Method for separating and purifying ultra-high molecular weight poly-gamma-glutamic acid from high-viscosity fermentation liquor

An ultra-high molecular weight, separation and purification technology, which is applied in the field of separation and purification of ultra-high molecular weight poly-γ-glutamic acid, can solve the problems of lower PGA recovery rate, low processing efficiency, and increased production costs, and achieve easy removal of low molecular weight impurities, Product purity and recovery rate are high, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

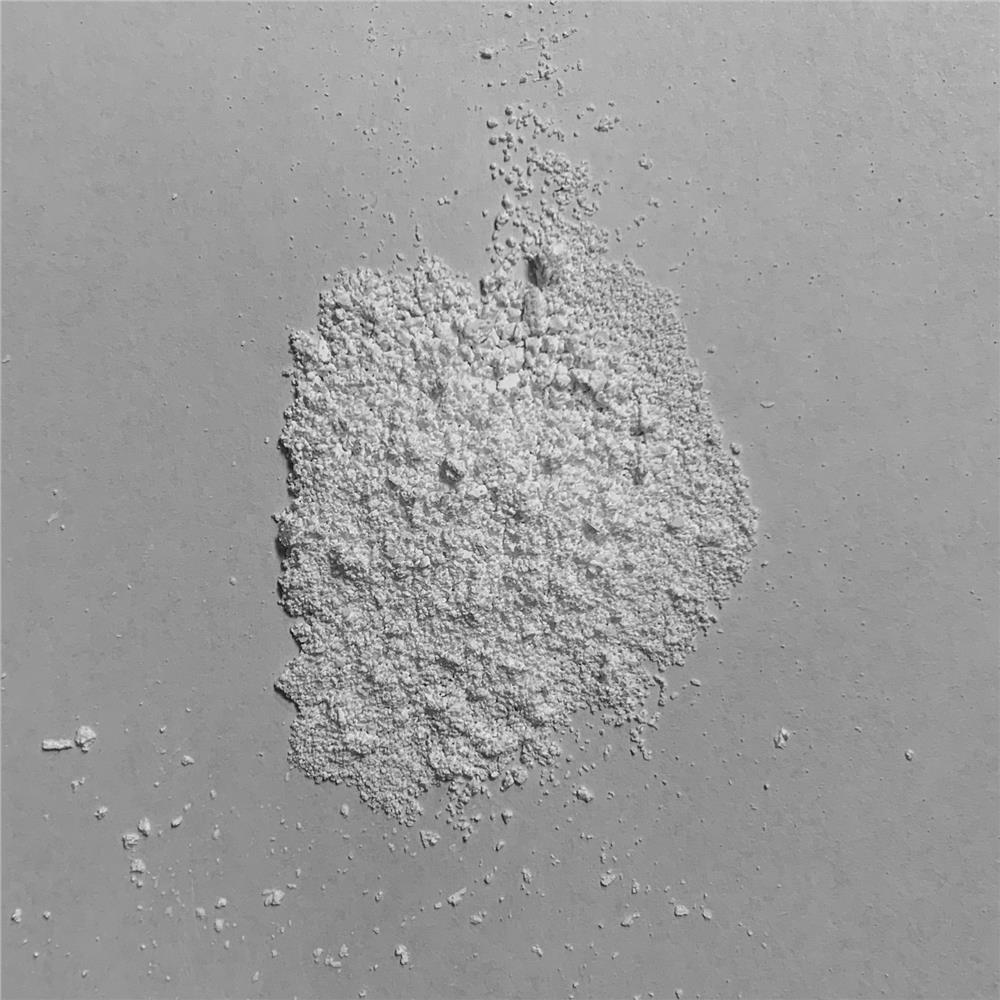

Image

Examples

Embodiment 1

[0037] A method for separating and purifying ultra-high molecular weight poly-γ-glutamic acid from high-viscosity fermentation broth, comprising the steps of:

[0038] (1) Dilute and acidify the fermentation broth

[0039] Use viscosity > 3000mpa s, molecular weight of poly-γ-glutamic acid contained in the fermentation broth > 2×10 6 The high-viscosity fermentation broth of poly-γ-glutamic acid was diluted to 2 times the original volume with distilled water in the fermenter, and then the pH was adjusted to 3 with 3 M HCl, at 37°C and 150r / min. Acidify for 30 minutes;

[0040] (2) Plate and frame filter

[0041] Add commercially available vermiculite powder filter aid to the diluted and acidified fermentation broth at a mass percentage of 1%, filter through a 400-mesh filter cloth, and filter with a plate and frame to remove bacteria and pigments at a pressure of 0.2 MPa;

[0042] (3) Cyclic ultrafiltration

[0043] The molecular weight cut-off is 3×10 5 The ultrafiltratio...

Embodiment 2

[0047] A method for separating and purifying ultra-high molecular weight poly-γ-glutamic acid from high-viscosity fermentation broth, comprising the steps of:

[0048] (1) Dilute and acidify the fermentation broth

[0049] Bacillus subtilis ( Bacillus subtilis ) GXA-28 (preservation number CCTCC NO: M2012347, depository unit: China Type Culture Collection Center) is a production strain, a high-viscosity fermentation broth containing ultra-high molecular weight poly-γ-glutamic acid obtained through liquid fermentation in a fermenter, The viscosity of the fermentation broth is >3000mpa·s, and the molecular weight of poly-γ-glutamic acid contained in the fermentation broth is >3×10 6 ; Dilute the fermentation broth to 5 times the original volume with distilled water in the fermenter, then adjust the pH to 5 with 3M HCl, and acidify for 90 minutes at 45°C and 250r / min;

[0050] (2) Plate and frame filter

[0051] Add the commercially available vermiculite powder filter aid to t...

Embodiment 3

[0057] A method for separating and purifying ultra-high molecular weight poly-γ-glutamic acid from high-viscosity fermentation broth, comprising the steps of:

[0058] (1) Dilute and acidify the fermentation broth

[0059] Use viscosity > 3000mpa s, molecular weight of poly-γ-glutamic acid contained in the fermentation broth > 2×10 6 The high-viscosity fermentation broth of poly-γ-glutamic acid was diluted to 2.5 times the original volume with distilled water in the fermenter, and then adjusted to pH 4 with 3 M HCl, at 42°C and 200r / min. Acidify for 60min;

[0060] (2) Plate and frame filter

[0061] Add the commercially available vermiculite powder filter aid to the diluted and acidified fermentation broth at a mass percentage of 2%, filter through a 600-mesh filter cloth, and filter with plate and frame to remove bacteria and pigments at a pressure of 0.2 MPa;

[0062] (3) Cyclic ultrafiltration

[0063] The molecular weight cut-off is 4×10 5 The ultrafiltration membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com