A kind of negative electrode material of lithium ion battery and preparation method and application thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of volume change destroying its own structure, active material shedding, low conductivity, etc., and achieve a simple and highly reversible preparation method. The effect of improving the high coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the lithium ion battery negative electrode material described in the above technical solution, comprising the following steps:

[0038] Mix titanium powder, niobium powder, aluminum powder and carbon powder, pre-press and discharge plasma sintering in sequence to obtain niobium-doped Ti 3 AlC 2 ; The molar ratio of the titanium powder, aluminum powder and carbon powder is 3:1:2;

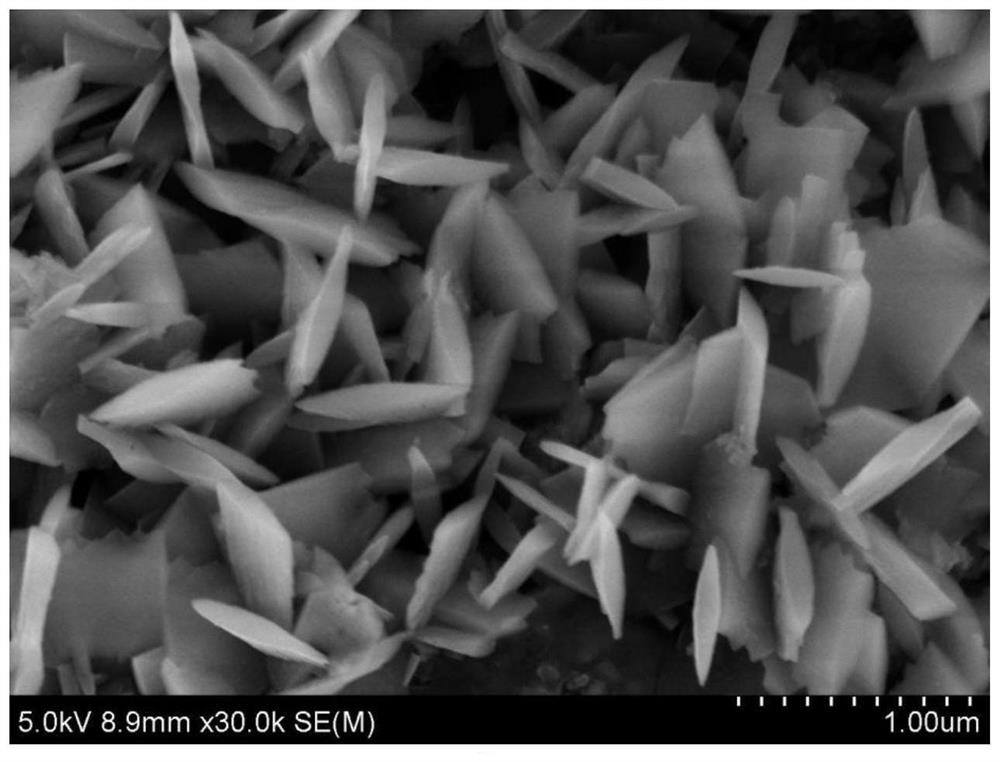

[0039] Doping the niobium with Ti 3 AlC 2 After pulverization, etching is carried out to obtain niobium-doped two-dimensional layered Ti 3 C 2 ;

[0040] The niobium doped two-dimensional layered Ti 3 C 2 calcining to obtain the lithium ion battery negative electrode material.

[0041] In the present invention, titanium powder, niobium powder, aluminum powder and carbon powder are mixed, followed by prepress molding and discharge plasma sintering to obtain niobium-doped Ti 3 AlC 2 ; The molar ratio of the titanium powder, al...

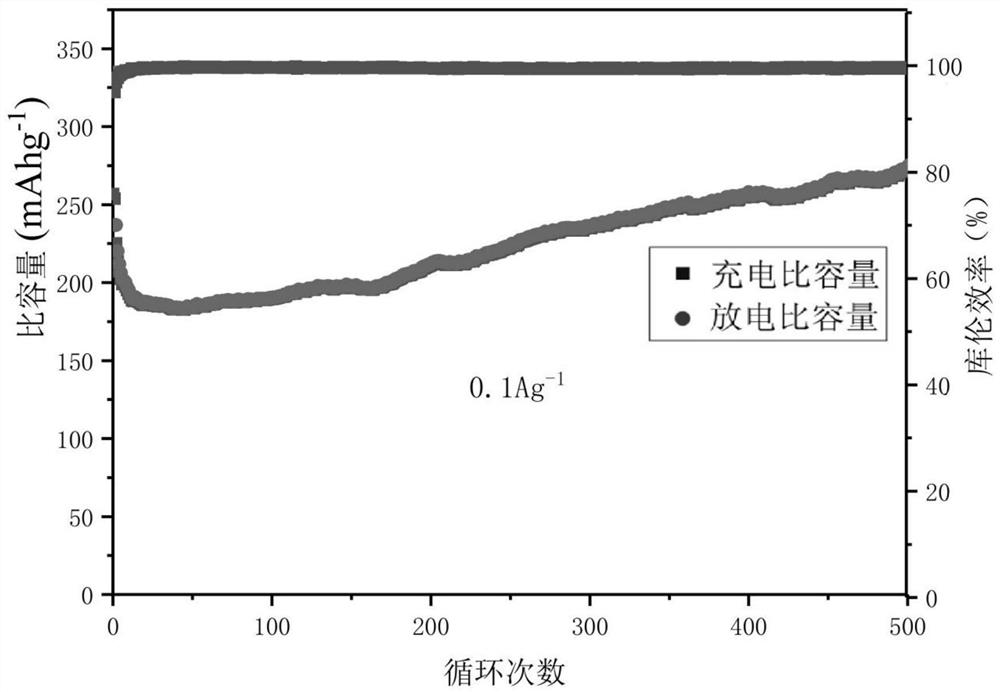

Embodiment 1

[0055] Weigh titanium powder, niobium powder, aluminum powder and carbon powder according to the molar ratio of 2:1:1.4:1.8; the particle diameters of the four kinds of powders are 300 mesh, wet mix the four kinds of powders with alcohol for 30min, and then Vacuum drying at ℃ for 12 hours; pre-press the mixed powder at 2kN for 2 minutes; then adjust the vacuum degree of the atmosphere to 10Pa, the sintering pressure to 50MPa, and raise the temperature to 1450℃ at a heating rate of 50℃ / min and keep it for 60min. Spark plasma sintering to obtain niobium-doped Ti 3 AlC 2 .

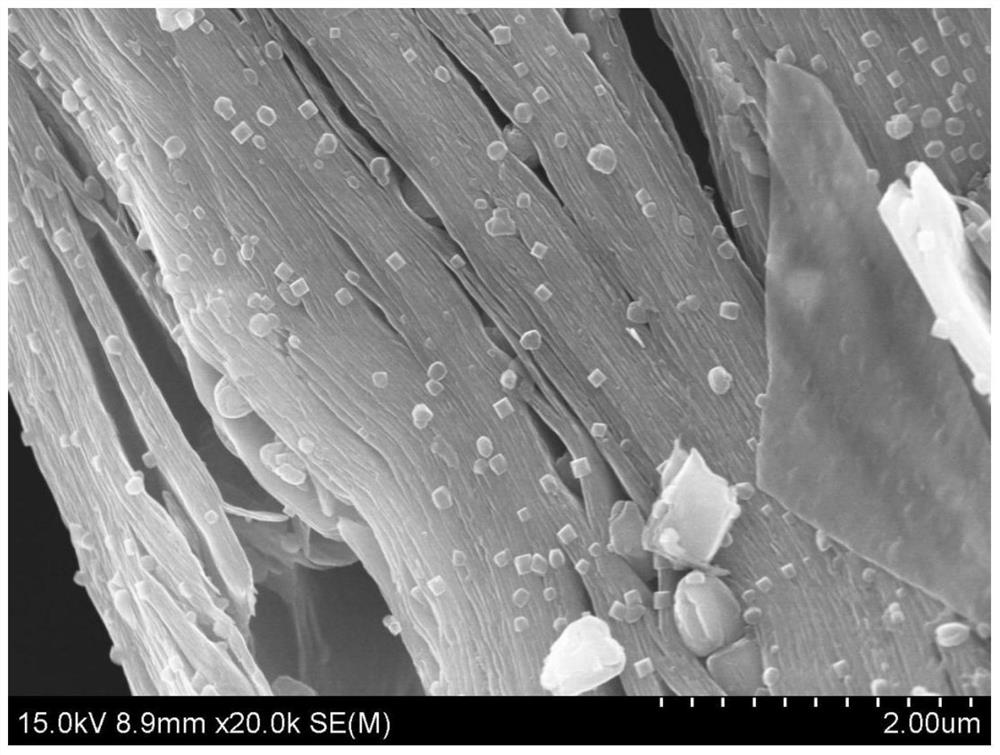

[0056] Niobium doped Ti 3 AlC 2 Pulverize, select powder between 300 mesh and 2000 mesh, use HF with a mass fraction of 50% to etch for 24 hours, and heat in a water bath at a temperature of 50°C to obtain niobium-doped two-dimensional layered titanium carbide, denoted as Ti 2 NbC 2 ;

[0057] 0.5g Ti 2 NbC 2 Put it into a porcelain boat, put it into a tube furnace, and seal the tube furnace; in an ai...

Embodiment 2

[0064] Weigh titanium powder, niobium powder, aluminum powder and carbon powder according to the molar ratio of 2:1:1.4:1.8; the particle diameters of the four kinds of powders are 300 mesh, wet mix the four kinds of powders with alcohol for 30min, and then Vacuum drying at ℃ for 12 hours; pre-press the mixed powder at 2kN for 2 minutes; then adjust the vacuum degree of the atmosphere to 10Pa, the sintering pressure to 50MPa, and raise the temperature to 1450℃ at a heating rate of 50℃ / min and keep it for 60min. Spark plasma sintering to obtain niobium-doped Ti 3 AlC 2 .

[0065] Niobium doped Ti 3 AlC 2 Pulverize, select powder between 300 mesh and 2000 mesh, use HF with a mass fraction of 50% to etch for 24 hours, and heat in a water bath at a temperature of 50°C to obtain niobium-doped two-dimensional layered titanium carbide, denoted as Ti 2 NbC 2 ;

[0066] 0.5g Ti 2 NbC 2 Put it into a porcelain boat, put it into the tube furnace and seal the tube furnace well. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com