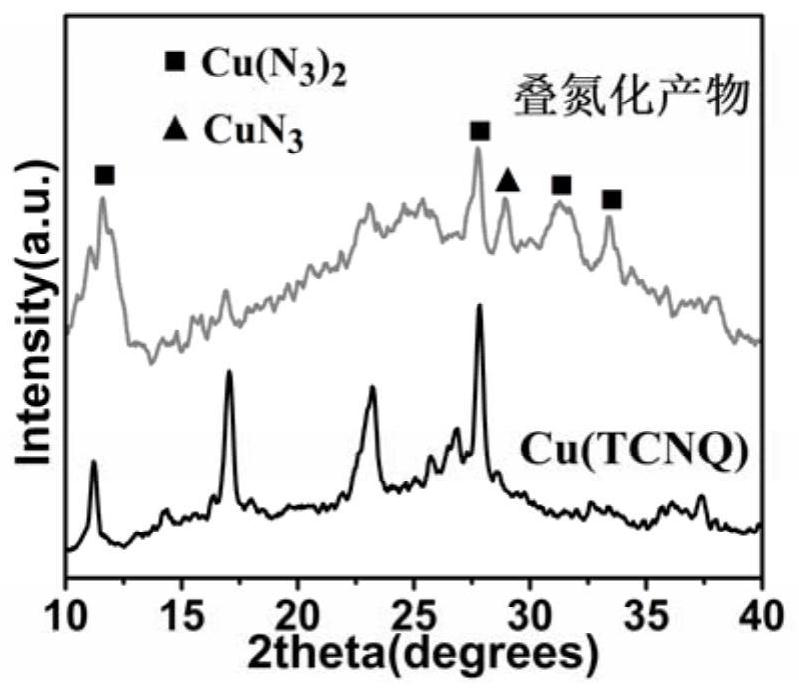

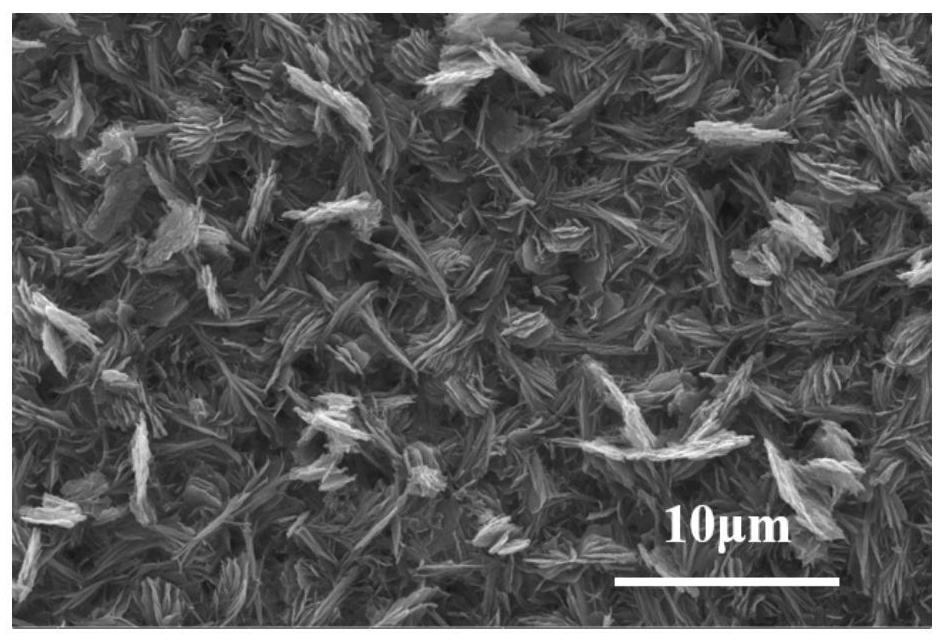

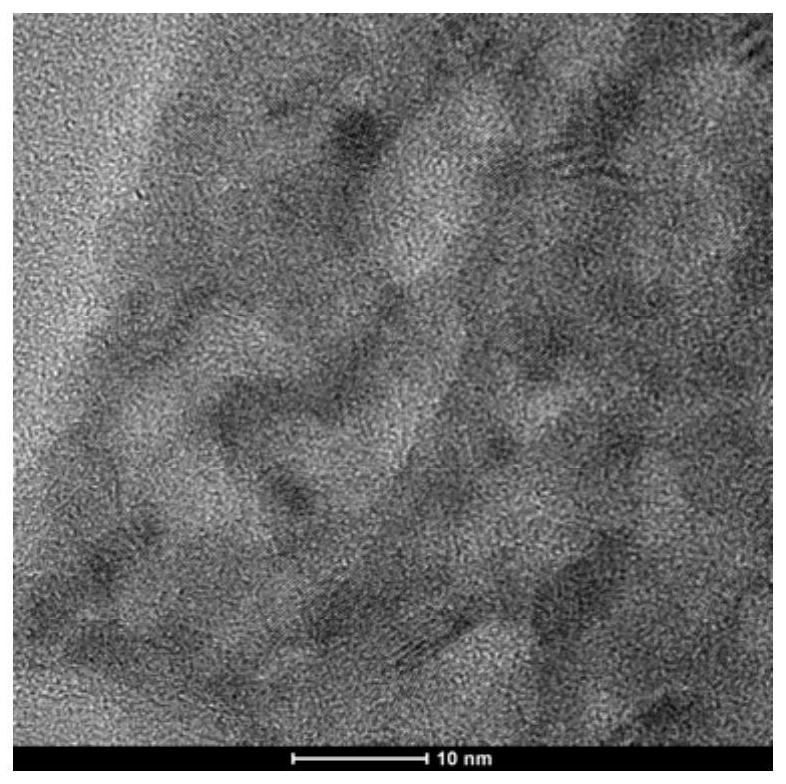

[0029] With Cu(TCNQ) film as the anode, 0.01mol / L sodium azide aqueous solution as the electrolyte, the current density is 0.1mA / cm 2 , Cu(TCNQ) completes the azidation reaction at the anode, and the reaction time is 240 minutes. After the reaction is completed, it is dried to obtain Cu(TCNQ) packaged copper azide / cuprous azide material.

Embodiment 2

[0031] With Cu(TCNQ) film as anode, 0.02mol / L sodium azide aqueous solution as electrolyte, current density is 0.1mA / cm 2 , Cu(TCNQ) completes the azidation reaction at the anode, and the reaction time is 240 minutes. After the reaction is completed, it is dried to obtain Cu(TCNQ) packaged copper azide / cuprous azide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com