A low-profile electrolytic copper foil for high-density interconnect circuit boards

An electrolytic copper foil, low profile technology, applied in the field of copper foil, can solve the problems of inability to meet the requirements of high-density interconnected circuit boards, adverse effects on circuit quality reliability, inability to meet fine line width and line spacing, etc., and achieve significant market competitiveness. , Excellent normal temperature tensile strength, wide applicability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

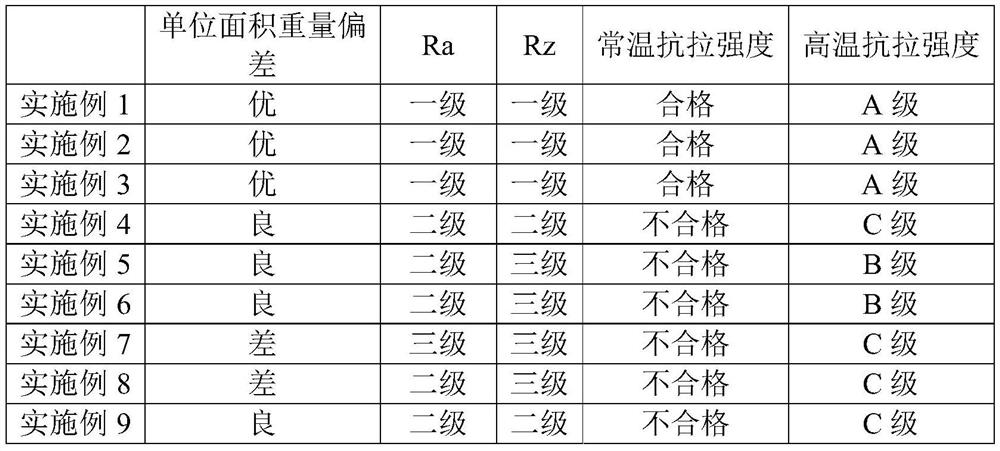

Examples

preparation example Construction

[0047] In one embodiment, the preparation method of the copper foil layer includes the following steps:

[0048] (1) Configure the electrolyte: Mix the copper salt, inorganic acid, chloride salt and leveling agent in the electrolyte evenly at 40-60°C and place it in the electrolytic cell;

[0049] (2) Electrochemical reaction: direct current, the current density is 40-80A / dm 2 Under the conditions, the copper foil is precipitated at the cathode and peeled off, that is, it is obtained.

[0050] In a preferred embodiment, the preparation method of the copper foil layer includes the following steps:

[0051] (1) Configure the electrolyte: mix the copper salt, inorganic acid, chloride salt and leveling agent in the electrolyte evenly at 50°C and place it in the electrolytic cell;

[0052] (2) Electrochemical reaction: direct current, at a current density of 70A / dm 2 Under the conditions, the copper foil is precipitated at the cathode and peeled off, that is, it is obtained.

...

Embodiment 1

[0102] Embodiment 1 of the present invention provides a low-profile electrolytic copper foil for a high-density interconnected circuit board, which sequentially includes a copper foil layer, a roughening treatment layer, a protective barrier layer, a passivation layer, and a silane coupling agent layer.

[0103] The copper foil layer is obtained by electrolysis in an electrolyte solution containing copper ions; the electrolyte solution is 250g / L copper salt, 70g / L inorganic acid, 10mg / L chloride salt, and 1.5mg / L leveling agent.

[0104] The copper salt is copper sulfate pentahydrate; the inorganic acid is sulfuric acid; the chloride salt is hydrochloric acid; the leveling agent is nonionic cellulose ether and leveling agent-1; the leveling agent-1 Contains amino and carboxyl groups, weight average molecular weight is 50000-60000, CAS: 9000-70-8, purchased from Rock Chemical; the non-ionic cellulose ether contains methoxy and hydroxyethyl, and the methoxy content is 22- 30wt%,...

Embodiment 2

[0124] Embodiment 2 of the present invention provides a low-profile electrolytic copper foil for a high-density interconnected circuit board, which sequentially includes a copper foil layer, a roughening treatment layer, a protective barrier layer, a passivation layer, and a silane coupling agent layer.

[0125] The copper foil layer is obtained by electrolysis in an electrolyte solution containing copper ions; the electrolyte solution is 350g / L copper salt, 150g / L inorganic acid, 80mg / L chloride salt, and 45mg / L leveling agent.

[0126] The copper salt is copper sulfate pentahydrate; the inorganic acid is sulfuric acid; the chloride salt is hydrochloric acid; the leveling agent is nonionic cellulose ether and leveling agent-1; the leveling agent-1 Contains amino and carboxyl groups, weight average molecular weight is 50000-60000, CAS: 9000-70-8, purchased from Rock Chemical; the non-ionic cellulose ether contains methoxy and hydroxyethyl, and the methoxy content is 22- 30wt%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com