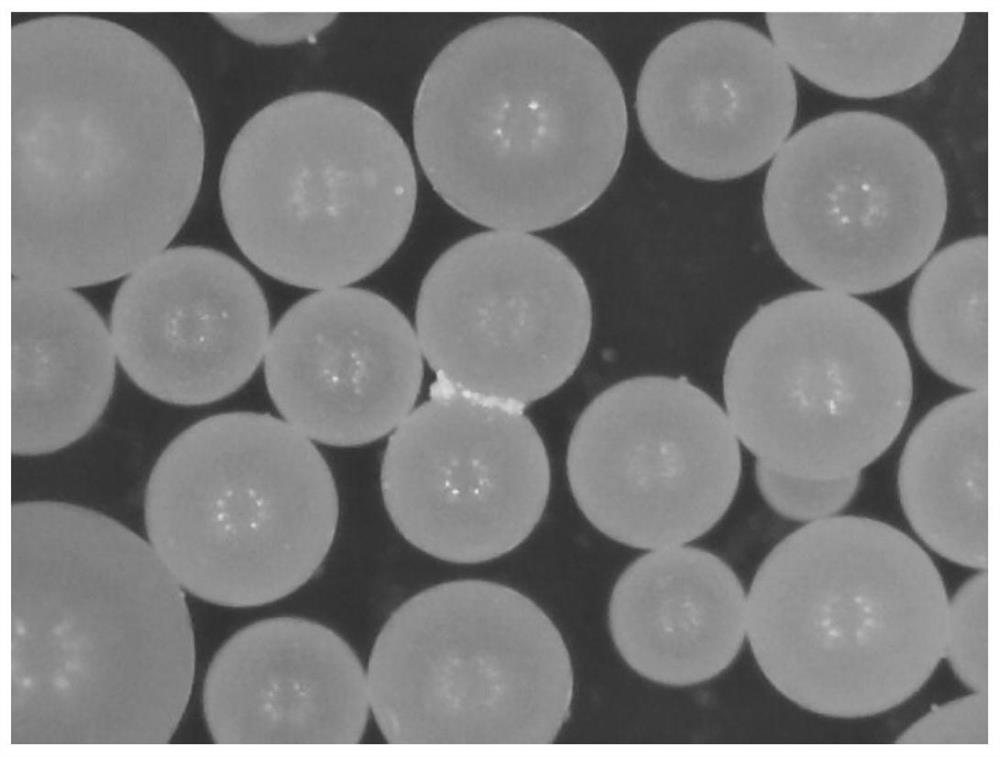

Coenzyme Q10, VD3 and VK2 sugar vitrified microcapsules and preparation method thereof

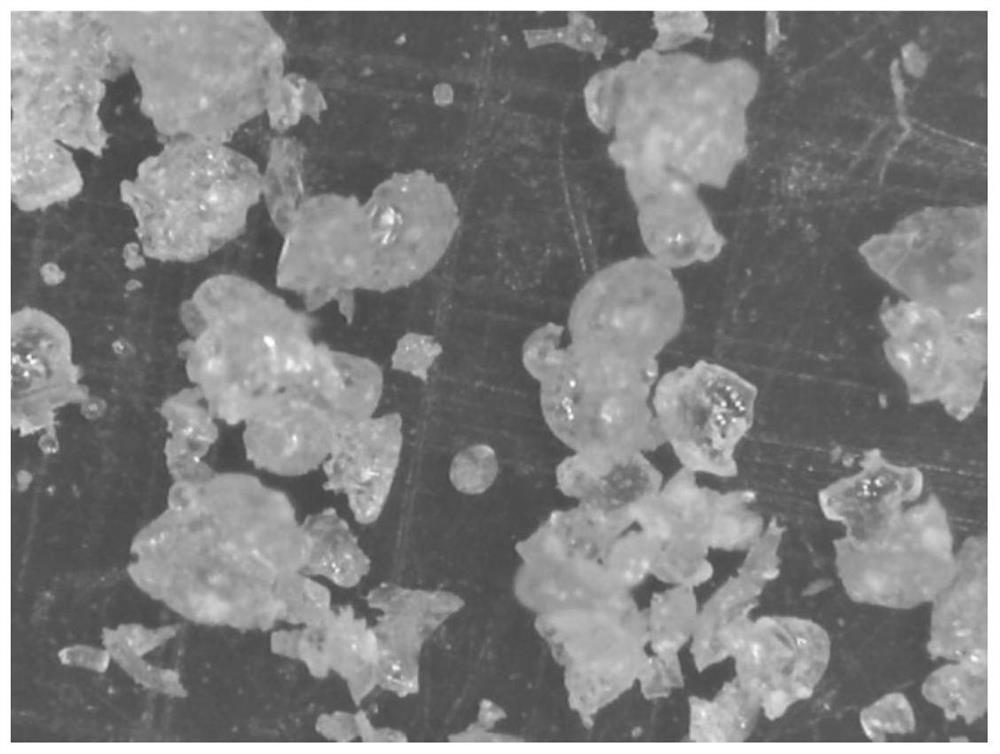

A sugar vitrification and microencapsulation technology, applied in the field of vitamins, can solve the problems of poor aqueous solution and stability, low yield of microcapsules, easy to agglomerate in rehydration, etc., and achieves improved uniformity, high microencapsulation efficiency, and good water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the sugar vitrified microcapsules provided by the invention comprises the following steps:

[0039] (1) The core material and the wall material are mixed to form an emulsion, the core material contains coenzyme Q10, VD3 and VK2, and the wall material contains starch sodium octenyl succinate, carbohydrate compound, pH value regulator and enhancer Plasticizer, the viscosity of the starch sodium octenyl succinate at 25°C is 20-100mPa·s, and the DE value of the carbohydrate compound is >16;

[0040] (2) Pass supercritical CO into the emulsion 2 fluid, at a temperature and pressure sufficient to make supercritical CO 2 The fluid is maintained under supercritical conditions for a period of time so that the supercritical CO 2 The fluid dissolves in the wall material causing the wall material to swell, followed by rapid pressure release allowing the wall material to solidify around the core material, resulting in sugar vitrified microcapsules.

[00...

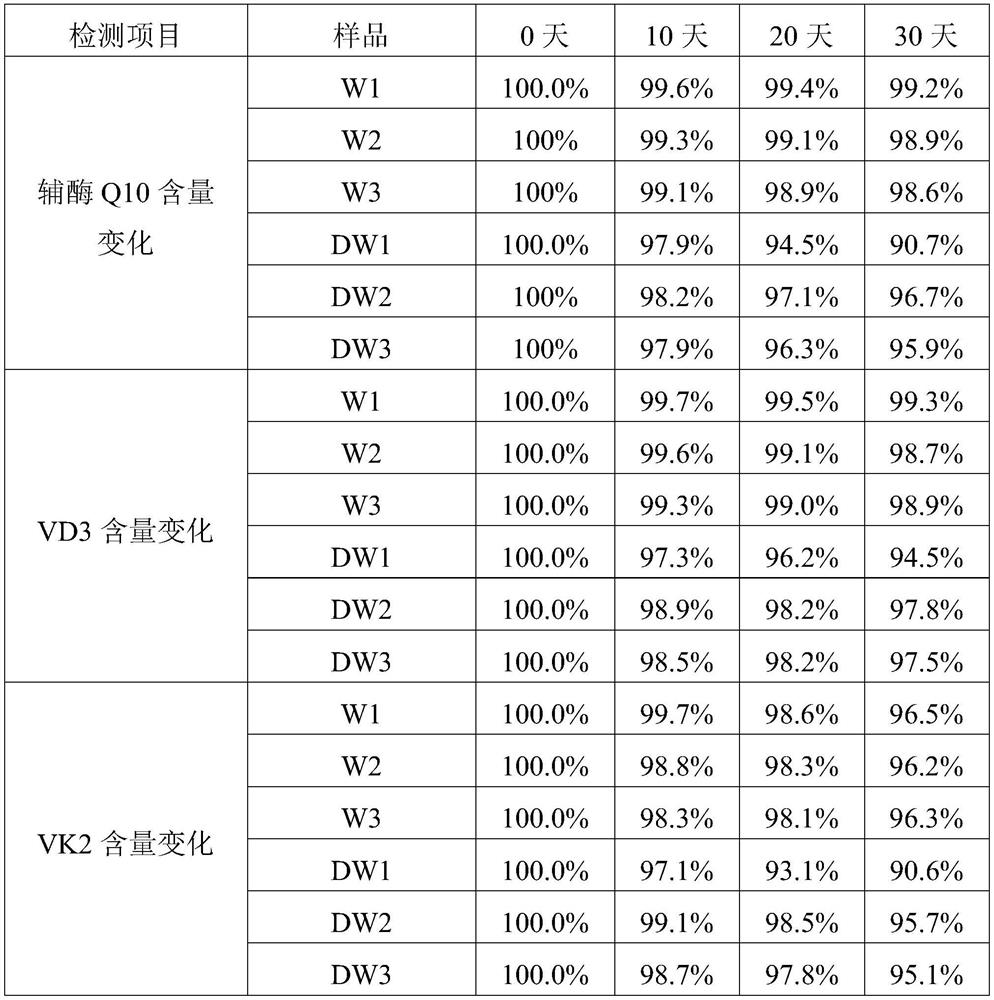

Embodiment 1

[0048] (1) Melt 55g of coenzyme Q10 crystals, 0.04g of VD3 crystals, 2.0g of VK2 oil, 5g of glyceryl monostearate, 87.76g of MCT oil, and 0.2g of rosemary extract in an oil-dissolving pot at 40°C to obtain coenzyme Q10 , VD3, VK2 oil phase liquid. Mix 200g sodium starch octenyl succinate (the viscosity at 25°C is 72mPa·s, the same below), 300g maltodextrin (Roquette, DE18-20, the same below), 300g solid corn syrup powder (Bowling Bio , DE30-50, the same below), 5g sodium citrate, 5g sodium ascorbate, 40g glycerin were dissolved in 600g water, heated to 40°C and kept warm to obtain an aqueous phase solution. Add the above coenzyme Q10, VD3, VK2 oil phase solution into the water phase solution, shear at 10000rpm for 20min, and get the oil droplet size D 50 Coenzyme Q10, VD3, VK2 emulsion of 0.762μm and viscosity of 180mPa·s.

[0049] (2) Add the above coenzyme Q10, VD3, VK2 emulsion into supercritical CO 2 In the fluid granulation equipment, supercritical CO 2 Fluid, the tem...

Embodiment 2

[0052] (1) Melt 105g of coenzyme Q10 crystals, 0.07g of VD3 crystals, 4.0g of VK2 oil, 5g of monoglyceride citrate, 30.43g of MCT oil, and 0.5g of rosemary extract in an oil-dissolving pot at 50°C to obtain coenzyme Q10, VD3, VK2 oil phase liquid. Dissolve 205g sodium starch octenyl succinate, 300g maltodextrin, 270g solid corn syrup powder, 10g sodium citrate, 10g sodium ascorbate, and 60g glycerin in 600g water, heat to 50°C and keep it warm to obtain an aqueous phase solution. Add the above coenzyme Q10, VD3, VK2 oil phase solution into the water phase solution, shear at 10000rpm for 20min, and get the oil droplet size D 50 Coenzyme Q10, VD3, VK2 emulsion of 0.815μm and viscosity of 190mPa·s.

[0053] (2) Add the above coenzyme Q10, VD3, VK2 emulsion into supercritical CO 2 In the fluid granulation equipment, supercritical CO 2 Fluid, the temperature is controlled at 30°C and the pressure is controlled at 40MPa for 20min, so that the supercritical CO 2 The fluid dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com